Compound containing carbon nano-tube, hard coating and forming method thereof and hard coating film

A technology of carbon nanotubes and compositions, applied in coatings, optics, instruments, etc., to achieve the effects of improving surface wear resistance, production cost advantages, and improving surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

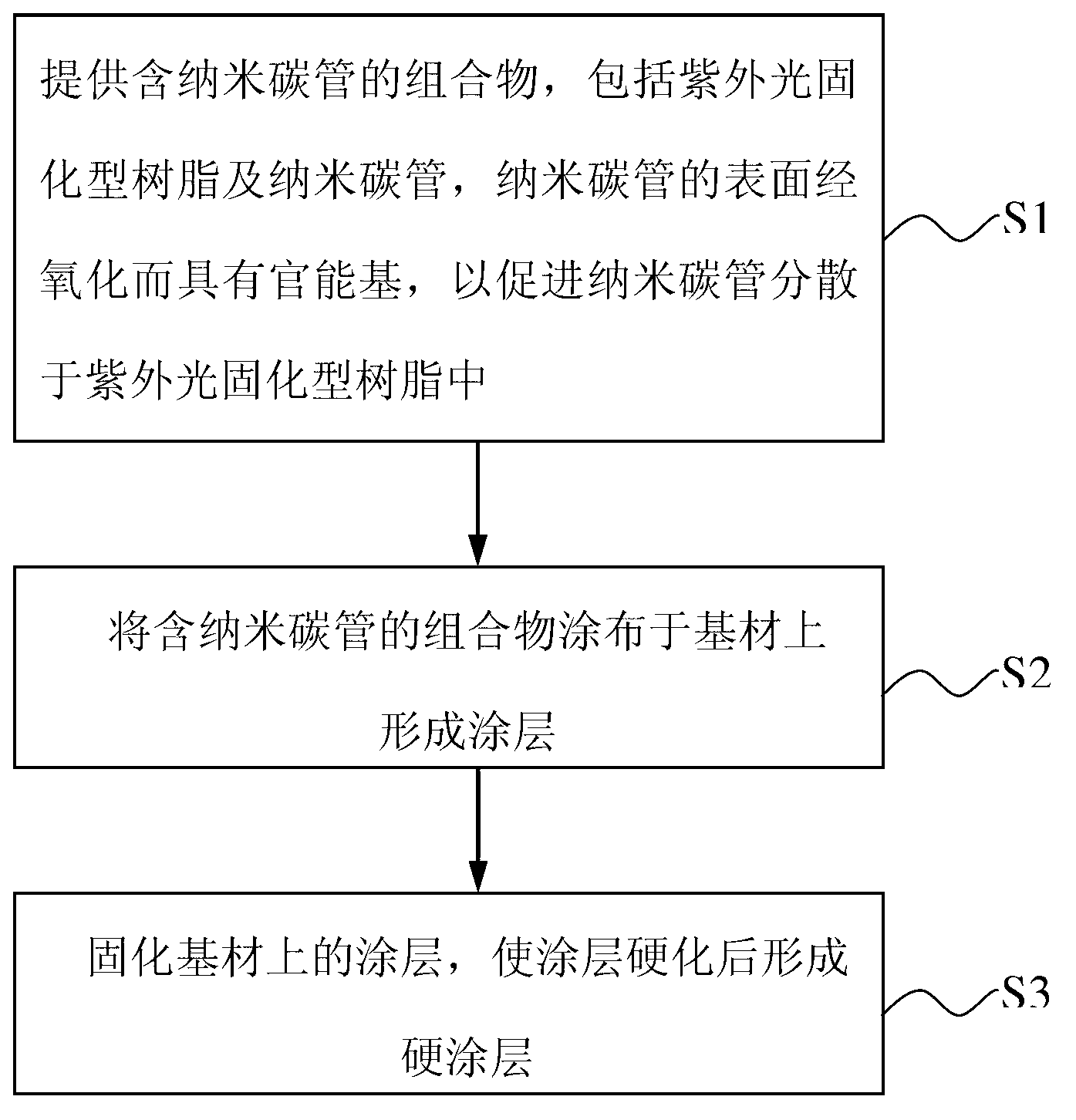

Method used

Image

Examples

Embodiment 1

[0050] First, 0.01g of carbon nanotubes (MWCNT, Gundam Light Co., Ltd.) oxidized by strong acid (sulfuric acid: nitric acid = 1:1) and 9.99g of UV-curable resin (trade name U4690MP1, manufactured by Lida Chemical, solid content About 65%) in a 500ml glass reactor, stirred to make it evenly mixed, and prepared into a mixture containing carbon tube content with a weight of 10g and a carbon nanotube content of 0.1wt% (weight percentage), that is, a mixture containing carbon nanotubes UV-curable resin. The technology of carbon nanotubes being oxidized with a strong acid to form carboxylic acid groups is known, so it will not be repeated here.

[0051] Next, use a coating rod to coat the UV curable resin containing carbon nanotubes on the PMMA with a thickness of 2mm, and dry it in an oven at 80°C for about 2 minutes to remove excess solvent. Then with energy 1000mJ / cm 2 After irradiation with ultraviolet light, a hard coating with a thickness of 5-10 μm can be obtained.

[0052...

Embodiment 2

[0054] 0.05g of carbon nanotubes (MWCNT, Gundam Light Co., Ltd.) oxidized by strong acid (sulfuric acid: nitric acid = 1:1) and 9.95g of UV-curable resin (trade name U4690MP1, manufactured by Lida Chemical Industry Co., Ltd., with a solid content of about 65%) was stirred in a 500ml glass reactor to make it evenly mixed, and prepared into a carbon nanotube-containing mixture with a weight of 10g and a carbon nanotube content of 0.5wt%, that is, an ultraviolet curable resin containing carbon nanotubes.

[0055] Next, use a coating rod to coat the UV curable resin containing carbon nanotubes on the PMMA with a thickness of 2mm, and dry it in an oven at 80°C for about 2 minutes to remove excess solvent. Then with energy 1000mJ / cm 2 After irradiation with ultraviolet light, a hard coating with a thickness of 5-10 μm can be obtained.

[0056] Among them, please refer to Table 1 for the property evaluation results of the PMMA substrate (that is, the hard coating film) formed with the...

Embodiment 3

[0058] 0.1g of carbon nanotubes (MWCNT, Gundam Light Co., Ltd.) oxidized by strong acid (sulfuric acid: nitric acid = 1:1) and 9.90g of UV-curable resin (trade name U4690MP1, manufactured by Lida Chemical Industry Co., Ltd., with a solid content of about 65%) was stirred in a 500ml glass reactor to make it evenly mixed, and prepared into a carbon nanotube-containing mixture with a weight of 10g and a carbon nanotube content of 1.0wt%, that is, a carbon nanotube-containing UV-curable resin.

[0059] Next, use a coating rod to coat the UV curable resin containing carbon nanotubes on the PMMA with a thickness of 2mm, and dry it in an oven at 80°C for about 2 minutes to remove excess solvent. Then with energy 1000mJ / cm 2 After irradiation with ultraviolet light, a hard coating with a thickness of 5-10 μm can be obtained.

[0060] Among them, please refer to Table 1 for the property evaluation results of the PMMA substrate (that is, the hard coating film) formed with the above har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com