A semi-solid flow battery

A liquid flow battery, semi-solid technology, applied in the direction of regenerative fuel cells, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of low current density of liquid flow batteries, increase the electrode reaction area, reduce contact Resistance, the effect of improving the current collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

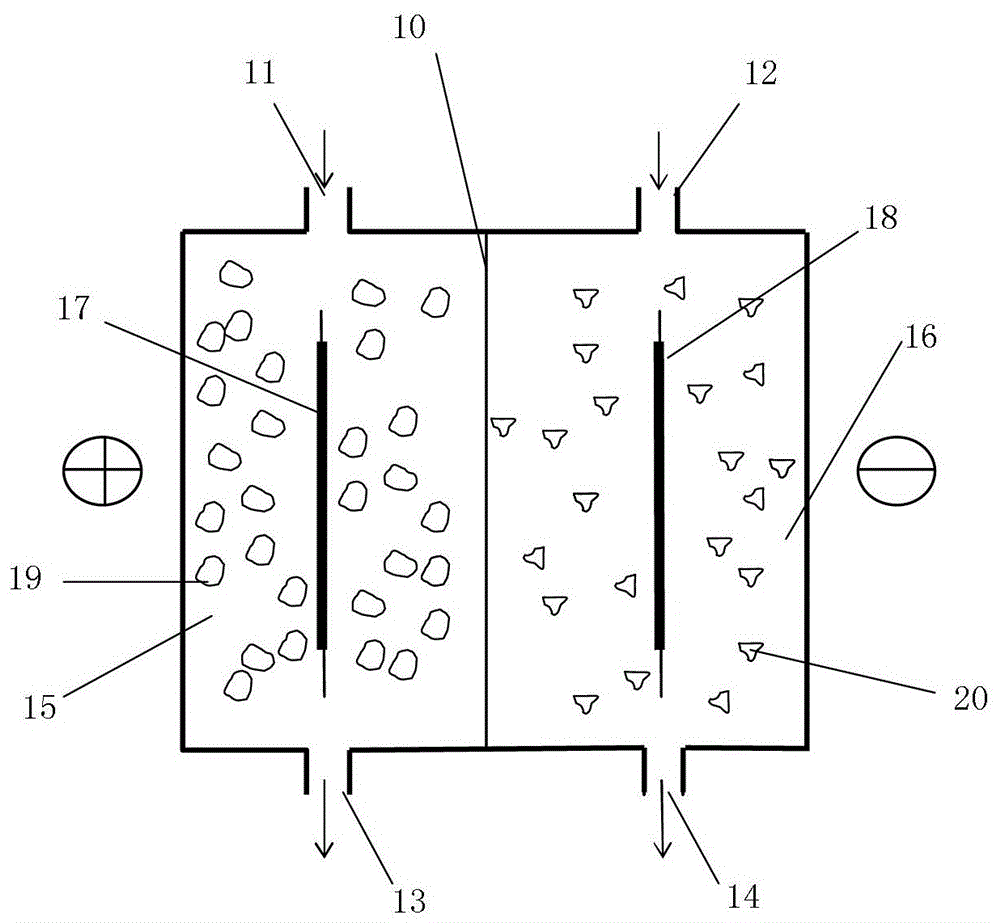

[0049] This embodiment provides a semi-solid all-vanadium redox flow battery.

[0050] A semi-solid all-vanadium redox flow battery, the semi-solid all-vanadium redox flow battery can reach a current density of 400mA / cm 2 . Among them, the positive electrolyte is VOSO 4 sulfuric acid solution, the negative electrolyte is V 2 (SO 4 ) 3 sulfuric acid solution, the active material is vanadium ions of different valence states dissolved in the electrolyte, wherein the concentration of sulfuric acid is preferably 1.5-3 mol / L, and the molar ratio of V and S elements is 1:2-3.

[0051] In this embodiment, the solid electrode particles added to the electrolyte of the semi-solid all-vanadium redox flow battery are mixed powders of graphite powder, activated carbon black powder and multi-walled carbon nanotubes.

