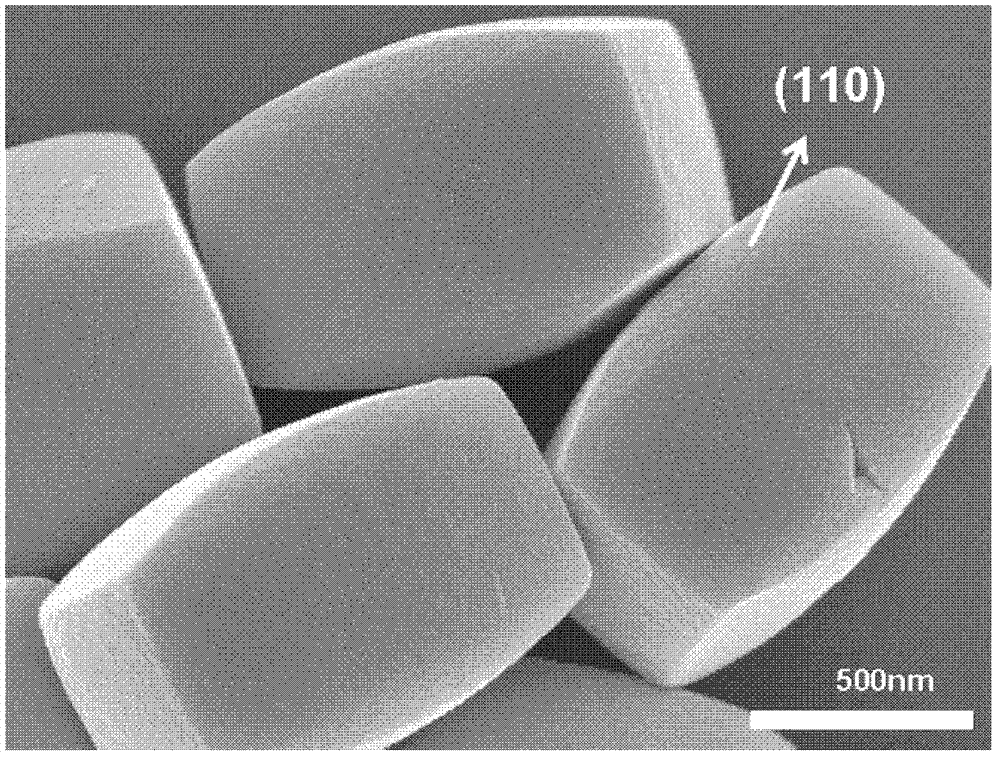

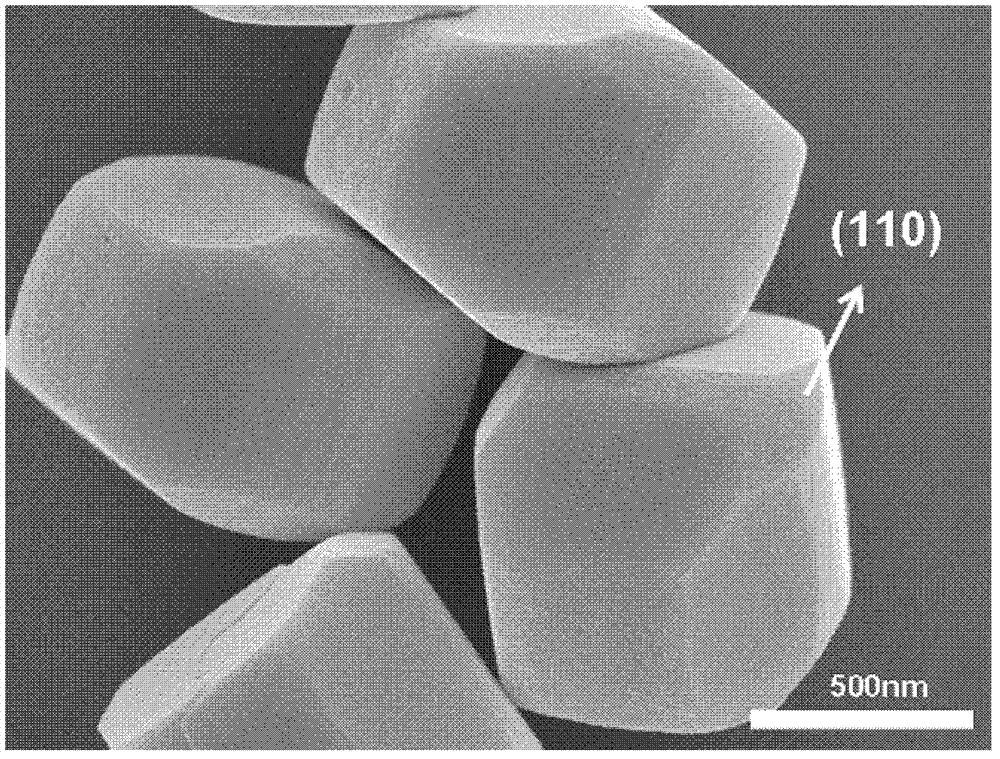

Preparation method of anatase TiO2 monocrystal having high-activity (110) face

An anatase, high-activity technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of no patent report on anatase single crystal, and achieve the goal of inhibiting products from easily crossing or agglomerating, The effect of full utilization of reaction raw materials and strong reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example is used to illustrate the preparation method provided by the present invention.

[0038] (1) Weigh 10 mg of titanium metal powder, add it to the polytetrafluoro reactor liner, add 27ml high-purity water, 0.08ml hydrofluoric acid (aqueous solution with a concentration of 54mol / L) and 1.5 ml of hydrogen peroxide (aqueous solution with a concentration of 30% by weight), and electromagnetically stirred for 10 min to obtain a titanium-containing solution.

[0039] (2) Put the titanium-containing solution prepared in step (1) in a 100 mL autoclave, seal the autoclave, and react at 160° C. for 15 hours.

[0040] (3) After the reaction was completed, the resulting product was washed 8 times with 500 ml of high-purity water, and then washed 3 times with 150 ml of ethanol until its pH value reached 7. The product was dried in an oven for 2 hours.

[0041] (4) Grind the dried product evenly and calcinate at 450°C for 2 hours to obtain anatase TiO with a highly activ...

Embodiment 2

[0044] This example is used to illustrate the preparation method provided by the present invention.

