Method for synthesizing high-molecular-weight aliphatic polycarbonate

A polycarbonate and high molecular weight technology, applied in the field of high molecular weight aliphatic polycarbonate, can solve the problems of low raw material utilization rate, harsh reaction conditions, DMC loss, etc., achieve low production cost, less usage, and reduce equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

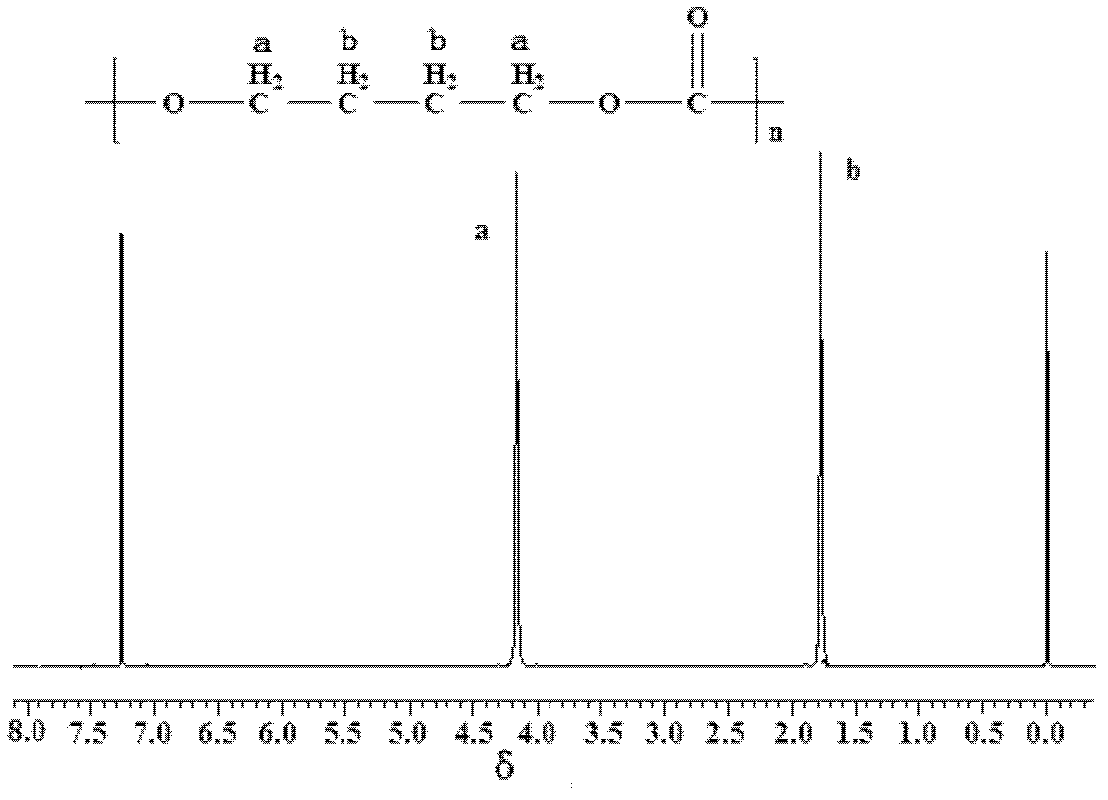

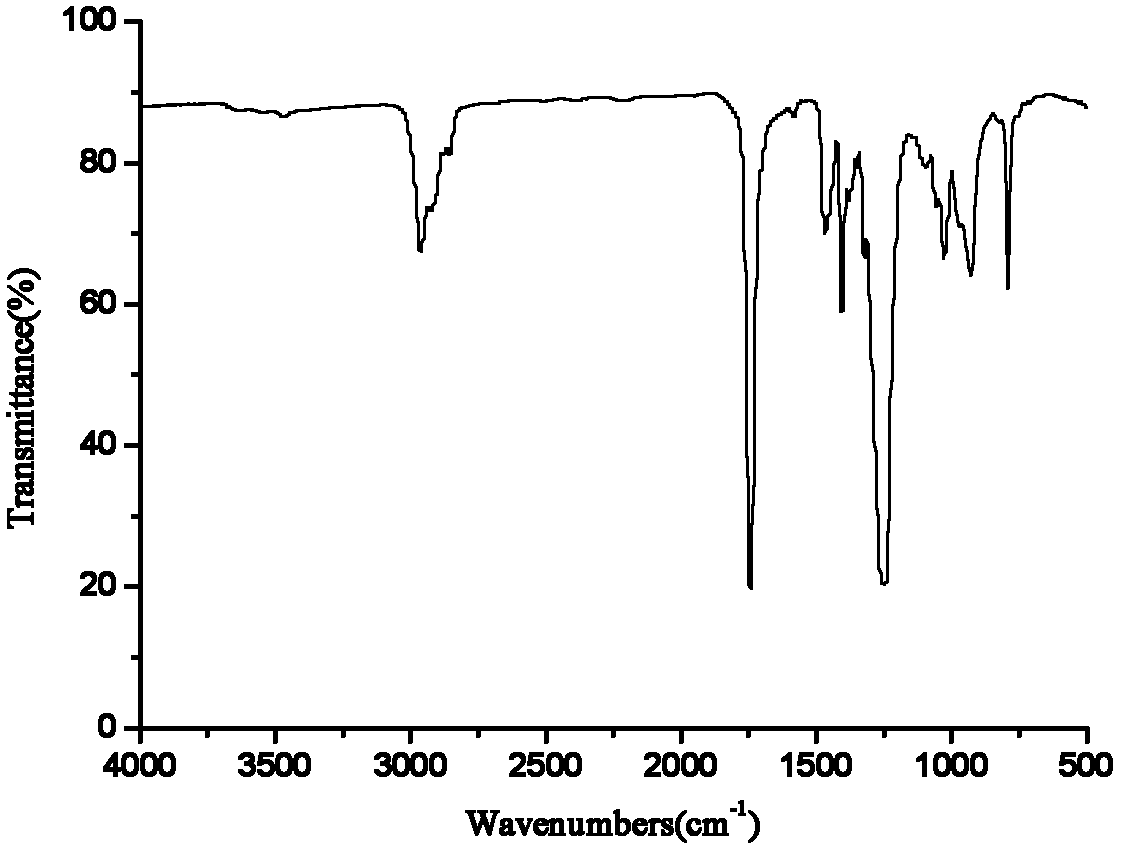

[0033] Under normal pressure, add 118g 1,4-butanediol, 215g diphenyl carbonate, and 0.1g zinc sulfate into a reactor equipped with heating and stirring system, temperature measurement system and fractionation system, and stir under nitrogen atmosphere. The temperature was gradually raised to 170°C, the by-product phenol was fractionally distilled out in time, and the reaction was refluxed for 2 hours until the by-product phenol was no longer distilled, and 0.001 g of stabilizer antioxidant 1010 was added. Then, the pressure of the system was gradually reduced to 1000Pa. After a certain time of reaction, the reaction temperature of the system was gradually increased to 190℃, and the pressure of the system was reduced to 100Pa. The polycondensation was carried out for 5h. The milky white solid was finally obtained as aliphatic polycarbonate with number average molecular weight. It is 62900g / mol and the intrinsic viscosity is 1.11dl / g. The aliphatic polycarbonate 1 The H-NMR spect...

