A kind of preparation method of highly active electrode material for vanadium redox flow battery

A technology for all-vanadium redox flow batteries and electrode materials, applied in battery electrodes, fuel cells, circuits, etc., can solve the problems of low electrocatalytic activity of electrode materials, achieve high practical value, less process, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put a 16cm×12cm×1.2cm polyacrylonitrile-based pre-oxygenated felt into the electric furnace, 2 and N 2 The temperature was raised to 1300°C at a rate of 10°C / min under a mixed atmosphere, CO 2 and N 2 The flow rates were 50ml / min and 350ml / min respectively, reacted at constant temperature for 1h, and then cooled to room temperature to prepare activated carbon felt.

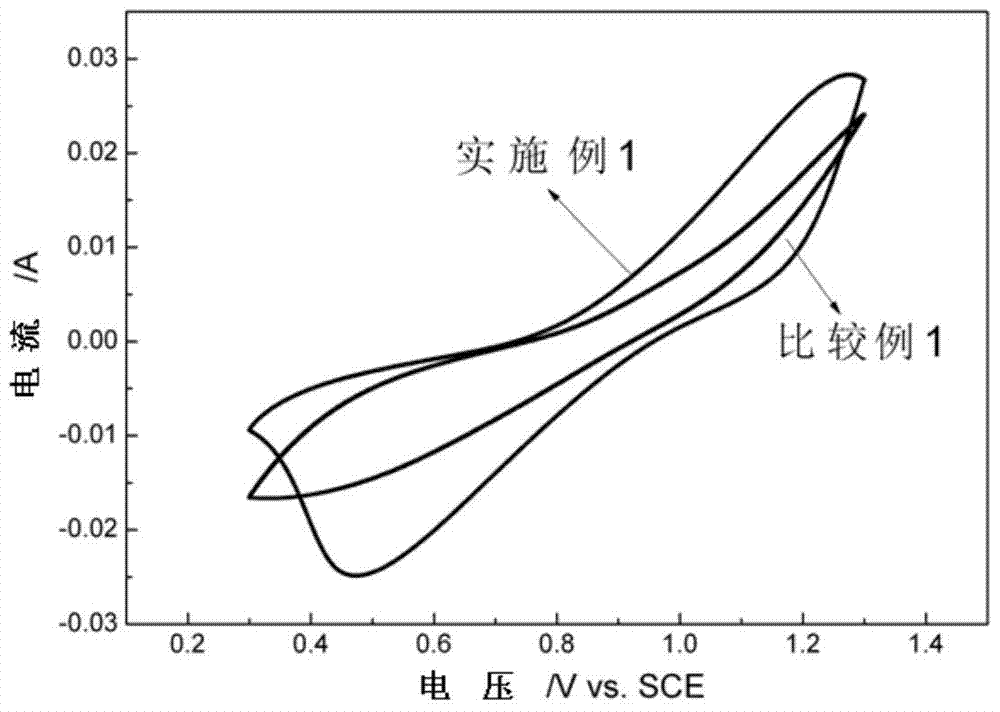

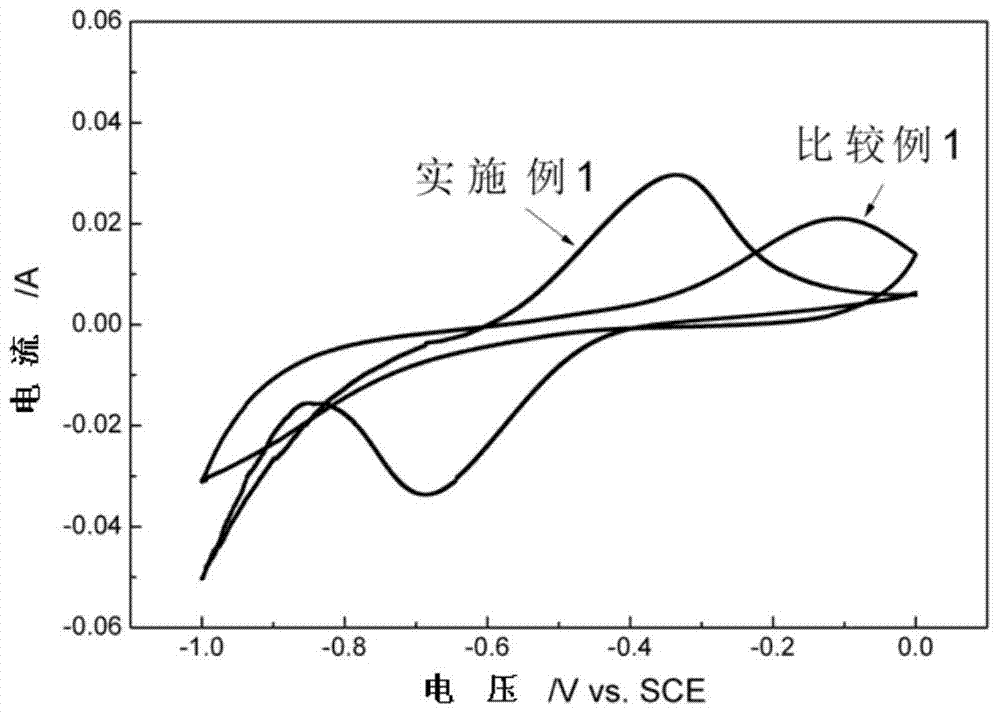

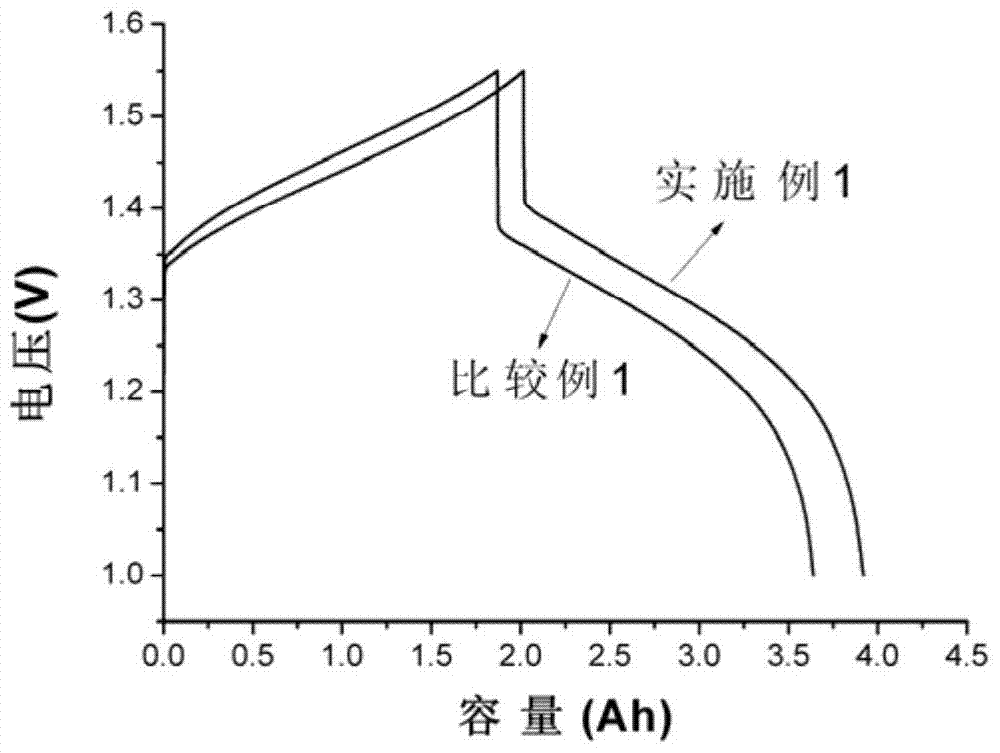

[0026] In order to test the electrochemical activity of the vanadium ion redox couple on the surface of the activated carbon felt, the activated carbon felt prepared in Example 1 was subjected to a cyclic voltammetry test. Activated carbon felt was used as the working electrode, a non-porous graphite plate was used as the counter electrode, and a saturated calomel electrode was used as the reference electrode. The electrochemical testing instrument used was the CHI612 electrochemical workstation of Shanghai Chenhua Company. The preparation concentration is 0.1M V(Ⅱ)+0.1M V(Ⅲ)+3M H 2 SO 4 and 0.1M V(Ⅳ)+...

Embodiment 2

