Technology for preparing natural gas from coal-gasification synthetic gas

A natural gas, gas-forming technology, applied in the petroleum industry, gas fuel, fuel, etc., to reduce operating power consumption, improve economy, and reduce solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

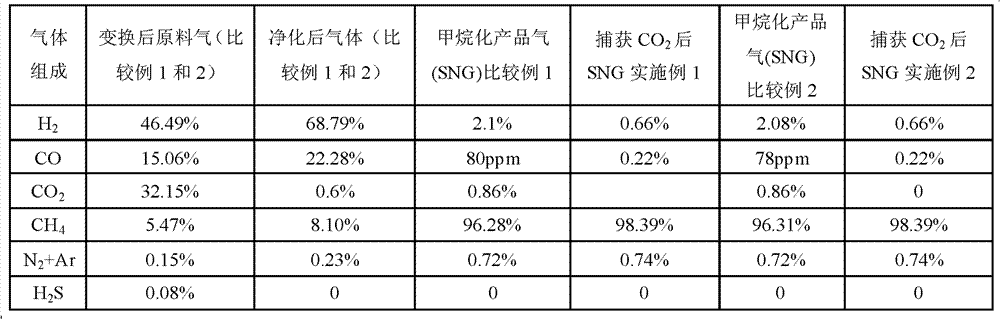

Embodiment 1

[0042] Taking a typical gasifier as an example, pulverized coal reacts with oxygen and water vapor in the gasifier to generate crude gas. The typical composition of the crude gas after removing particles and tar is: 24.77%H 2 , 5.24% CH 4 , 34.13% CO, 11.07% CO 2 , 24.06%H 2 O, 0.08% H 2 S, 0.5% NH 3 , 0.08% Ar, 0.07% N 2 . The crude gas undergoes sulfur-resistant conversion first and then purification, or first purification and then sulfur-resistant conversion, and the NH in the crude gas 3 and H 2 S removed. After conversion and purification treatment, adjust the H in the raw gas 2 The / 3CO ratio is around 1.0, and the composition is: 46.65%H 2 , 15.44% CO, 32.21% CO 2 , 5.52% CH 4 , 0.16%N 2 +Ar; Then the gas enters the methanation unit. The methanation process adopts a four-stage circulating adiabatic fixed-bed reaction process, and a one-stage circulation process. After the gas at the outlet of the first-stage reactor is cooled in multiple stages, part of the ...

Embodiment 2

[0046] Taking a typical gasifier as an example, pulverized coal reacts with oxygen and water vapor in the gasifier to generate crude gas. The typical composition of the crude gas after removing particles and tar is: 24.77%H 2 , 5.24% CH 4 , 34.13% CO, 11.07% CO 2 , 24.06%H 2 O, 0.08% H 2 S, 0.5% NH 3 , 0.08% Ar, 0.07% N 2 . The crude gas undergoes sulfur-resistant conversion first and then purification, or first purification and then sulfur-resistant conversion, and the NH in the crude gas 3 and H 2 S removed. After conversion and purification treatment, adjust the H in the raw gas 2 The / 3CO ratio is around 1.0, and the composition is: 46.65%H 2 , 15.44% CO, 32.21% CO 2 , 5.52% CH 4 , 0.16%N 2 +Ar; then the gas enters the methanation unit. The methanation process adopts a four-stage circulating adiabatic fixed-bed reaction process, and a two-stage circulating process. The gas at the outlet of the first-stage reactor is cooled in multiple stages, and fresh raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com