Method and device for multi-grade mixed combustion of double fuels at cyclone state

A combustion device and dual-fuel technology, which is applied in the direction of gaseous fuel and powder fuel combustion, combustion equipment, lighting and heating equipment, etc., can solve the problem of unsatisfactory pulverized coal burnout effect, high NOx content in flue gas, and coal type adaptation Insufficient compatibility and other issues, to achieve the effects of easy access, reduced flue gas NOx emission concentration, and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

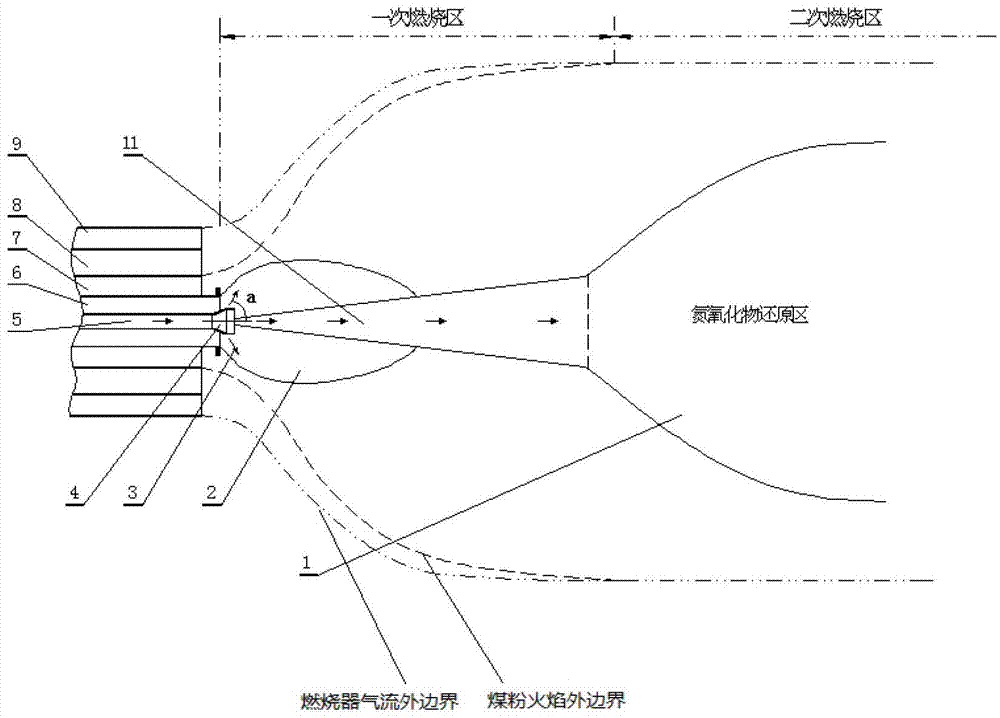

[0039] refer to figure 1 , 2 , the swirl burner of the method of the present invention is respectively arranged with auxiliary fuel central delivery pipe (5), central air passage (6), primary air passage (7), inner secondary air passage (8) and outer secondary air passage from inside to outside. Air channel (9). The auxiliary fuel central conveying pipe (5) directs the auxiliary fuel used to the central nozzle (4) at the front end of the burner, and the central air channel (6) is used to direct about 2% of the combustion air from the secondary air main pipe to the front end of the burner The central nozzle of the primary air passage (7) directs the primary air carrying pulverized coal to the primary air nozzle at the front end of the burner, and the inner and outer secondary air passages (8) and (9) direct the secondary air to the secondary air at the front end of the burner spout. The central wind is direct current, the primary air powder is direct current or weak swirl, t...

