Preparation method of composite transparent conductive film of metal nanowires and metallic oxides

A transparent conductive film, metal nanowire technology, applied in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve the problems of poor environmental stability, low adhesion, difficult processing and preparation, etc., to achieve adhesion and Good environmental stability, high surface flatness, and the effect of solving surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the above-mentioned composite layer 200 is a solution processing method such as spin coating, drop coating, doctor blade coating, and printing.

[0028] Specifically, the preparation method of the metal nanowire and metal oxide composite transparent conductive film of the present invention:

[0029] After mixing the metal nanowire solution and the metal oxide solution in different proportions, a composite layer 200 with a thickness of 30-500 nm is prepared on the planar substrate 100 by a solution processing method. The volume mixing ratio of the metal nanowire solution and the metal oxide solution is 1:100-50:1, and the solvent is an organic solvent such as ethanol or isopropanol.

[0030] The above-mentioned planar substrate 100 is rigid or flexible material such as glass, plastic, quartz or semiconductor.

[0031] The concentration of the above metal oxide solution is 1-30mg / ml. Metal oxide materials are TiOx, ZnO, V 2 o 5 、WO 3 or MoO ...

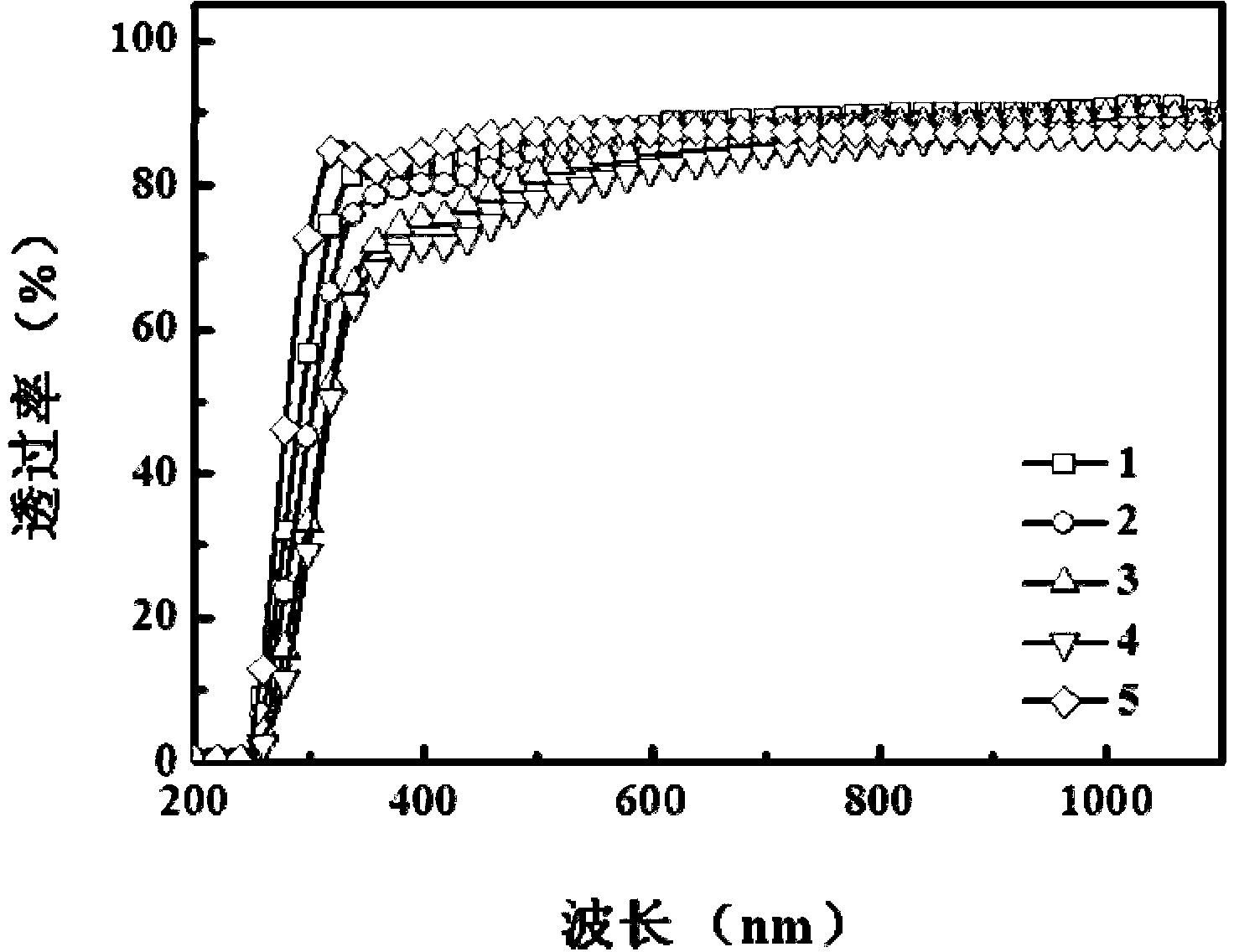

Embodiment 1

[0037] A TiO ethanol solution with a concentration of 2 mg / ml and an AgNW ethanol solution with a concentration of 0.2 mg / ml were mixed at a volume ratio of 1:1, and then metal nanowires and metal nanowires with a thickness of 60 nm were prepared on a planar substrate 100 by solution spin coating. Metal oxide thin film, as composite layer 200. Wherein the planar substrate 100 is a glass substrate; the AgNW has a diameter of 50 nm and a length of 15 μm.

Embodiment 2

[0039]A TiOx ethanol solution with a concentration of 4 mg / ml and an AgNW ethanol solution with a concentration of 0.2 mg / ml were mixed at a volume ratio of 1:1, and then metal nanowires and metal nanowires with a thickness of 100 nm were prepared on a planar substrate 100 by solution spin coating. oxide thin film, as the composite layer 200. Wherein the planar substrate 100 is a glass substrate; the AgNW has a diameter of 50 nm and a length of 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com