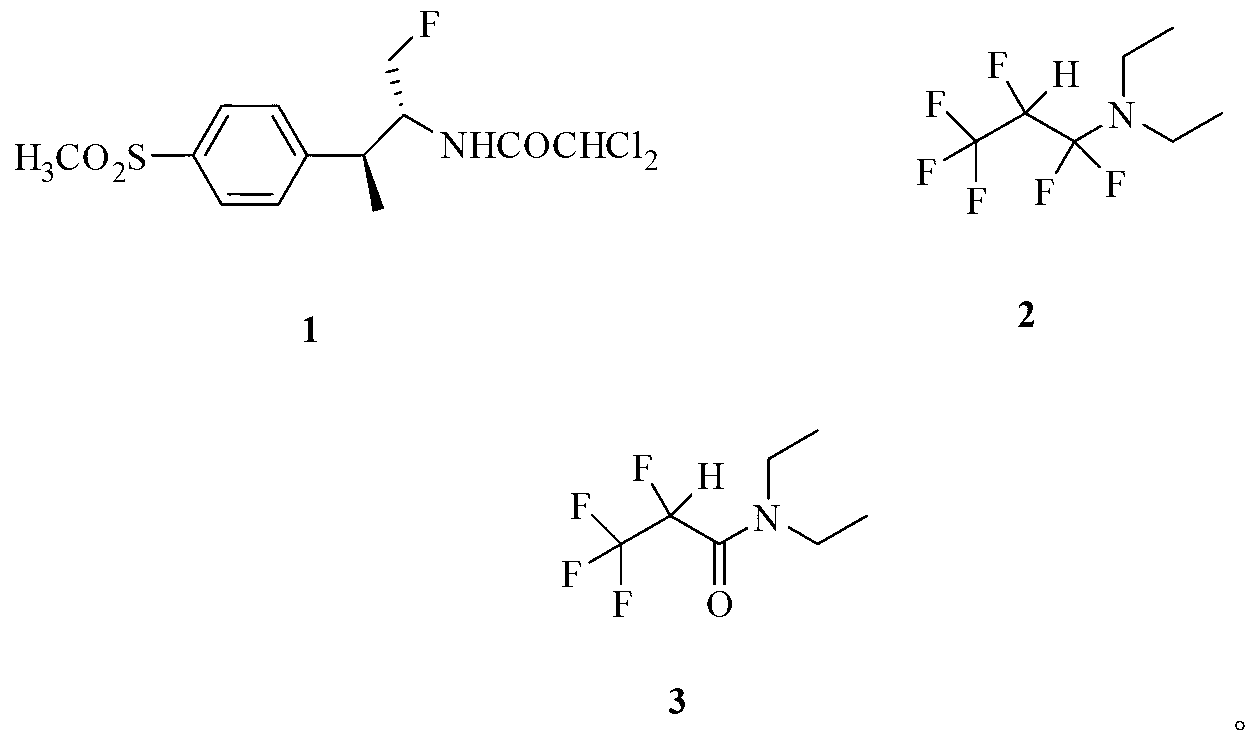

Application of fluorinating agent in florfenicol preparation technology

The technology of florfenicol and fluorinating agent is applied in the application field of fluorinating agent in the preparation process of florfenicol, which can solve the problems of high cost of fluorinating agent, difficulty in comprehensive utilization of tetrafluoropropionamide and the like, and achieve molecular weight Small, convenient for comprehensive utilization and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

