Spalling prevention method through full-length anchoring of rib with soft bolt

A full-length anchoring and soft anchoring technology, which is applied in the installation of anchors, earthwork drilling, mining equipment, etc., can solve the problem that sparks are easily generated when cutting between the shearer drum and the metal anchor, and the coal wall can not be completely and effectively prevented. , low tensile strength of chemical slurry bolts and other problems, to achieve the effect of high friction, low cost and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

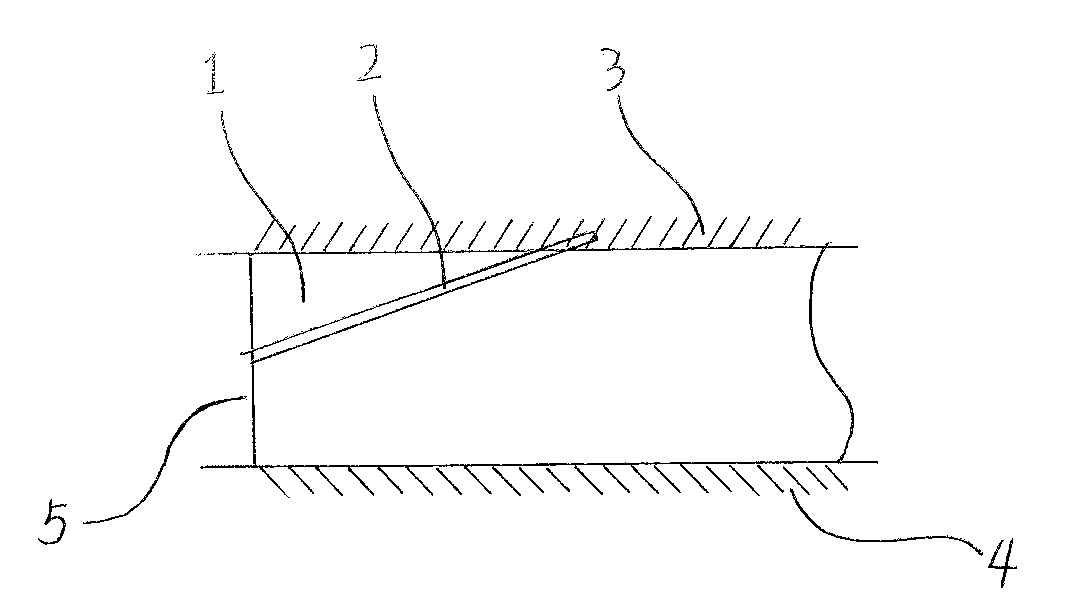

[0013] Depend on figure 1 It can be seen that the coal seam roof 3 is located at the upper part of the coal wall 1, the coal seam floor 4 is located at the lower part of the coal wall 1, the coal mining face 5 is located at the left end of the coal wall, and the borehole 2 is located obliquely inside the coal wall 1. Use the ZQJC-105 / 2.8 pneumatic column drilling rig to drill holes in the middle of the working face to the inside of the coal wall, and drill a hole every other fully mechanized mining support. The depth of the hole is 22m, the diameter of the hole is 74mm, and the end of the hole is drilled. 2 m to the interior of the coal seam roof. After the drilling construction is completed, use the grouting pipe to bind the brown rope and send the soft anchor rod filled with the brown rope to the bottom of the borehole. The diameter of the grouting pipe is 20mm, and the diameter of the brown rope is 30mm. Use ZBQ-5 / 12 pneumatic double-liquid chemical grouting pump to inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com