Preparation method of block polymer immobilized enzyme

A technology of block polymer, immobilized enzyme, applied in the direction of immobilization on/in organic carrier, biochemical fiber treatment, non-woven fabric, etc. The process of immobilizing enzymes is cumbersome and other problems, so as to achieve a good microenvironment, improve biological activity and stability, and improve the utilization rate of enzymes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

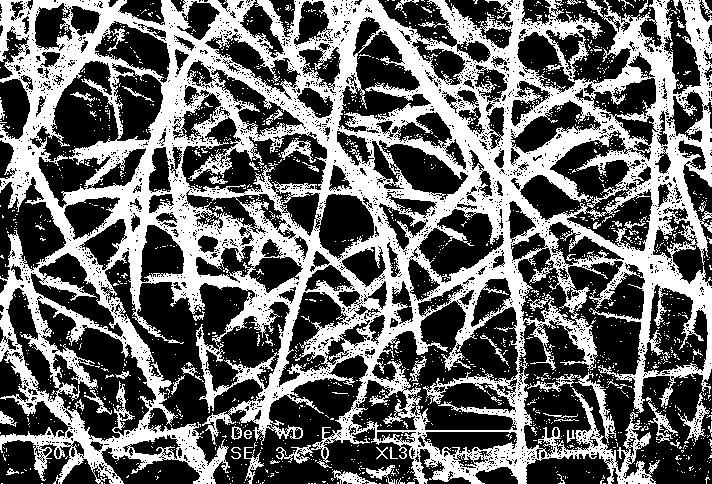

[0022] 1. Dissolve 1 gram of polymethyl methacrylate-ethyl acrylate block polymer in N,N-dimethylformamide and tetrahydrofuran solution with a mass ratio of 1:1 to form a 5% solution by weight , after being fully dissolved, inject it into the electrospinning device, carry out electrospinning under the condition that the voltage is 18 kV, the flow rate of the spinneret solution is 0.5 ml / hour, and the receiving distance is 15 cm, and the fiber diameter is 200 nm. For the methyl methacrylate-ethyl acrylate nanofiber membrane, the nanofiber membrane was dried in a vacuum oven at 30° C. for 5 hours.

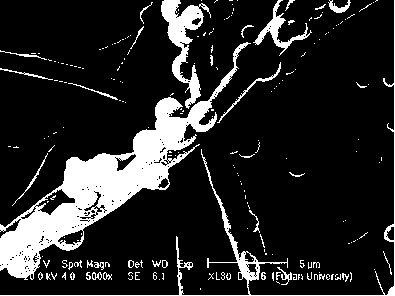

[0023] 2. Immerse 1 gram of polymethyl methacrylate-ethyl acrylate nanofiber membrane in 4% polyethylenediamine aqueous solution, seal it and shake it at a constant temperature of 70°C for 1 hour at a speed of 50 rpm ; Take out the nanofiber membrane and rinse it fully with a phosphate buffer solution with a pH of 7.0 to remove the residual polyethylenediamine on the membrane; immers...

Embodiment 2

[0025] 1. Dissolve 1 gram of polymethyl methacrylate-ethyl acrylate block polymer in N,N-dimethylformamide and tetrahydrofuran solution with a mass ratio of 1:4 to form a 10% solution by weight , after being fully dissolved, inject it into the electrospinning device, carry out electrospinning at a voltage of 25 kV, a flow rate of the spinneret solution of 1.5 ml / hour, and a receiving distance of 20 cm to obtain a fiber diameter of 300 nm. For the methyl methacrylate-ethyl acrylate nanofiber membrane, the nanofiber membrane was dried in a vacuum oven at 50° C. for 10 hours.

[0026] 2. Immerse 1 gram of polymethyl methacrylate-ethyl acrylate nanofiber membrane in 8% polyethylenediamine aqueous solution, seal it and shake it at a constant temperature of 70°C for 2 hours at a speed of 80 rpm ; Take out the nanofibrous membrane and rinse it fully with a phosphate buffer solution with a pH of 7.0 to remove the residual polyethylenediamine on the membrane; immerse the aminated nanof...

Embodiment 3

[0029] 1. Dissolve 1 gram of polymethyl methacrylate-ethyl acrylate block polymer in N,N-dimethylformamide and tetrahydrofuran solution with a mass ratio of 1:2 to form a solution with a weight percentage of 8%. , after being fully dissolved, inject it into the electrospinning device, carry out electrospinning under the condition that the voltage is 15 kV, the flow rate of the spinneret solution is 0.8 ml / hour, and the receiving distance is 15 cm, and the fiber diameter is 300 nm. For the methyl methacrylate-ethyl acrylate nanofiber membrane, the nanofiber membrane was dried in a vacuum oven at 30° C. for 5 hours.

[0030]2. Immerse 1 gram of polymethyl methacrylate-ethyl acrylate nanofiber membrane in 6% polyethylenediamine aqueous solution, seal it and shake it at a constant temperature of 70°C for 1.5 hours at a speed of 60 rpm ; Take out the nanofibrous membrane and rinse it fully with a phosphate buffer solution with a pH of 7.0 to remove the residual polyethylenediamine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com