Organic silicon nano particle modified electrode, sensor piece and preparation method of electrode

A technology of nanoparticles and modified electrodes, which is applied in the fields of organosilicon nanoparticles modified electrodes and sensor devices and its preparation, can solve the problems of large nanoparticle size distribution and difficulty in obtaining organosilicon nanoparticles, etc., and achieve high functional group content, The preparation method is simple and the selectivity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Mix 40 μL ultrapure water with 32 μL 0.1mol / L hydrochloric acid, then slowly add 188 μL 3-mercaptopropyltrimethoxysilane to fully hydrolyze it, and finally add 3-mercaptopropyltrimethoxysilane with a volume ratio of 1:2.5 Dilute with ethanol, stir at room temperature for 30 minutes to form a uniform and transparent solution; weigh 0.0133g of hexadecyltrimethylammonium bromide (1:100 molar ratio to 3-mercaptopropyltrimethoxysilane) and dissolve in 1.00 mL of ethanol was then added to the above solution, and the stirring was continued for 30 min to obtain 3-mercaptopropyltrimethoxysilane sol.

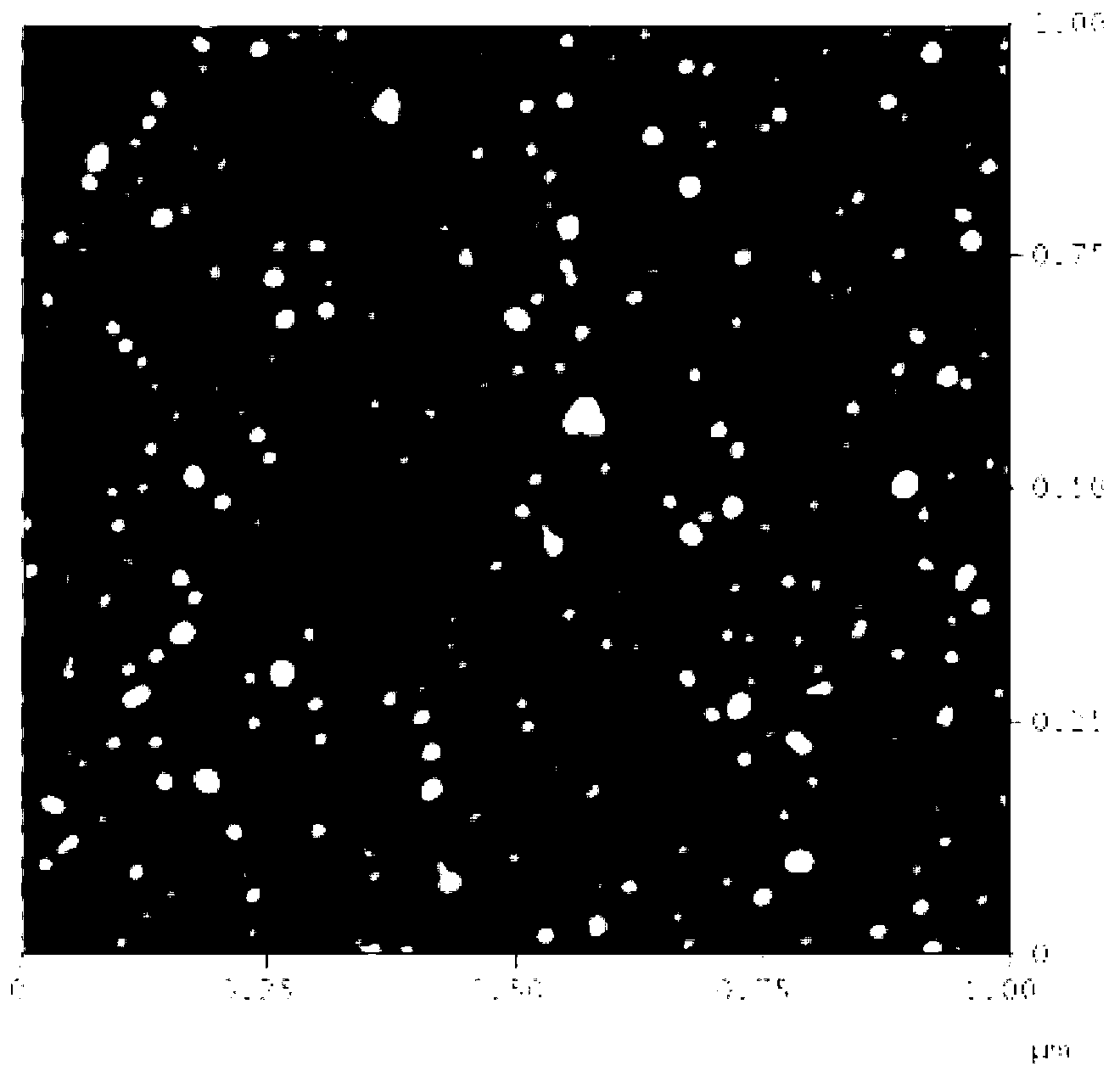

[0057] At room temperature, the cleaned gold electrode was immersed in the freshly prepared sol, self-assembled for 1 hour, removed and stabilized for 10 minutes, rinsed with ethanol, and blown dry with nitrogen. That is, the organosilicon nano film modified electrode is obtained.

