Nanofiber composite membrane containing plant source antibacterial agents, preparation method and application of nanofiber composite membrane

A nanofiber and composite film technology, which is applied in the fields of nanomaterials and food packaging materials, can solve problems such as unreported research on antibacterial nanofiber films, and achieve the effects of long-lasting antibacterial effect, simple operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of nanofiber composite film, concrete steps are as follows:

[0040] (1) Dissolve 6g of polyvinyl alcohol in 100mL of distilled water, stir at 80°C for 3 hours to obtain a 6% polyvinyl alcohol solution, and cool to room temperature;

[0041] (2) Inhale the spinning solution obtained in (1) into a 10mL syringe, install a needle with a diameter of 0.6mm, adjust the distance from the needle to the receiver to 16cm, adjust the voltage at 20kV, the temperature at 27°C, the humidity at 60%, and the flow rate control Spinning at 0.6mL / h for 4h, and then vacuum drying at 35°C for 12h to obtain a 6% polyvinyl alcohol nanofiber composite membrane.

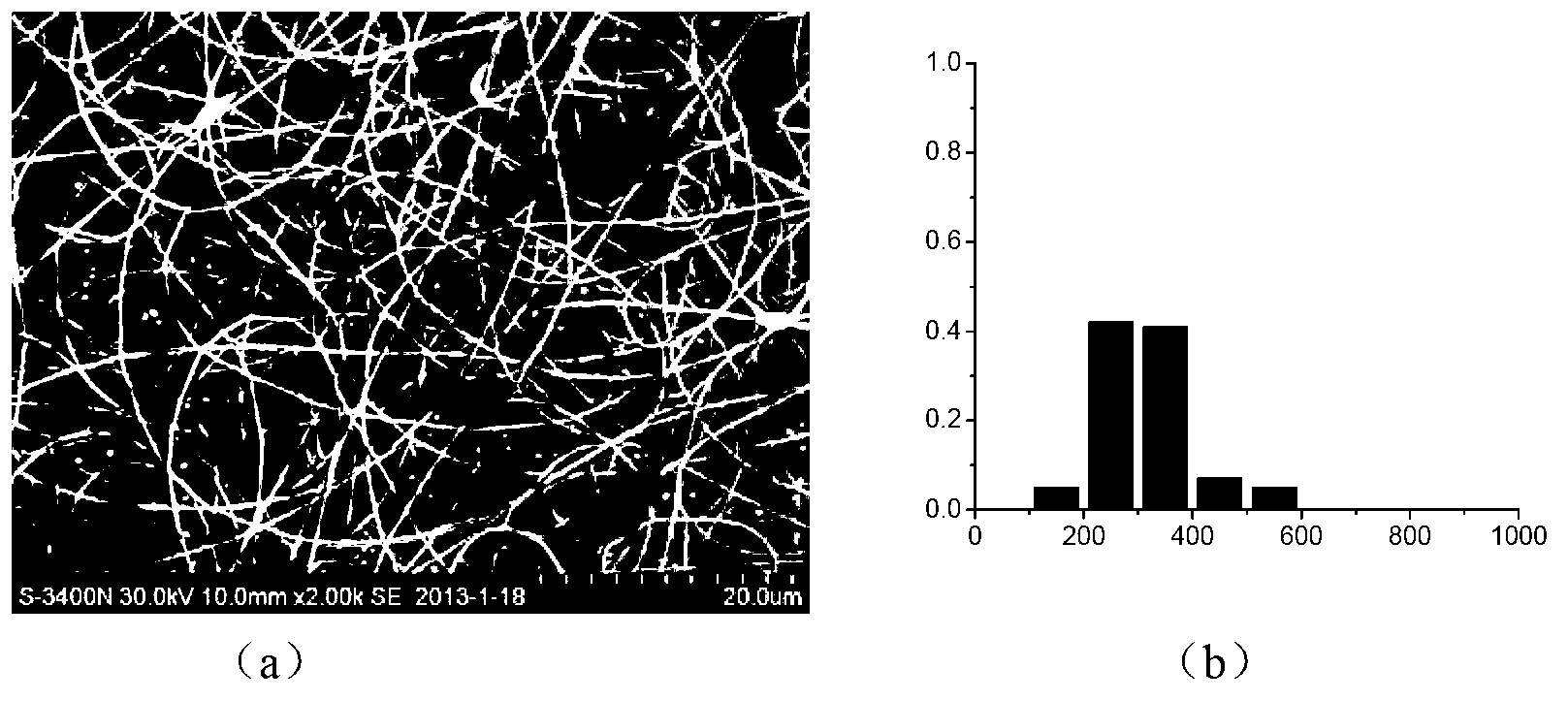

[0042] The SEM and particle size distribution of the nanofibrous membrane prepared under the above process conditions are shown in figure 1 .

