Preparation method and application of feed

A kind of feed, cockroach technology, applied in the application of the feed, the field of feed preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

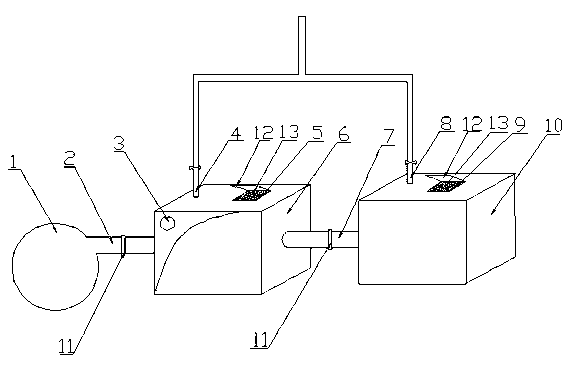

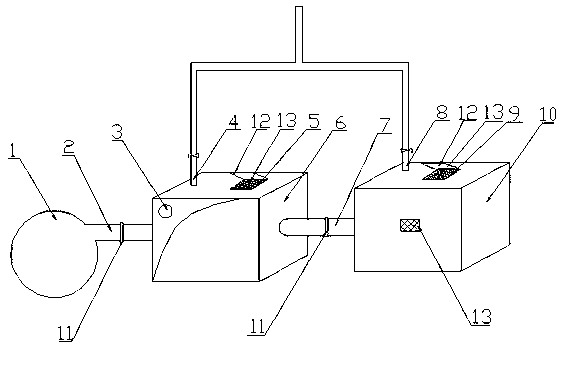

Image

Examples

Embodiment 1

[0063] The preparation method of feed comprises the following steps in embodiment 1:

[0064] (1) Collect kitchen swill;

[0065] (2) Feeding the kitchen swill to cockroaches;

[0066] (3) Catch and kill cockroaches, and perform sterilization and / or virus inactivation treatment; the specific steps are: after capturing and collecting cockroaches, place the cockroaches in a high temperature environment of 100-140°C and steam for 1-120min. Sterilize and virus inactivate while killing cockroaches;

[0067] (4) Dry the cockroaches to obtain feed that can be fed directly.

Embodiment 2

[0069] The preparation method of feed comprises the following steps in embodiment 2:

[0070] (1) Collect kitchen swill;

[0071] (2) Feeding the kitchen swill to cockroaches;

[0072] (3) Catch and kill cockroaches, and perform sterilization and / or virus inactivation treatment; the specific steps are: after capturing and collecting cockroaches, put the cockroaches in a high-temperature environment of 120°C and steam for 60 minutes. This process is to kill cockroaches Simultaneously carry out sterilization and virus inactivation treatment;

[0073] (4) Dry the cockroaches and grind them until their particle size is 20 meshes to obtain cockroach powder. Mix the cockroach powder with the following weight powder components: 200 cockroach powder, 20 corn flour, 20 soybean meal, 8 fish bone powder, Methionine 2, Lysine 3, Sodium Hydrogen Phosphate 3, Soybean Oil 3, Salt 2, Wheat Bran 20, Premix 20, Rapeseed Meal 20, Lactic Acid 3, Multivitamin 3, Tenebrio molitor 6, Calcium Hydro...

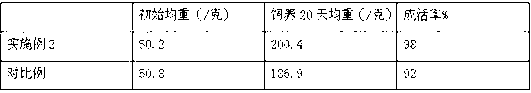

Embodiment 3

[0096] The preparation method of feed comprises the following steps in embodiment 3:

[0097] (1) Collect kitchen swill;

[0098] (3) Catch and kill cockroaches, and perform sterilization and / or virus inactivation treatment; the specific steps are: after capturing and collecting cockroaches, place the cockroaches in a high temperature environment of 100°C and steam for 30 minutes. This process is to kill cockroaches Simultaneously carry out sterilization and virus inactivation treatment;

[0099] (4) Dry the cockroaches and grind them to a particle size of 20 meshes to obtain cockroach powder. Mix the cockroach powder with the following powder components by weight: 80 cockroach powder, 10 corn flour, 10 soybean meal, 5 fish bone meal, Methionine 1, Lysine 1, Sodium hydrogen phosphate 1, Soybean oil 2, Salt 1, Wheat bran 10, Premix 10, Rapeseed meal 5, Lactic acid 1, Multivitamin 1, Tenebrio molitor 1, Calcium hydrogen phosphate 1, Sodium sulfate 1, sodium bicarbonate 1, rice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com