An indoor environment-friendly dry powder coating with wave-absorbing and flame-retardant functions and its preparation method and construction method

A dry powder coating and functional technology, applied in radiation-absorbing coatings, powder coatings, fire-retardant coatings, etc., to improve smoothness and touch, reduce the amount of additives, and facilitate packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

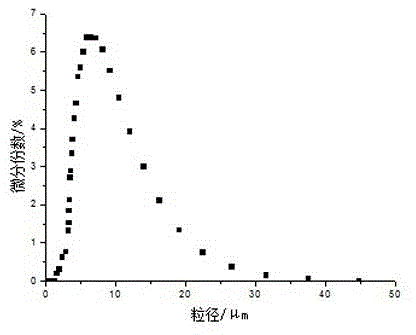

[0038] Weigh 20kg of vinyl acetate / ethylene copolymer (solid content 99%, average particle size 5μm), titanium dioxide 10kg, calcium carbonate 10kg, silicon dioxide 5kg, talcum powder 5kg, barium titanate 25kg, magnesium hydroxide (purity 96% , average particle size 1μm) 15kg, methylcellulose 6kg, antifungal agent 2kg, solid defoamer 0.7kg, anionic polyurethane 1.3kg, mixed with a horizontal mixer for 1 hour, and the powder was mixed with a 150-200 mesh vibrating sieve Sieve the material to remove large particles, weigh and pack into bags to obtain indoor environmentally friendly dry powder coatings with wave-absorbing and flame-retardant functions;

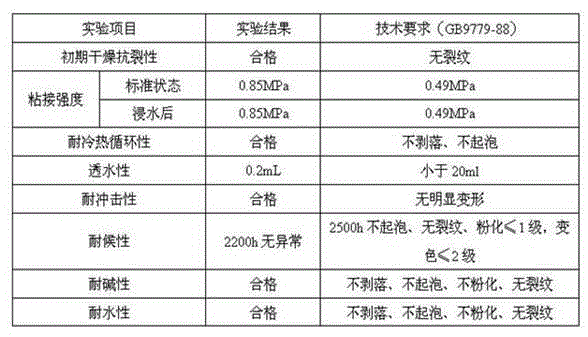

[0039] According to the construction method of the present invention, samples are taken, fully stirred with 200kg of water, and the coating film is dried to form a film. The flame retardancy level of the coating film is V0 after testing.

Embodiment 2

[0041]Weigh 24kg of vinyl acetate / higher fatty acid vinyl ester binary copolymer (solid content 98.5%, average particle size 10μm), titanium dioxide 8kg, calcium carbonate 7kg, silicon dioxide 6kg, talcum powder 7kg, ferrite 33kg, hydroxide Aluminum (purity 98%, average particle size 0.3μm) 9kg, hydroxyethyl methylcellulose 12kg, antifungal agent 3kg, solid defoamer 0.5kg, polyvinyl alcohol 2kg, iron oxide yellow 5.5kg, use a horizontal mixer Mix with the feeder for 1 hour, use a 150-200-mesh vibrating sieve to remove large particles from the powder, weigh and pack into bags to obtain an indoor environment-friendly dry powder coating with wave-absorbing and flame-retardant functions;

[0042] According to the construction method of the present invention, samples are taken, fully stirred with 200kg of water, and the coating film is dried to form a film. The flame retardancy level of the coating film is V0 after testing.

Embodiment 3

[0044] Weigh 50kg of acrylate / ethylene binary copolymer (99.5% solid content, 8μm average particle size), 5kg of titanium dioxide, 5kg of calcium carbonate, 7kg of silicon dioxide, 5kg of talcum powder, 10kg of nickel carbonyl, boehmite (purity 97 %, average particle size 3μm) 10kg, hydroxyethyl methylcellulose 5kg, antifungal agent 2kg, solid defoamer 0.1kg, polyvinyl alcohol 0.5kg, iron oxide red 0.4kg, mixed with a horizontal mixer for 1 Use a 150-200-mesh vibrating sieve to remove large particles from the powder, weigh and bag it to obtain an indoor environmentally friendly dry powder coating with wave-absorbing and flame-retardant functions;

[0045] According to the construction method of the present invention, samples are taken, fully stirred with 300kg of water, and the coating film is dried to form a film. The flame retardancy level of the coating film is V0 after testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com