Embodiment 2

[0044] A preparation method of a nanofiber composite film containing a plant-derived antibacterial agent, the specific steps are as follows:

[0045] (1) Dissolve 6g of polyvinyl alcohol in 100mL of distilled water and stir at 80°C for 3 hours to obtain a 6% polyvinyl alcohol solution;

[0046] (2) After the solution obtained in (1) was cooled to 30°C, 5 mL of cinnamon essential oil was added thereto, and stirred at 30°C for 2 hours to obtain the desired spinning solution.

[0047] (3) Inhale the spinning solution obtained in (2) into a 10mL syringe, install a needle with a diameter of 0.6mm, adjust the distance from the needle to the receiver to 15cm, adjust the voltage at 20kV, the temperature at 24°C, the humidity at 58%, and the flow rate control Spinning at 0.5mL / h for 4h, and then vacuum drying at 35°C for 12h, the antibacterial nanofiber composite film of 6% polyvinyl alcohol + 5% cinnamon essential oil was obtained.

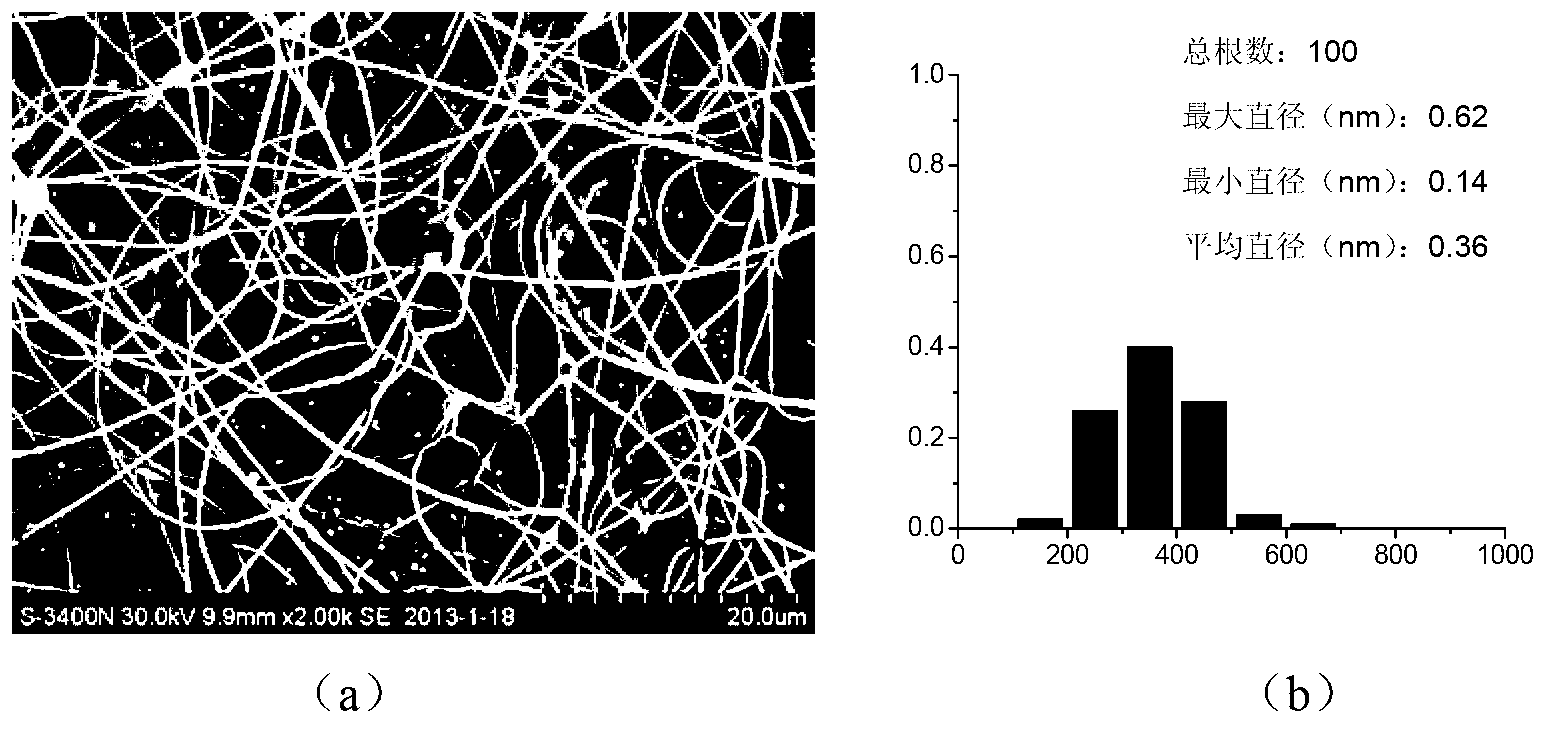

[0048] The SEM and particle size distribution of t...

