Production method of double-screen integrated touch screen with FTO conductive glass

A technology of conductive glass and production method, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of unfavorable ITO material conductivity stability, decrease in conductivity, increase in sheet resistance, etc., and achieve excellent Electrical conductivity, lightest structure, effect of reducing thickness and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

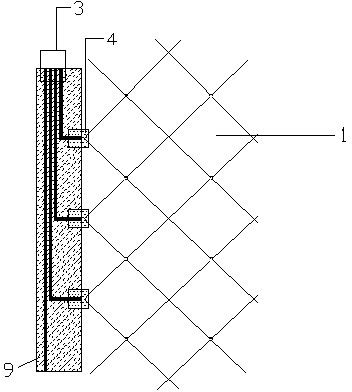

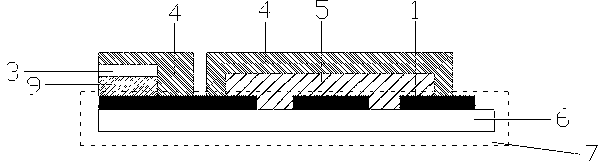

[0047] Reference figure 1 with figure 2 This embodiment is a method for producing a two-screen-in-one touch screen that requires a conductive film to bridge a touch sensor and a cover plate, which specifically includes the following steps:

[0048] Step 1: Select the qualified glass substrate 6 for cleaning and decontamination;

[0049] Step 2: The glass substrate 6 is coated with the FTO conductive thin film 1 to form the FTO conductive glass substrate 7;

[0050] Step 3: Pattern the FTO conductive film according to the preset pattern (the pattern is set as a diamond in this embodiment);

[0051] Step 4: Cut the patterned FTO conductive glass substrate 7 according to the appearance shape of the touch screen;

[0052] Step 5: temper the cut small pieces of FTO conductive glass substrate 7;

[0053] Step 6: First, bridge the two conductive areas separated by a conductive area on the small piece of FTO conductive glass substrate 7 after tempering. The insulating material 5 bridges the two...

Embodiment 2

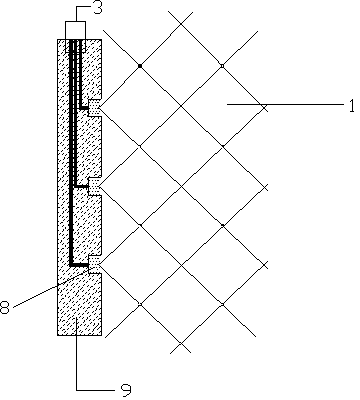

[0058] Reference image 3 with Figure 4 This embodiment is a method for producing a two-screen-in-one touch screen that requires a conductive film to bridge a touch sensor and a cover plate, which specifically includes the following steps:

[0059] Step 1: Select the qualified glass substrate 6 for cleaning and decontamination;

[0060] Step 2: The glass substrate 6 is coated with the FTO conductive thin film 1 to form the FTO conductive glass substrate 7;

[0061] Step 3: Pattern the FTO conductive film according to the preset pattern (the pattern is set as a diamond in this embodiment);

[0062] Step 4: Cut the patterned FTO conductive glass substrate 7 according to the appearance shape of the touch screen;

[0063] Step 5: temper the cut small pieces of FTO conductive glass substrate 7;

[0064] Step 6: First, bridge the two conductive areas separated by a conductive area on the small piece of FTO conductive glass substrate 7 after tempering. The insulating material 5 bridges the two...

Embodiment 3

[0071] Reference Figure 5 with Image 6 This embodiment is a method for producing a two-screen-in-one touch screen that requires a conductive film to bridge a touch sensor and a cover plate, which specifically includes the following steps:

[0072] Step 1: Select the qualified glass substrate 6 for cleaning and decontamination;

[0073] Step 2: The glass substrate 6 is coated with the FTO conductive thin film 1 to form the FTO conductive glass substrate 7;

[0074] Step 3: Pattern the FTO conductive film according to the preset pattern (the pattern is set as a diamond in this embodiment);

[0075] Step 4: Cut the patterned FTO conductive glass substrate 7 according to the appearance shape of the touch screen;

[0076] Step 5: temper the cut small pieces of FTO conductive glass substrate 7;

[0077] Step 6: First, bridge the two conductive areas separated by a conductive area on the small piece of FTO conductive glass substrate 7 after tempering. The insulating material 5 bridges the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com