[0037] Put a 16cm×12cm×1.2cm polyacrylonitrile-based pre-oxygenated felt into the electric furnace, 2 Under the atmosphere, the temperature was raised to 1500°C at a heating rate of 5°C / min, and then CO 2 , CO 2 and N 2 The flow rates were 100ml / min and 400ml / min respectively, reacted at constant temperature for 1h, and then cooled to room temperature to prepare activated carbon felt.

[0038] The single battery assembly evaluation conditions are the same as in Example 1, and the difference from Example 1 is that: the all-vanadium redox flow battery adopts the activated carbon felt of this example as the electrode, and the current density is 80mA / cm 2 , the voltage efficiency and energy efficiency were 90.4% and 84.7% respectively; the current density increased to 120mA / cm 2 , the voltage efficiency and energy efficiency remained at 84.9% and 80.8%, and compared with Comparative Example 2, the battery performance was greatly improved.

Embodiment 3

[0040] Put the 16cm×12cm×1.2cm viscose-based pre-oxygenated felt into the electric furnace, under N 2 Under the atmosphere, the temperature was raised to 1500°C at a heating rate of 5°C / min, and then CO 2 , CO 2 and N 2 The flow rates were 100ml / min and 400ml / min respectively, reacted at constant temperature for 1h, and then cooled to room temperature to prepare activated carbon felt.

[0041] The single battery assembly evaluation conditions are the same as in Example 1, and the difference from Example 1 is that: the all-vanadium redox flow battery adopts the activated carbon felt of this example as the electrode, and the current density is 80mA / cm 2 , the voltage efficiency and energy efficiency were 88.9% and 84.2% respectively; the current density increased to 120mA / cm 2 , the voltage efficiency and energy efficiency remained at 84.8% and 81.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com