[0052] The mixed powder preparation process is as follows:

[0053] 1) Put the hard carbon black in an environment filled with argon protective gas, and graphitize it at ...

Embodiment 2

[0060] This embodiment provides a semi-solid all-vanadium redox flow battery.

[0061] The difference from Example 1 is that the solid electrode particles added in the electrolyte are acetylene black particles loaded with tungsten oxide, and the preparation process is as follows:

[0062] 1) Heat acetylene black in a heating device at a heating rate of 5°C / min to 800°C and keep it warm for 2 hours. After cooling to room temperature naturally, wash, filter and dry with distilled water;

[0063] 2) Add 1.4g Na 2 WO 4 2H 2 Dissolve O in 14mL water, prepare a sodium tungstate solution with a mass concentration of 9%, add 1g of oxidized acetylene black, and add 16mL of 4mol / L hydrochloric acid dropwise at a speed of 3mL / min under magnetic stirring, and the solution pH=1 After adding all the hydrochloric acid and continuing to stir for 0.5h, stand and age at room temperature for 12 hours, then carry out suction filtration, washing, and drying;

[0064] 3) Then put it into the mu...

Embodiment 3

[0067] This embodiment provides a semi-solid sodium polysulfide-bromine flow battery.

[0068] A semi-solid sodium polysulfide-bromine flow battery, wherein the positive electrode electrolyte of the battery is an aqueous solution of sodium bromide (NaBr), and the added solid electrode particles are activated carbon particles with a volume content of 10%-50%; the negative electrode electrolyte Sodium polysulfide (Na 2 S x ) aqueous solution, the added solid electrode particles are carbon powder with cobalt or nickel on the surface, and the volume content is 10%-50%.

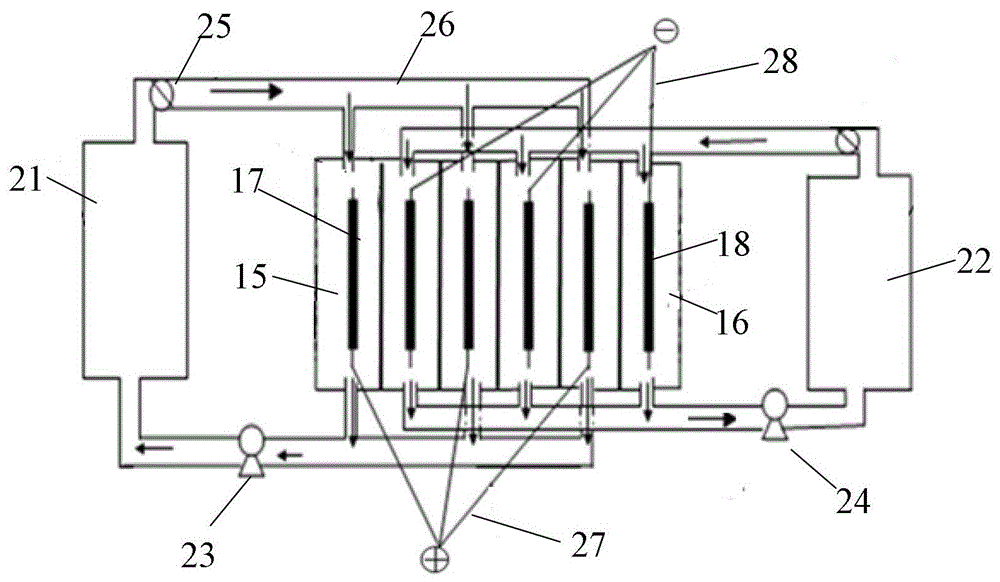

[0069] After the solid electrode particles are added to the electrolyte, they are dispersed by ultrasound to form a uniform and stable semi-solid suspension, which are stored in the positive and negative liquid storage tanks respectively, and connected to the battery stack through sealed pipes to form a circulation loop.

[0070] The positive and negative reaction chambers of the battery are separated by a catio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com