Low molecular hyaluronate, preparation method and purpose thereof

A hyaluronic acid salt and hyaluronic acid technology, applied in the fields of enzymology and medicinal chemistry, can solve the problems of low molecular weight HA, which is difficult to achieve, difficult to realize industrial production, low unit enzyme activity, etc., to solve the problems of high cost and low cost Lowering, high enzyme thermostability and pH stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] Example 1: Obtaining and identification of Bacillus sp. A50

[0126] 1. Acquisition of Bacillus sp. A50

[0127] Open the cover of the plate containing the enriched medium, place it in the air, collect the sedimentation bacteria in the air, cover it after about 1 hour, and place it in an incubator at 25-40°C for aerobic cultivation. After 24 hours of cultivation, Inoculate the isolated single colony in the screening medium, 25-40 ° C, 150 rpm, aerobic culture for 12-16 hours, use the method of Chinese Pharmacopoeia to measure the activity of hyaluronidase, and select the strain with the highest enzyme activity as the present invention. Bacteria, the enzyme activity of the strain can reach 10 5 IU / mL.

[0128] The composition of each medium used above is as follows:

[0129] Enrichment medium (100mL): peptone 0.2-2.0g, yeast powder 0.2-2.0g, K 2 HPO 4 ·3H 2 O 0.05-0.15g, MgSO 4 ·7H 2 O 0.05-0.15g, sodium hyaluronate 0.01-1g, agar powder 2.0g.

[0130] Screenin...

Embodiment 2

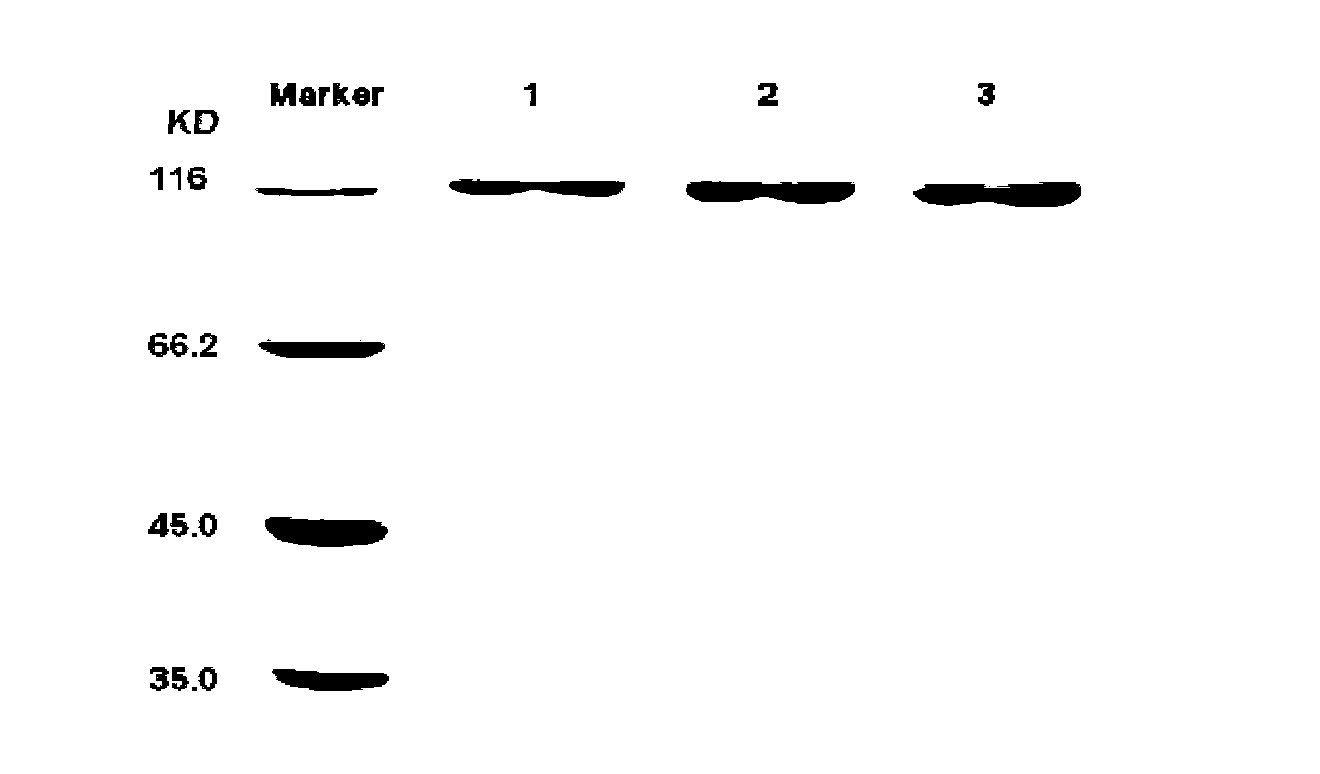

[0172] Example 2: Cloning and sequence analysis of hyaluronidase

[0173] The genomic DNA of Bacillus (Bacillus) A50 was extracted with a bacterial genomic DNA extraction kit, and the genomic DNA extraction results were detected by 1% agarose gel electrophoresis. The genome was then sequenced to obtain a whole-genome shotgun sequence of the strain. At the same time, the hyaluronidase isolated and purified from the fermentation broth of Bacillus (Bacillus) A50 was subjected to N-terminal sequencing and trypsin-degraded endopeptide sequencing to obtain a partial amino acid sequence of the hyaluronidase. Use the BLAST tool on NCBI to compare the whole genome shotgun sequence with the partial amino acid sequence, find the gene fragment with 100% similarity to the amino acid sequence, and find the approximate location of the hyaluronidase gene. Then according to the N-terminal sequence of hyaluronidase, the size of the SDS-PAGE electrophoresis band, and the analysis of the open ...

Embodiment 3

[0180] Embodiment 3: Preparation of hyaluronidase (1)

[0181] Slant medium composition (100mL): peptone 0.2g, yeast powder 2.0g, K 2 HPO 4 ·3H 2 O0.05g, MgSO 4 ·7H 2 O 0.05g, glucose 0.5g, agar powder 2.0g, adjust the pH to 6.0 with hydrochloric acid.

[0182] Seed medium composition (100mL): peptone 0.2g, yeast powder 2.0g, K 2 HPO 4 ·3H 2 O0.05g, MgSO 4 ·7H 2 O 0.05g, glucose 0.5g, adjust the pH to 6.0 with hydrochloric acid.

[0183] Fermentation medium composition (100mL): peptone 0.2g, yeast powder 2.0g, K 2 HPO 4 ·3H 2 O0.05g, MgSO 4 ·7H 2 O 0.05g, glucose 0.5g, Tween80 (Tween 80) 0.05mL.

[0184]Take the slant strain (Bacillus sp. A50 CGMCC NO.5744) and inoculate it into the sterilized seed medium, cultivate it at 25°C and 150rpm for 24 hours, then inoculate the seed liquid into the sterilized fermentation medium In the medium, the inoculum size is 10%, 25°C, 200rpm culture for 24 hours, the pH is maintained at 6.0 with sulfuric acid during the fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com