Cold state integral repairing material with high adhesiveness for wall of steel ladle

A technology of adhesion and repairing material, applied in the field of refractory unshaped refractory products, can solve the problems of easy falling off, easy to slide down, poor adhesion performance, etc., and achieve obvious economic benefits, increase safety, and good adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

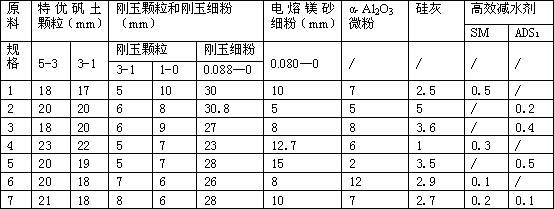

[0029] (1) Crushing and crushing of raw materials: Procure raw materials according to the technical requirements of the raw materials used in the production of the present invention. Among them, the main raw materials, super-high-quality bauxite and fused magnesia, require good sintering, which is specifically reflected in the body density and water absorption. . The high-quality bauxite is processed into 5~3mm and 3~1mm pellets by crushing and screening equipment and sent to the silo, and the fused magnesia is processed by crushing and screening equipment into 180 mesh (0.080-0mm) fine powder and sent to the feed bin. Silo, corundum granules and fines, α-Al 2 o 3 Micropowder, silica fume and admixtures are purchased in the market according to requirements.

[0030] (2) Weighing: according to the production process of the present invention, the proportion of ingredients is 35-45% for super-quality bauxite particles, 35-45% for corundum particles and fine powder, 5-15% for fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com