AM (acrylamide)/NaAA (sodium acrylic acid)/AMPL (N-allyl morpholinium) ternary copolymer oil displacement agent and synthesis method thereof

A terpolymer and terpolymer technology, applied in the direction of drilling compositions, chemical instruments and methods, to achieve the effects of high synthesis yield, easy operation, and high resistance to shear dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the synthesis of terpolymer P (AM / NaAA / AMPL)

[0028] Weigh a certain amount of hydrophobic monomer N-allylmorpholine (AMPL) and alkylphenol polyoxyethylene ether (OP-10) in a 250mL flask, add 50mL of distilled water and stir for 0.5-1h to the solution, transfer to a 250mL three-port in the flask. At room temperature, with the N 2 Add 50mL of distilled water to the three-necked flask of the tube and stirring device, and add a certain amount of acrylamide (AM) and acrylic acid (AA), and stir to dissolve them completely. Use NaOH solution to adjust the pH value of the polymerization system, and then add a certain amount of distilled water to adjust the concentration of the three monomers in the system. Constant temperature in the water bath, and pass N 2 After stirring for 30min, ammonium persulfate ((NH 4 ) 2 S 2 o 8 ) and sodium bisulfite (NaHSO 3). The constant temperature reaction was continued for 8h to obtain a polymer colloid. Cut the polyme...

Embodiment 2

[0029] Embodiment 2: P (AM / NaAA / AMPL) terpolymer structural characterization

[0030] The infrared spectrogram of the ternary polymer P (AM / NaAA / AMPL) synthesized by embodiment 1 is as follows figure 1 Shown: As can be seen from the figure, -NH 2 Stretching vibration peak at 3408cm -1 , the C=O stretching vibration peak is at 1666cm -1 at C-CH 2 -C antisymmetric stretching vibration peak at 2932cm -1 , the stretching vibration peak of C-O-C is at 1182cm -1 and 1120cm -1 , The absorption peak of -COO- is 1557cm -1 .

Embodiment 3

[0031] Embodiment 3: the determination of the optimal synthesis condition of terpolymer P (AM / NaAA / AMPL)

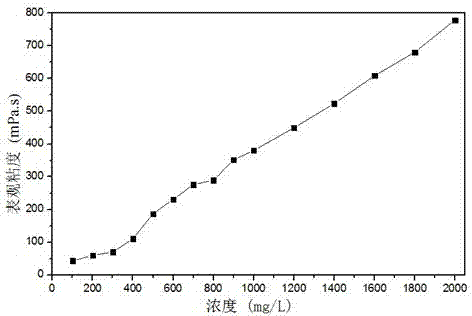

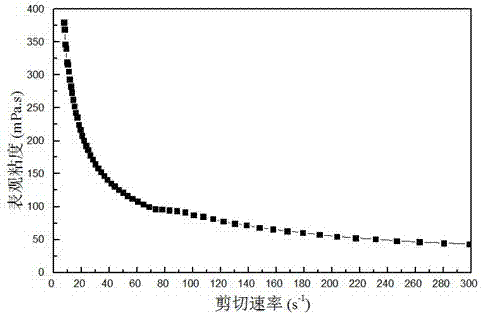

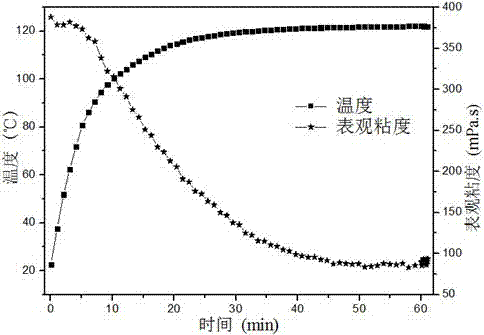

[0032] The main parameters affecting the apparent viscosity of the polymer solution are: initiator dosage, pH value, AMPL dosage, reaction temperature, AM / AA ratio and total monomer concentration. Optimum condition determination method is: the polymkeric substance obtained by embodiment 1 is configured into the polymkeric substance aqueous solution that polymkeric substance concentration is 1000mg / L with distilled water, measures solution apparent viscosity with Brookfield DV-Ⅲ rheometer, selects apparent The formula with higher viscosity is the better formula. The test conditions are: constant shear rate 7.34s -1 , Viscosity measurement temperature 25 ℃.

[0033] 1. Influence of initiator dosage on apparent viscosity of polymer solution

[0034] The present invention uses the redox system of ammonium persulfate-sodium bisulfite as the initiator. In the monomer ratio A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com