Embodiment 3

[0050] A preparation method of a nanofiber composite film containing a plant-derived antibacterial agent, the specific steps are as follows:

[0051] (1) Dissolve 6g of polyvinyl alcohol in 100mL of distilled water and stir at 80°C for 3 hours to obtain a 6% polyvinyl alcohol solution;

[0052] (2) After cooling the polyvinyl alcohol solution obtained in (1) to 50°C, add 2g of β-cyclodextrin and stir at room temperature for 1 hour to obtain a spinning solution of 6% polyvinyl alcohol + 2% β-cyclodextrin;

[0053] (3) After the solution obtained in (2) was cooled to 30°C, 5g of cinnamon essential oil was added thereto, and stirred at 30°C for 2h to obtain the desired spinning solution.

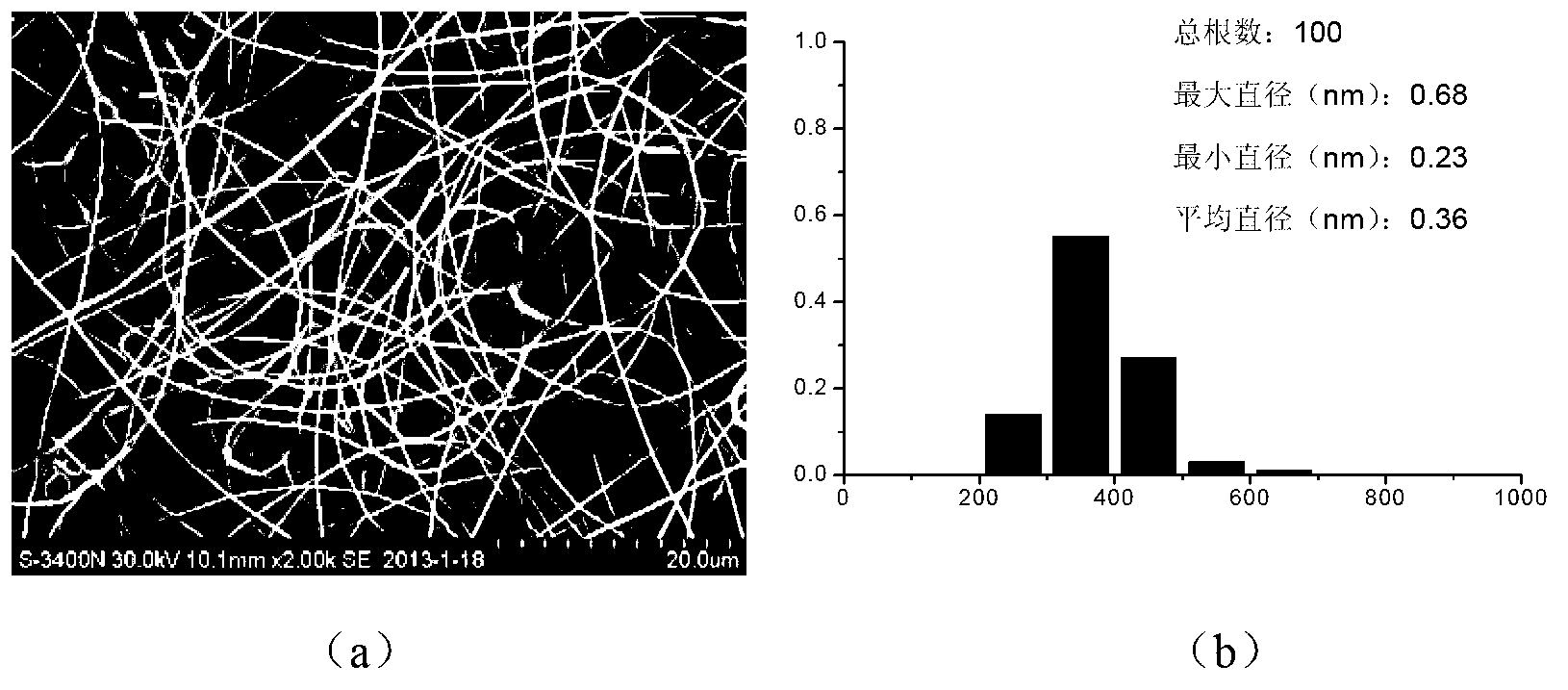

[0054] (4) Inhale the spinning solution obtained in (3) into a 10mL syringe, install a needle with a diameter of 0.6mm, adjust the distance from the needle to the receiver to 14cm, adjust the voltage to 15kV, the temperature to 27°C, the humidity to 60%, and the flow rate to be controlled Spin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com