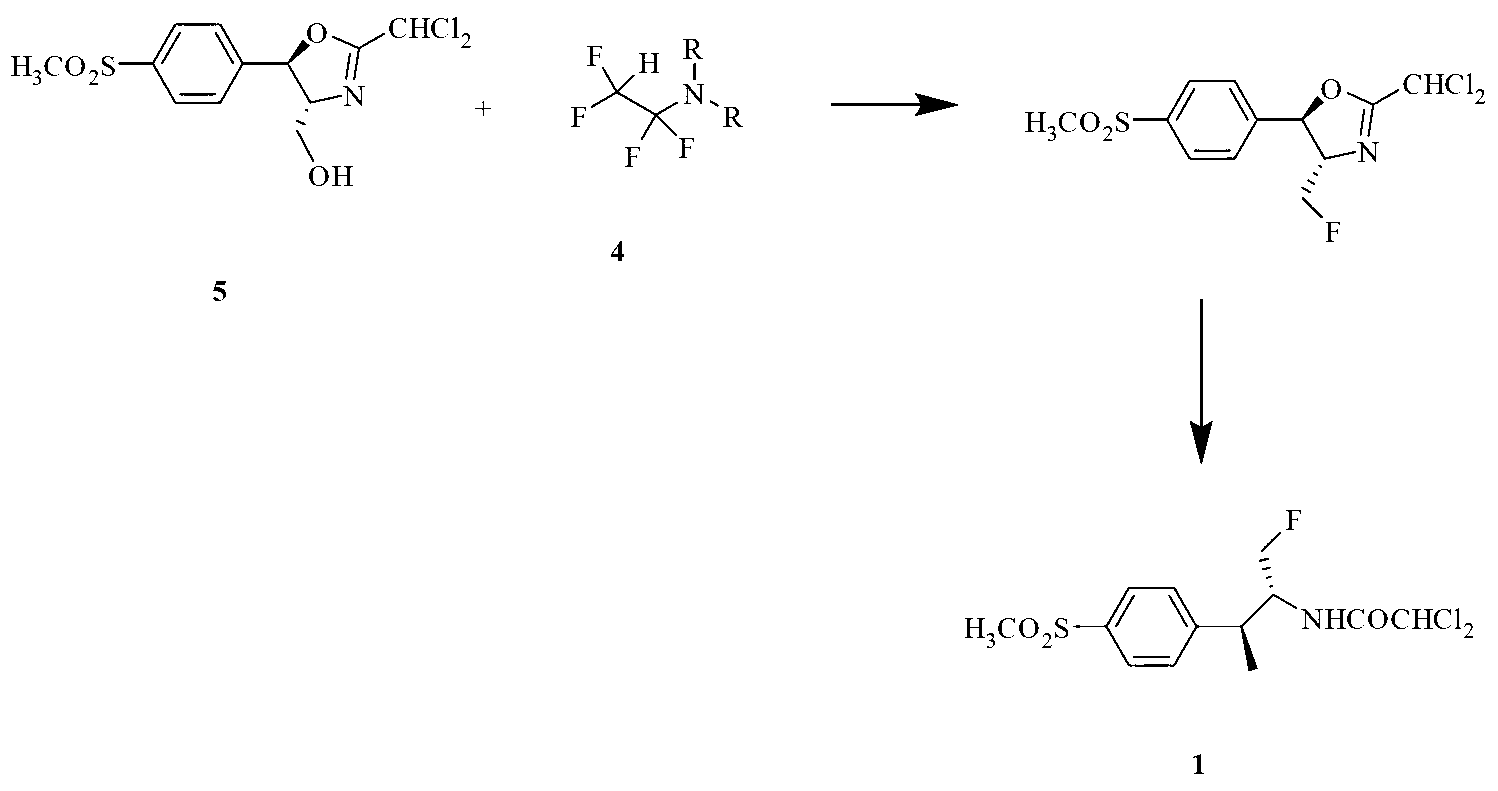

[0015] The fluorination experiment of embodiment 1 compound 5:

[0016] Reaction formula:

[0017]

[0018] Typical operation steps:

[0019] In a 1000 ml clean dry autoclave with magnetic stirring, sequentially add compound (5,50 g, 0.149 mol), solvent chloroform or dichloromethane (150 ml) and 0.238 mol of fluorinating agent (4a, 34.6 g; 4b, 41.3 g; 4c, 47.8 g), tighten the autoclave and close all valves. Start stirring and control the rotation speed at 50-80 rpm, slowly heat to 80-110°C, at this time the system pressure is below 0.9Mpa, and react for 30-60 minutes. Stop heating, keep the stirring speed at 30 rpm, and after the system temperature is lowered to room temperature, open the kettle and transfer the material liquid in the kettle to the hydrolysis reaction bottle, start stirring, and slowly add (8g of potassium fluoride, 42g of water) for fluorination Potassium aqueous solution, continue to react for 1 hour, stop the reaction. Recover chloroform or dichlorom...

Embodiment 2

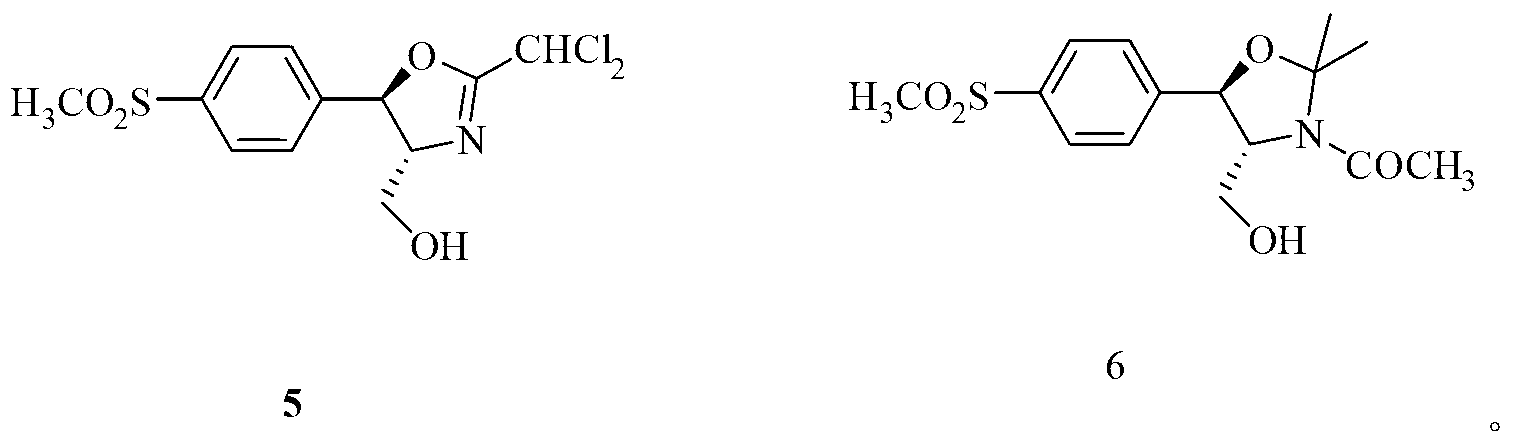

[0023] The fluorination experiment of embodiment 2 compound 6:

[0024] Reaction formula:

[0025]

[0026] Typical operation steps:

[0027] In a 1000 ml clean dry autoclave with magnetic stirring, sequentially add compound (6,50 g, 0.153 mol), solvent dichloromethane or benzene (150 ml) and 0.245 mol of fluorinating agent (4a, 35.6 g; 4b, 41.5 g; 4c, 48.2 g), tighten the autoclave and close all valves. Start stirring and control the rotation speed at 50-80 rpm, slowly heat to 80-110°C, at this time, the system pressure is below 0.7Mpa, and react for 30-60 minutes. Heating was stopped, the stirring speed was kept at 30 rpm, and after the temperature of the system was lowered to room temperature, the kettle was opened and the material liquid in the kettle was transferred to a hydrolysis reaction bottle, and after the treatment according to the method of Example 1, the crude product of Florfenicol was obtained. The reaction results are shown in the table below:

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com