Method for preparing meta-position aramid fibers

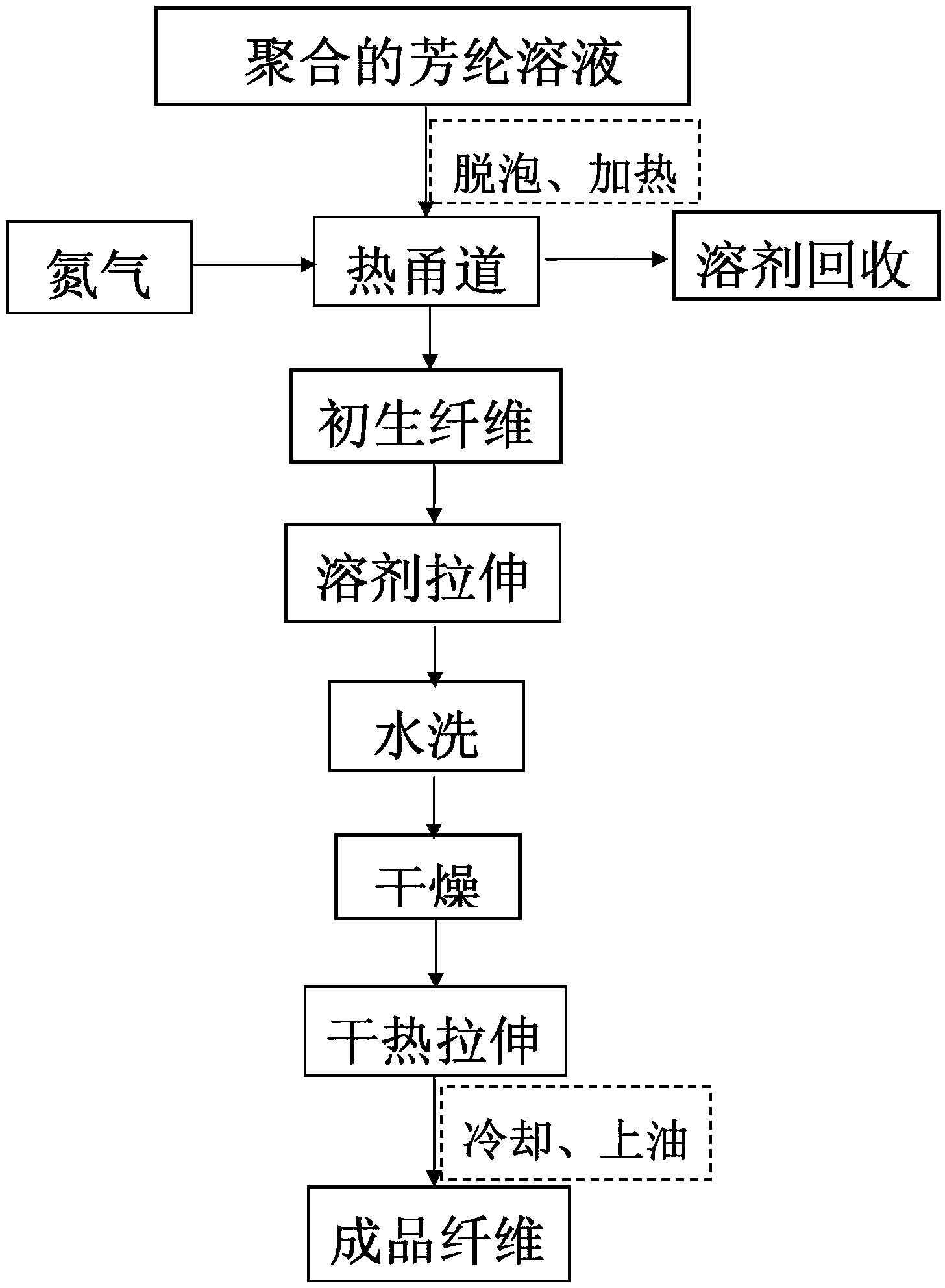

A fiber and poly-m-phenylene isophthalamide technology, which is applied in the field of fiber manufacturing, can solve the problems of high cost, reduced product performance, reduced protection level and the like, and achieves the effects of saving energy and simplifying solvent recovery steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The concentration of polym-phenylene isophthalamide in the polymer spinning solution is 17.5wt%, hydrogen chloride 1.5wt%, and N,N-dimethylacetamide 81wt%. The polym-phenylene isophthalamide spinning solution is heated to 100°C by a heater. The hot air medium in the spinning hot tunnel is hot nitrogen, and the temperature of the hot nitrogen is 200°C. The stretching ratio of the primary fiber nozzle is 1.5 times. The medium of the solvent stretching bath is: 16wt% aqueous solution of N,N-dimethylacetamide, and the fiber solvent stretching ratio is 2 times. The thermal stretching temperature of polym-phenylene isophthalamide fiber is 290°C, and the dry heat stretching ratio is 2 times. The polym-phenylene isophthalamide fiber obtained in this embodiment has a fineness of 2.0 dtex, a tensile strength of 4.5 CN / dtex, and a fiber ash content of 203 ppm.

Embodiment 2

[0023] The concentration of polym-phenylene isophthalamide in the polymer spinning solution is 18.1wt%, hydrogen chloride 1.9wt%, and N,N-dimethylacetamide 80wt%. The polym-phenylene isophthalamide spinning solution is heated to 105°C by a heater. The hot air medium in the spinning tunnel is hot nitrogen, and the temperature of the hot nitrogen is 210°C. The stretching ratio of the primary fiber nozzle is 2 times. The solvent stretching bath medium is: N,N-dimethylacetamide 14wt% aqueous solution, and the fiber solvent stretching ratio is 2 times. The thermal stretching temperature of polym-phenylene isophthalamide fiber is 290°C, and the dry heat stretching ratio is 2.5 times. The polym-phenylene isophthalamide fiber obtained in this embodiment has a fineness of 2.1 dtex, a tensile strength of 4.8 CN / dtex, and a fiber ash content of 230 ppm.

Embodiment 3

[0025] The concentration of polym-phenylene isophthalamide in the polymer spinning solution is 18.5wt%, hydrogen chloride 2.5wt%, and N,N-dimethylacetamide 79wt%. The polym-phenylene isophthalamide spinning solution is heated to 105°C by a heater. The hot air medium in the spinning tunnel is hot nitrogen, and the temperature of the hot nitrogen is 215°C. The stretching ratio of the primary fiber nozzle is 2.5 times. The solvent stretching bath medium is: N,N-dimethylacetamide 12wt% aqueous solution, and the fiber solvent stretching ratio is 2.5 times. The thermal stretching temperature of polym-phenylene isophthalamide fiber is 300°C, and the dry heat stretching ratio is 3 times. The polym-phenylene isophthalamide fiber obtained in this embodiment has a fineness of 2.5 dtex, a tensile strength of 5.0 CN / dtex, and a fiber ash content of 250 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com