[0058] Take out and stabilize for 1min, rinse with ethanol and ultrapure water in turn, and blow dr...

Embodiment 2

[0061] Immerse the cleaned gold electrode into the functionalized silicone gel in Example 1 at room temperature, self-assemble for 6 hours, take it out and stabilize it for 10 minutes, rinse with ethanol, and blow dry with nitrogen. That is, the organosilicon nano film modified electrode is obtained.

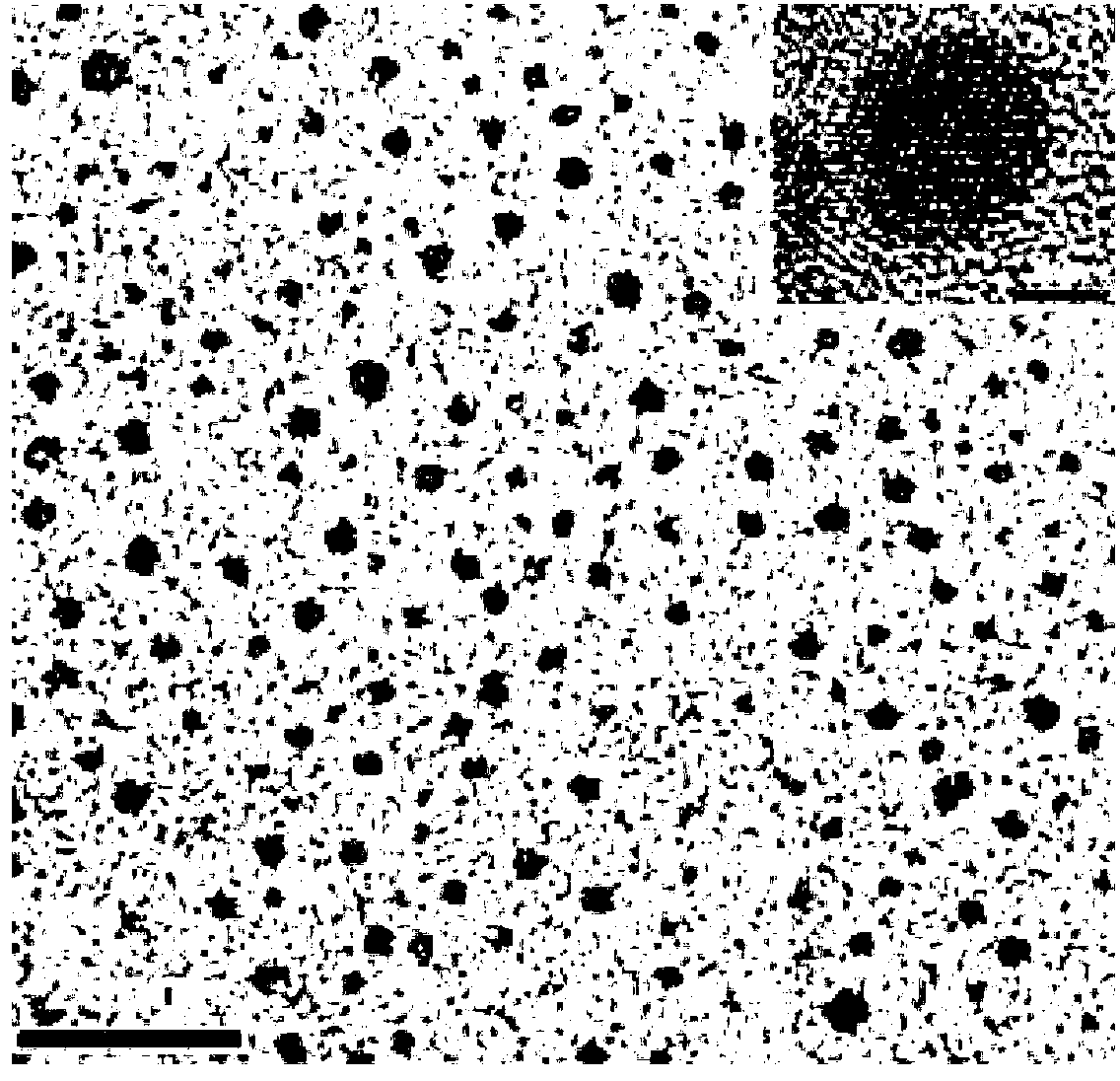

[0062] Take out and stabilize for 3 minutes, rinse with ethanol and ultrapure water in turn, and dry with inert gas; then extract in a mixture of 0.2mol / L hydrochloric acid and 99.7% ethanol by mass fraction, and the volume ratio of hydrochloric acid and ethanol is 1:1 The surfactant was removed, the extraction time was 1 h, the water was rinsed, and the nitrogen gas was blown to dry, and the mercapto-functionalized organosilicon nanoparticle-modified gold electrode was prepared.

