Strong sealing device of hydraulic chuck for gas pumping rig

A hydraulic chuck and gas extraction technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of high-pressure oil leakage, easy wear, affecting normal and safe use, etc., to reduce friction heat, contact surface The effect of automatic wear compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

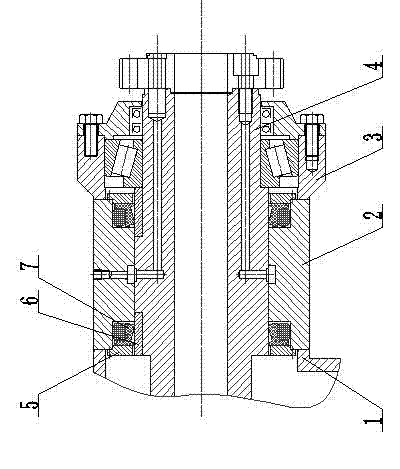

[0010] figure 1 As shown, a strong sealing device for a hydraulic chuck oil distribution sleeve of a gas extraction drilling rig includes a body 1, a cylinder body 2, an outer interface 3, an inner cylinder 4, a gland 5, a wear ring 6 and a TB3 car seal 7. The body 1, the cylinder body 2 are connected with the external interface 3 in sequence, one end of the inner cylinder 4 is connected with the inside of the body 1 and the large gear, and the other end extends out of the external interface 3 to connect the chuck: both ends of the cylinder body 2 are equipped with TB3 car seals 7. The wear-resistant ring 6 and the gland 5, the TB3 car's seal 7 is sealed and pressed between the cylinder body 2 and the inner cylinder 4 through the gland 5, and the outer circular wall of the TB3 car's seal 7 is sealed to the inner wall of the cylinder body 2, TB3 Che's seal 7 inner circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com