Preparation method of glaze and glaze plate

A technology of glaze and fine aggregate, which is applied in the field of glaze plate preparation, can solve the problems of natural pottery clay destroying the environment, limited natural pottery clay resources, high price, etc., achieves similar color and luster, good compression resistance, and reduces carbon emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

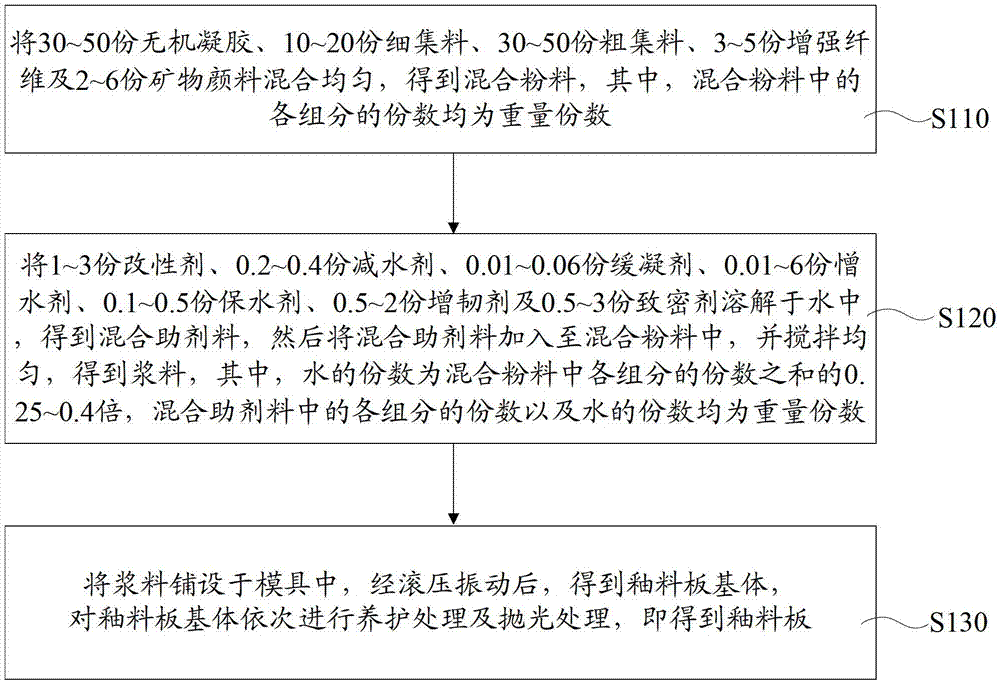

[0025] The above-mentioned glazes can be used to prepare glazed panels. This embodiment also provides a method for preparing a glaze plate using the glaze as a raw material, such as figure 1 shown, including the following steps:

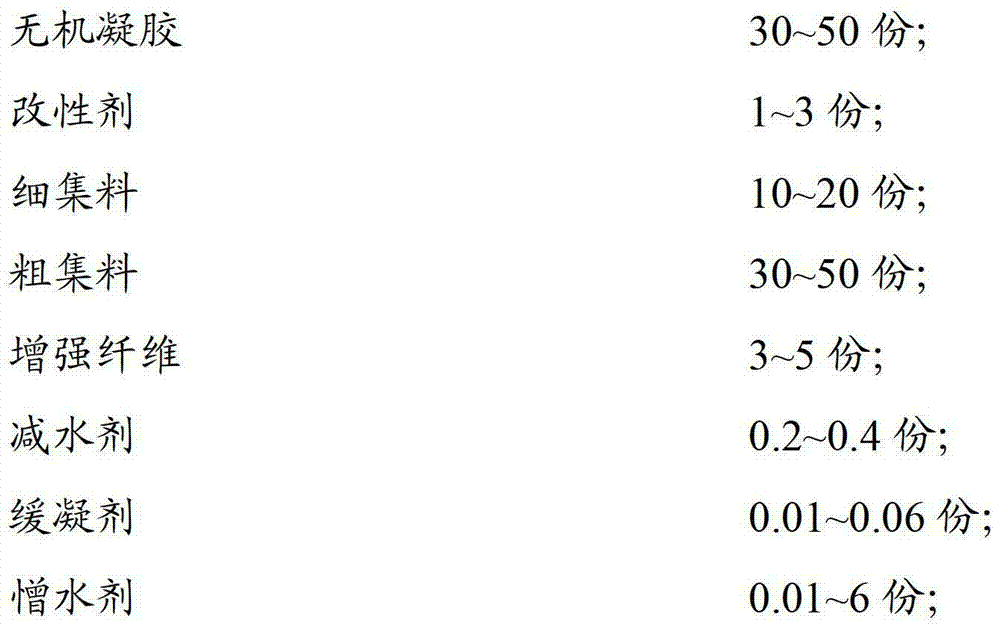

[0026] Step S110, uniformly mixing 30-50 parts of inorganic gel, 10-20 parts of fine aggregate, 30-50 parts of coarse aggregate, 3-5 parts of reinforcing fiber and 2-6 parts of mineral pigment to obtain a mixed powder, wherein , the parts of each component in the mixed powder are parts by weight.

[0027] Step S120, add 1-3 parts of modifier, 0.2-0.4 parts of water reducing agent, 0.01-0.06 parts of retarder, 0.01-6 parts of water-repellent agent, 0.1-0.5 parts of water-retaining agent, 0.5-2 parts of toughening agent and 0.5 to 3 parts of the compacting agent are dissolved in water to obtain a mixing auxiliary material, and then the mixing auxiliary material is added to the mixed powder, and stirred evenly to obtain a slurry, wherein the number of...

Embodiment 1

[0062]

[0063] (1) Portland cement, pottery clay, quartz sand, acrylic fiber and iron oxide red were weighed according to the above parts by weight, and stirred with a powerful twin-shaft mixer for 5 minutes to mix the above powders evenly to obtain mixed powders.

[0064] (2) Weigh polyvinyl alcohol powder, lignosulfonate sodium salt superplasticizer, tartaric acid, triethanolamine, hydroxypropyl methylcellulose ether, glycerol and nano-alumina sol according to the above parts by weight , and dissolving the above auxiliary materials in water to obtain a mixed auxiliary material. Then add the mixing aid material to the mixed powder, and stir for 5 minutes with a strong twin-shaft mixer to obtain a uniformly mixed slurry, wherein the number of parts of water is the sum of the parts of each component in the mixed powder. 0.25 times.

[0065] (3) Pump the slurry to the silo of the automatic paving machine. After the slurry is mixed evenly in the silo of the automatic paving ...

Embodiment 2

[0072]

[0073] (1) Weigh fly ash portland cement, gypsum, ground calcium carbonate, fly ash, rock sand, iron ore slag, alkali-resistant glass fiber and iron oxide black according to the above weight parts, and use a strong biaxial Stir with a mixer for 8 minutes to mix the above powder evenly to obtain a mixed powder.

[0074] (2) Acrylic resin rubber powder, naphthalene-based high-efficiency water reducer, borax, composite silane water repellent, carboxymethyl cellulose ether, glycerol, nano-alumina sol and nano-di Silica sol, and the above additive materials are dissolved in water to obtain a mixed additive material. Then add the mixing aid material to the mixed powder, and use a strong twin-shaft mixer to stir for 8 minutes to obtain a uniformly mixed slurry, wherein the number of parts of water is the sum of the parts of each component in the mixed powder. 0.4 times.

[0075] (3) Pump the slurry to the silo of the automatic paving machine. After the slurry is mixed e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com