Dual-core two-freedom-degree high-speed full-automatic tin soldering robot servo controller

A technology of servo controller and degree of freedom, applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve the problems of not being able to adapt to market requirements, production efficiency and product quality, not considering solder joint temperature, inconsistent solder volume, etc., to achieve The temperature and length of tin feeding are easy to control, with high degree of automation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

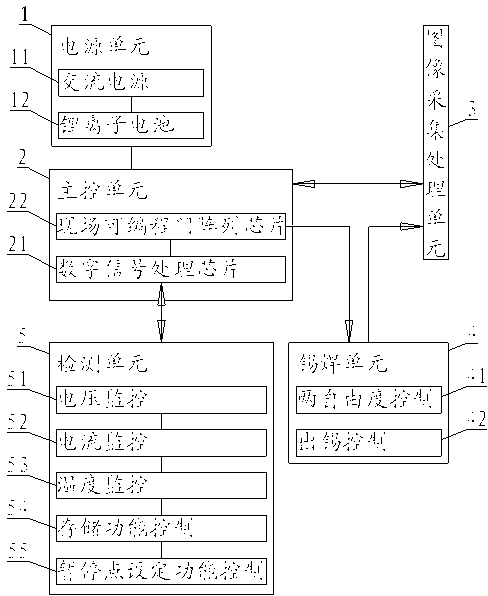

[0015] see figure 1 , a dual-core two-degree-of-freedom high-speed automatic soldering robot servo controller, comprising: a power supply unit 1, a main control unit 2, an image acquisition processing unit 3 and a soldering unit 4, the power supply unit 1 includes an AC power supply 11 and a battery , the battery is a lithium ion battery 12, the main control unit 2 includes a connected digital signal processing chip 21 and a field programmable gate array chip 22, and the soldering unit 4 includes a two-degree-of-freedom control 41 and a tin-out control 42 One end of the main control unit 2 is connected to the power supply unit 1 , the other end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com