[0045](1) Weigh 10 mg of powder of titanium metal, add it into the polytetrafluoro reactor liner, add 25ml high-purity water, 0.1ml hydrofluoric acid (concentration is the aqueous solution of 56mol / L) and 5ml of hydrogen peroxide (30% by weight aqueous solution), and electromagnetically stirred for 10 minutes to obtain a titanium-containing solution.

[0046] (2) Put the titanium-containing solution prepared in step (1) in a 100 mL autoclave, seal the autoclave, and react at 200° C. for 10 hours.

[0047] (3) After the reaction is completed, the resulting product is washed 5 times with 500 ml of high-purity water, and then 5 times with 200 ml of ethanol until its pH value reaches 7. The product was dried in an oven for 2 hours.

[0048] (4) Grind the dried product evenly and calcinate at 500°C for 3 hours to obtain anatase TiO with a highly active (110) surface 2 single cry...

Embodiment 3

[0051] This example is used to illustrate the preparation method provided by the present invention.

[0052] (1) Weigh 20 mg of titanium metal powder, add it to the polytetrafluoro reactor liner, add 20 ml of high-purity water, 0.5 ml of hydrofluoric acid (aqueous solution with a concentration of 50 mol / L) and 3ml of hydrogen peroxide (30% by weight aqueous solution), and electromagnetically stirred for 10 minutes to obtain a titanium-containing solution.

[0053] (2) Put the titanium-containing solution prepared in step (1) in a 100 mL autoclave, seal the autoclave, and react at 180° C. for 18 hours.

[0054] (3) After the reaction was completed, the resulting product was washed 6 times with 600 ml of high-purity water, and then washed 5 times with 150 ml of ethanol until its pH value reached 7. The product was dried in an oven for 2 hours.

[0055] (4) Grind the dried product evenly, and calcinate it at 600°C for 1 hour to obtain anatase TiO with a highly active (110) surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com