specific Embodiment 2

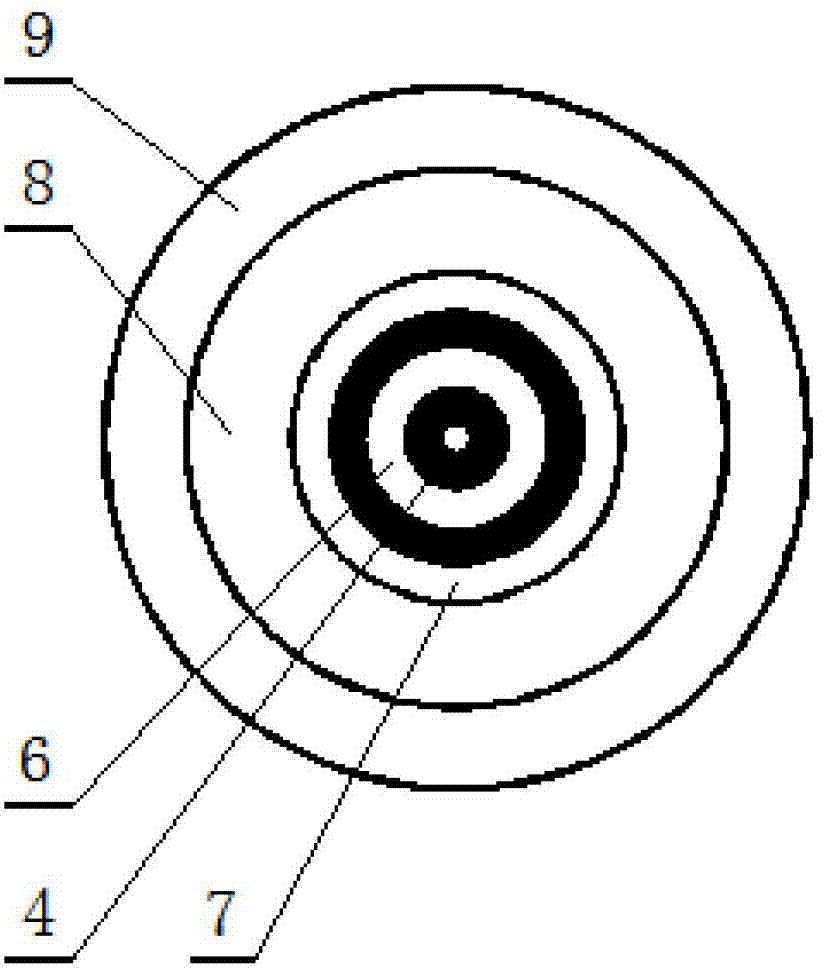

[0043] refer to image 3 , the method and the auxiliary fuel nozzle of the burner are respectively arranged at the center of the burner and at the outlet of the external secondary air passage. The injection holes for injecting the first-stage auxiliary fuel are located on the central nozzle (4), and the injection holes for injecting the second-stage auxiliary fuel are located on the outer ring nozzle (10). The difference between this implementation example and the specific implementation example 1 is that a certain number of outer ring nozzles (10) for injecting auxiliary fuel are arranged at the outlet of the outer secondary air passage, and the outer ring nozzles (10) are distributed in a circular shape, such as Figure 4 As shown, they provide the second-stage auxiliary fuel high-speed stream (12) to form the NOx reduction zone (1) as the main purpose, and at the same time can stretch the burner flame, expand the high temperature range of the furnace, and improve the heat e...

specific Embodiment 3

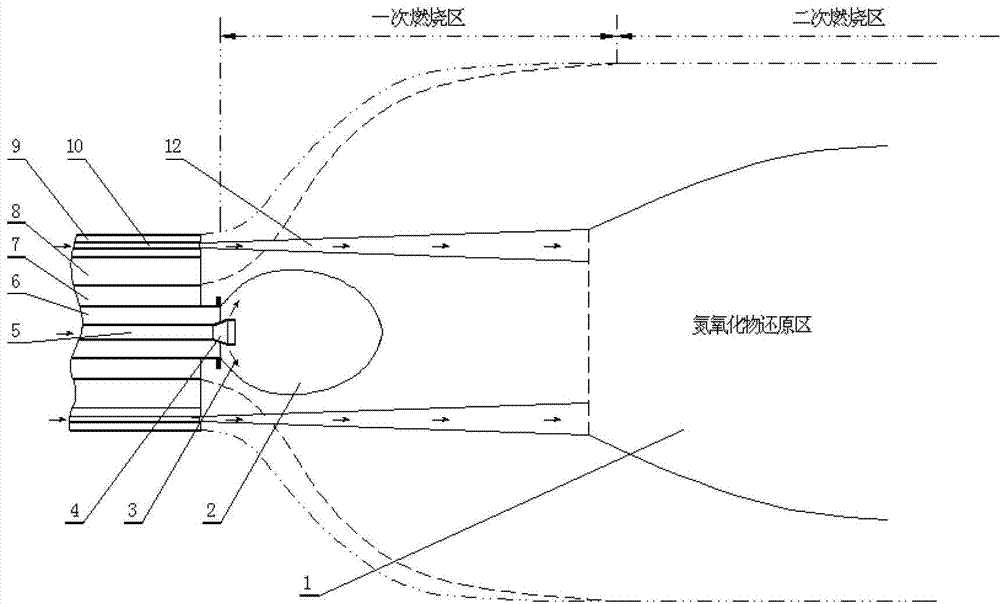

[0046] refer to Figure 5 , the auxiliary fuel nozzles of the burner are respectively arranged at the center of the burner and at the outlet of the outer secondary air channel and distributed in a ring shape. The difference between this implementation example and the specific implementation example 1 is that the second-stage auxiliary fuel, in addition to the high-speed stream (11) provided by the center nozzle hole of the center nozzle (4), also presents a Some auxiliary fuel outer ring nozzles (10) are arranged annularly, and the outer ring second-stage auxiliary fuel high-speed stream (12) is provided through the nozzle holes on the outer ring nozzles (10). The difference from the second implementation example is that the center nozzle is not only provided with a side nozzle but also a center nozzle hole to provide a second-stage auxiliary fuel center high-speed stream (11).

[0047] When the central high-speed stream (11) and the outer ring high-speed stream (12) are inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com