Hydrotalcite-loaded nanometer platinum catalyst as well as preparation method and application thereof

A technology of hydrotalcite and catalyst is applied in the field of metal nano-catalyst preparation, which can solve the problems of easy migration, aggregation, multi-energy, and time-consuming, and achieve the effects of high cinnamyl alcohol product selectivity, improved interaction and enhanced stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

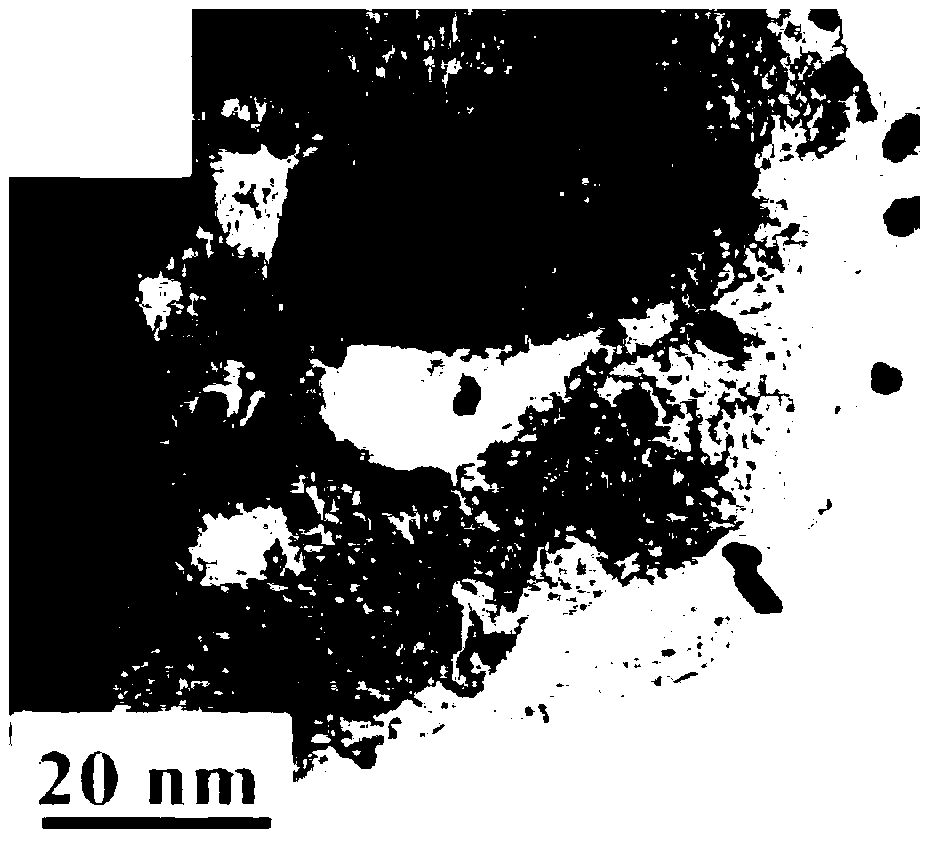

Image

Examples

Embodiment 1

[0027] Weigh 1.536gMg(NO 3 ) 2 ·6H 2 O and 1.125gAl(NO 3 ) 3 9H 2 O was dissolved in 30mL deionized water to prepare a mixed salt solution, weighing 0.576gNaOH and 0.636gNaOH 2 CO 3Prepare 30mL of mixed alkali solution, wherein the molar concentration of NaOH is (Mg 2+ +Al 3+ ) 1.6 times the sum of the concentrations, Na 2 CO 3 Concentration is Al 3+ 2 times the concentration.

[0028] Pour the prepared mixed salt solution and mixed alkali solution into the fully back-mixed liquid film reactor at room temperature. The speed of the liquid film reactor is 4500 rpm, and rotate back-mixed for 3 minutes to obtain a hydrotalcite suspension, which is centrifuged and washed with water. After 1 time, redisperse the precipitate in 80mL of water; add 3mL of chloroplatinic acid solution with a concentration of 10mmol / L to the hydrotalcite suspension, and then add TTAB, wherein the molar ratio of TTAB to chloroplatinic acid is 50:1 , heated to 60°C, stirred for 10min; then NaBH...

Embodiment 2

[0032] Weigh 2.304gMg(NO 3 ) 2 ·6H 2 O and 1.125gAl(NO 3 ) 3 9H 2 O was dissolved in 30mL deionized water to prepare a mixed salt solution, weighing 0.72gNaOH and 0.954gNaOH 2 CO 3 Prepare 30mL of mixed alkali solution, wherein the molar concentration of NaOH is (Mg 2+ +Al 3+ ) 1.5 times the sum of the concentrations, Na 2 CO 3 Concentration is Al 3+ 3 times the concentration.

[0033] Pour the prepared mixed salt solution and mixed alkali solution into the fully back-mixed liquid film reactor at room temperature. The speed of the liquid film reactor is 4200 rpm, and rotate back-mixed for 4 minutes to obtain a hydrotalcite suspension, which is centrifuged and washed with water. After 2 times, redisperse the precipitate in 60mL of water; add 5mL of chloroplatinic acid solution with a concentration of 10mmol / L into the hydrotalcite suspension, and then add TTAB, wherein the molar ratio of TTAB to chloroplatinic acid is 25:1 , warming up to 60 ° C, stirring for 15 min...

Embodiment 3

[0037] Weigh 3.072gMg(NO 3 ) 2 ·6H 2 O and 1.125gAl(NO 3 ) 3 9H 2 O was dissolved in 30mL deionized water to prepare a mixed salt solution, weighing 1.08gNaOH and 0.636gNaOH 2 CO 3 Prepare 30mL of mixed alkali solution, wherein the molar concentration of NaOH is (Mg 2+ +Al 3+ ) 1.8 times the sum of the concentrations, Na 2 CO 3 Concentration is Al 3+ 2 times the concentration.

[0038] Pour the prepared mixed salt solution and mixed alkali solution into the fully back-mixed liquid film reactor at room temperature. The speed of the liquid film reactor is 4000 rpm, and rotate back-mixed for 2 minutes to obtain a hydrotalcite suspension, which is centrifuged and washed with water. After 1 time, redisperse the precipitate in 50mL water; add 6mL of chloroplatinic acid solution with a concentration of 10mmol / L to the hydrotalcite suspension, and then add TTAB, wherein the molar ratio of TTAB to chloroplatinic acid is 100:1 , warming up to 50°C, stirring for 20min; then N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com