Embodiment 2

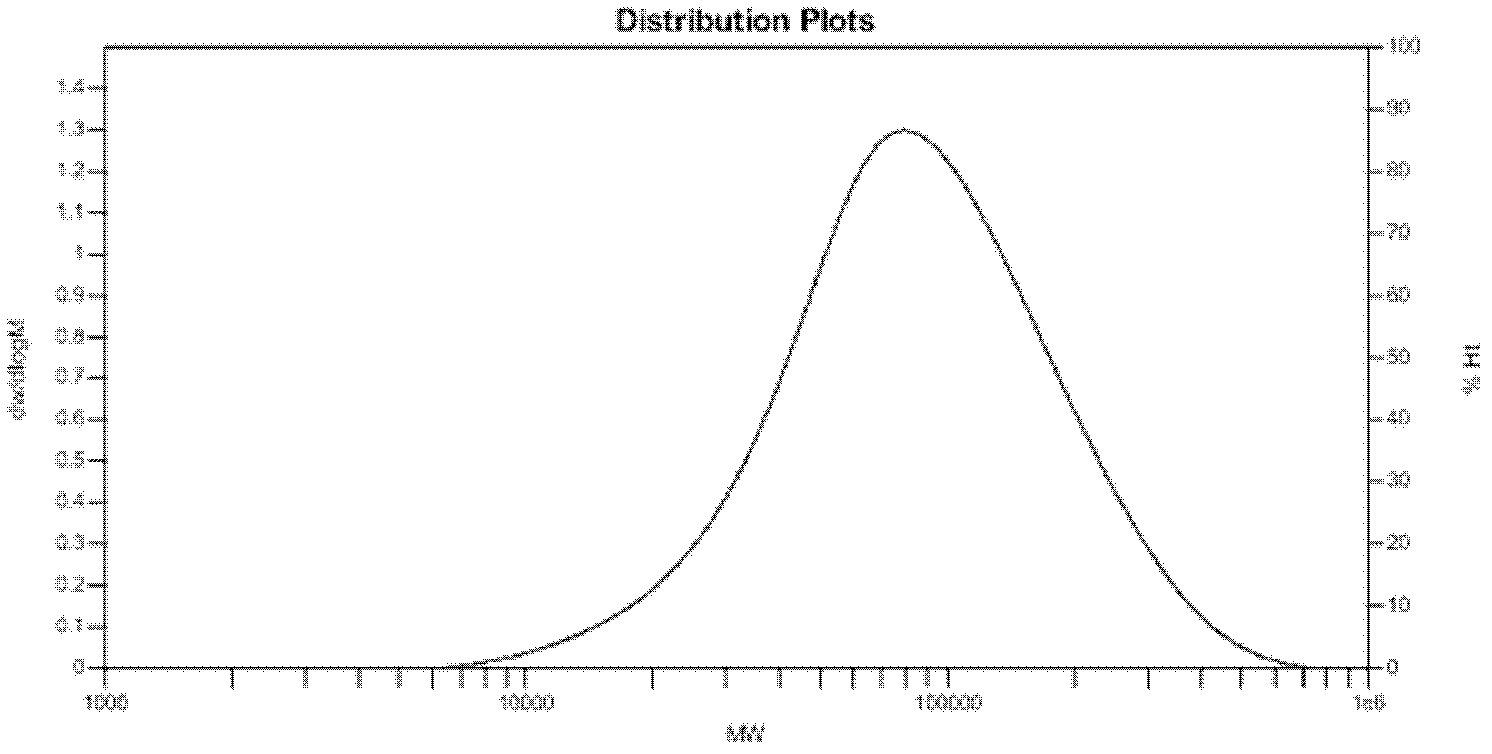

[0035] Under normal pressure conditions, 130g 1,4-butanediol, 215g diphenyl carbonate, and 1.05g zinc chloride were added to a reactor equipped with a heating and stirring system, a temperature measurement system, and a fractionation system. Under a nitrogen atmosphere Stir and gradually raise the temperature to 200°C, fractionate the by-product phenol in time, reflux for 5 hours, until the by-product phenol no longer distills, add 0.001g stabilizer antioxidant 1010. Then, the pressure of the system was gradually reduced to 700Pa. After a certain time of reaction, the reaction temperature of the system was gradually increased to 210°C, and the pressure of the system was reduced to 30Pa. The polycondensation was carried out for 10 hours. The white solid was finally obtained as aliphatic polycarbonate with number average molecular weight. It is 209200g / mol, and the intrinsic viscosity is 1.89dl / g.

Embodiment 3

[0037] Under normal pressure conditions, 150g of 1,4-butanediol, 215g of diphenyl carbonate, and 0.5g of zinc stearate were added to a reactor equipped with a heating and stirring system, a temperature measurement system, and a fractionation system. In a nitrogen atmosphere Under stirring and gradually raising the temperature to 140°C, the by-product phenol was fractionally distilled in time, and the by-product phenol was refluxed for 6 hours until the by-product phenol was no longer distilled, and 0.001 g of stabilizer antioxidant 1010 was added. Then, the pressure of the system was gradually reduced to 2000Pa. After a certain time of reaction, the reaction temperature of the system was gradually increased to 210℃, and the pressure of the system was reduced to 30Pa. The polycondensation was carried out for 6h. The milky white solid was finally obtained as polycarbonate with a number average molecular weight of 113500g. / mol, the intrinsic viscosity is 1.54dl / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com