Water-based anti-static bonding agent for shoes and preparation method thereof

A water-based, anti-static technology, applied in the field of rubber processing, can solve the problems of low production environment safety, harm to human health, flammability of rubber slurry, etc., and achieve the effects of good adhesion performance, low cost and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

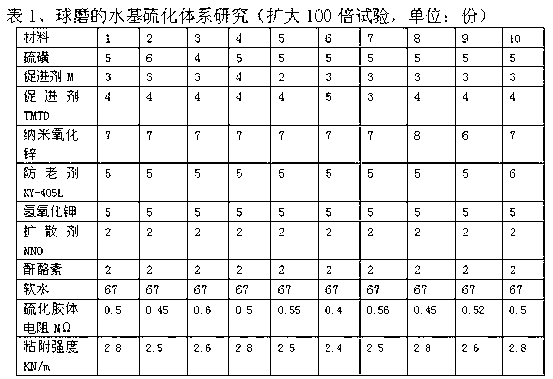

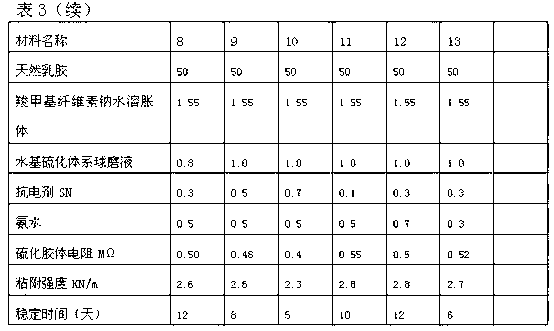

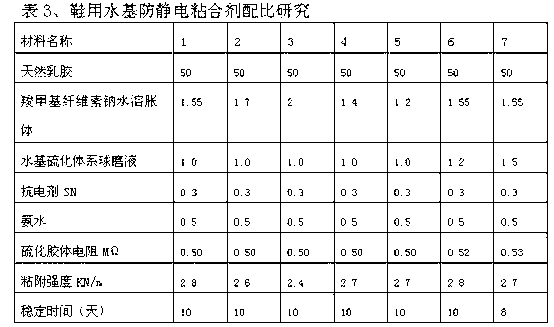

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 of the present invention: water-based antistatic adhesive for shoes, including 50kg natural latex, 1kg ball-milled water-based vulcanization system, 0.5kg ammonia water, 0.5kg flat plus O, 0.3kg antistatic agent SN and 0.05kg carboxymethyl Base cellulose sodium and 1kg soft water; every 1kg ball milled water-based vulcanization system consists of 0.05kg sulfur, 0.03kg accelerator M, 0.04kg accelerator TMTD, 0.07kg nano-zinc oxide, 0.05kg anti-aging agent KY-405L, 0.05kg hydrogen Potassium oxide, 0.02kg diffusing agent NNO (powder), 0.02kg casein anhydride (powder) and 0.67kg soft water; the ammonia water used is industrial ammonia water, and the mass percentage of ammonia is 27%.

[0027] The preparation method of water-based antistatic adhesive for shoes, each component is taken according to the above weight, the preparation method is as follows:

[0028] Step A, preparation of sodium carboxymethyl cellulose water-swellable body: sodium carboxymethyl cellu...

Embodiment 2

[0033] Embodiment 2 of the present invention: Water-based antistatic adhesive for shoes, including 45kg natural latex, 1.2kg ball-milled water-based vulcanization system, 0.4kg ammonia water, 0.6kg flat plus O, 0.25kg antistatic agent SN and 0.06kg carboxylate Sodium methylcellulose and 0.8kg soft water; every 1kg ball milled water-based vulcanization system consists of 0.05kg sulfur, 0.03kg accelerator M, 0.04kg accelerator TMTD, 0.07kg nano zinc oxide, 0.05kg anti-aging agent KY-405L, 0.05 kg potassium hydroxide, 0.02kg diffusing agent NNO (powder), 0.02kg casein anhydride (powder) and 0.67kg soft water; the ammonia water used is industrial ammonia water, and the mass percentage of ammonia is 27%.

[0034] The preparation method is the same as in Example 1.

Embodiment 3

[0035] Embodiment 3 of the present invention: Water-based antistatic adhesive for shoes, including 55kg natural latex, 0.8kg ball-milled water-based vulcanization system, 0.6kg ammonia water, 0.4kg flat plus O, 0.35kg antistatic agent SN and 0.04kg carboxylate Sodium methylcellulose and 1.2kg soft water; every 1kg ball milled water-based vulcanization system consists of 0.05kg sulfur, 0.03kg accelerator M, 0.04kg accelerator TMTD, 0.07kg nano zinc oxide, 0.05kg anti-aging agent KY-405L, 0.05 kg potassium hydroxide, 0.02kg diffusing agent NNO (powder), 0.02kg casein anhydride (powder) and 0.67kg soft water; the ammonia water used is industrial ammonia water, and the mass percentage of ammonia is 27%.

[0036] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com