Method for producing organic fertilizer by processing animal culture wastes through efficient composite biological probiotics

A livestock and poultry breeding and organic fertilizer technology, which is applied in the preparation of organic fertilizers, bio-organic part treatment, organic fertilizers, etc., can solve problems such as the decline of soil natural fertility and the imbalance of grain growth capacity, and achieve simple production processes and no pollution in the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0060] ①Take 100 kg of waste such as chicken farm and pig farm waste and feces as raw materials;

[0061] ②Take 1 kg of secondary strains cultivated by high-efficiency compound biological probiotics and mix them evenly with 10 kg of corn stalk powder as bacterial auxiliary materials;

[0062]③Mix 100 kg of pig manure and other waste with 5 kg of bacterial auxiliary materials evenly as raw materials for organic fertilizer fermentation, and control the water content at 40-65%;

[0063] ④ ferment the organic fertilizer fermentation raw materials in the fermentation equipment to produce organic fertilizer;

[0064] ⑤ Post-treatment drying to ensure that the effective number of viable bacteria (cfu) of the organic fertilizer is 0.5 billion / g; organic matter (on a dry basis) 40%; moisture 25%; pH value 7.0; fecal coliform count 50 / g (mL ); Ascaris egg mortality rate is 95%.

Embodiment 3

[0066] ①Take 100 kg of waste such as chicken farm and pig farm waste and feces as raw materials;

[0067] ②Take 1 kg of secondary strains cultivated by high-efficiency compound biological probiotics and mix them evenly with 10 kg of corn stalk powder as bacterial auxiliary materials;

[0068] ③Mix 100 kg of pig manure and other waste with 1 kg of bacterial auxiliary materials evenly as raw materials for organic fertilizer fermentation, and control the water content at 40-65%;

[0069] ④ ferment the organic fertilizer fermentation raw materials in the fermentation equipment to produce organic fertilizer;

[0070] ⑤After drying, ensure the effective number of viable bacteria (cfu) of organic fertilizer, 0.1 billion / g; organic matter (on a dry basis) 25%; moisture 40% ≤; pH value 7.0; fecal coliform count, 140 / g g (mL); Ascaris egg mortality rate is 75%.

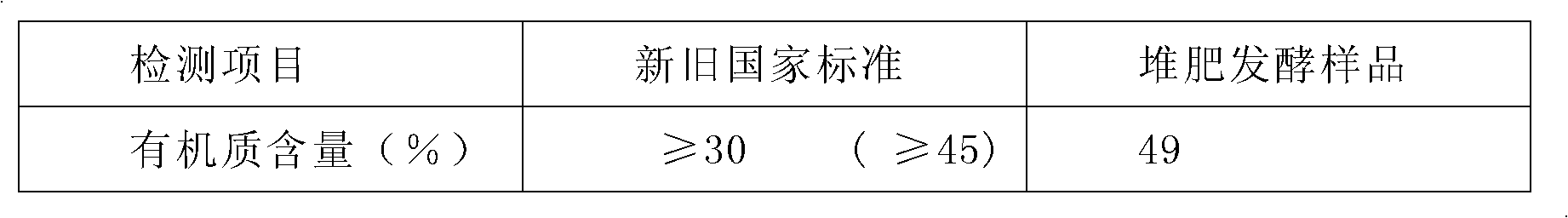

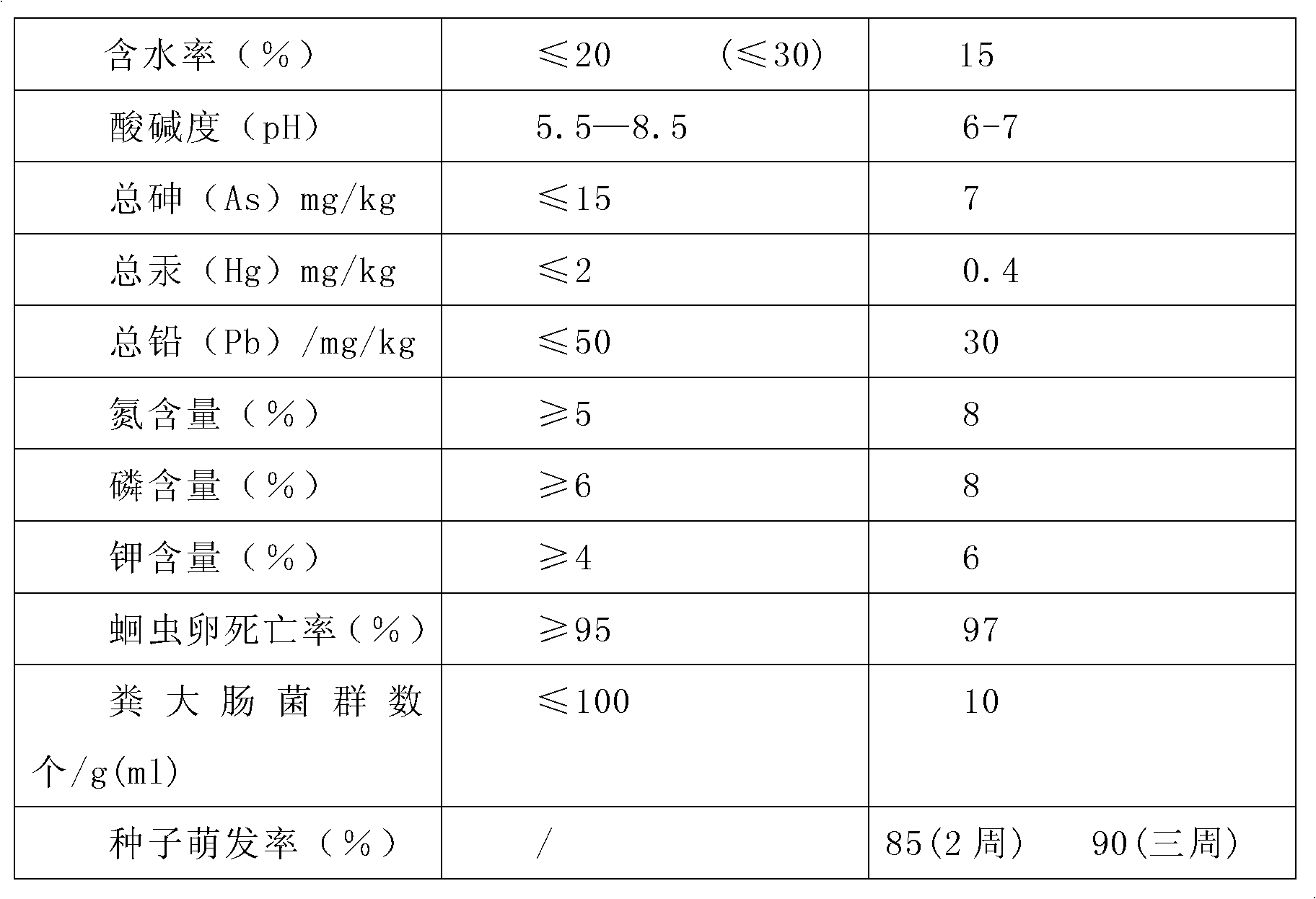

[0071] 2. Organic fertilizer testing

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com