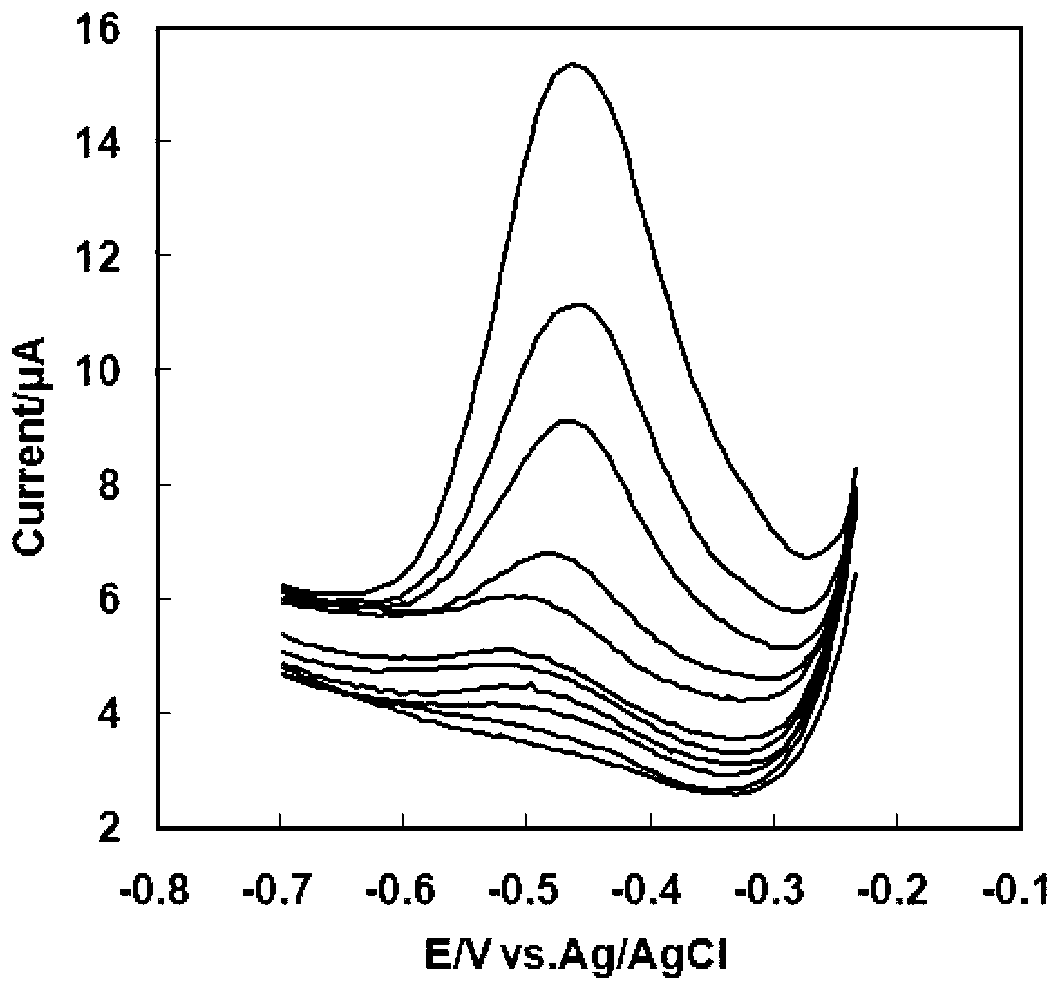

[0063] The above-mentioned modified electrode is used as the working electrode, the platinum wire is used as the auxiliary electrode, and Ag / AgCl is used as the reference electrode, and the compositio...

Embodiment 3

[0065] Mix 160 μL ultrapure water and 128 μL 0.1mol / L hydrochloric acid, then slowly add 212 μL 3-aminopropyltrimethoxysilane to fully hydrolyze it, and finally add 3-aminopropyltrimethoxysilane with a volume ratio of 1:5 Dilute with ethanol, stir at room temperature for 1h to form a uniform and transparent solution, weigh 0.0488g (1:50 molar ratio to 3-aminopropyltrimethoxysilane) sodium dodecylbenzenesulfonate and dissolve in 1.00mL ethanol , and then added to the above solution, and continued to stir for 1h to obtain 3-aminopropyltrimethoxysilane sol.

[0066] The surface-cleaned indium tin oxide electrode was immersed in the freshly prepared sol, self-assembled for 10 hours, taken out and left for 5 minutes, rinsed with ethanol, and blown dry with nitrogen. Then extract 30min in 0.05mol / L hydrochloric acid and 95% ethanol with a mass fraction of hydrochloric acid and ethanol in a volume ratio of 1:1, rinse with ultrapure water, and dry with nitrogen to obtain amino-functio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com