Nalmefene hydrochloride compound and preparation method thereof

A technology of nalmefene and compound, which is applied in the field of nalmefene hydrochloride compound and its preparation, can solve problems such as toxicity, and achieve the effects of low cost, simplified quality inspection process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

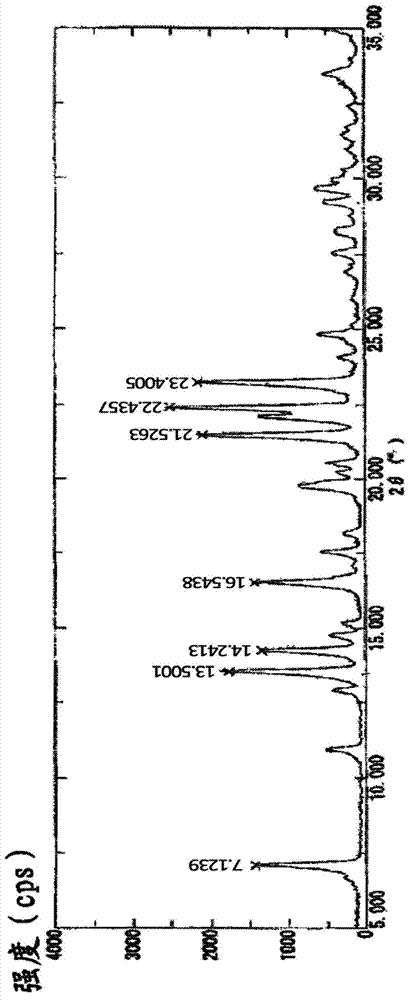

[0024] Add 100.0g of nalmefene hydrochloride (HPLC content 95.16%) and 200.0ml of mixed solvent (ether: acetone: water = 4:1:1) into the three-necked flask, keep at 20-30°C, stir to dissolve nalmefene hydrochloride, Get nalmefene hydrochloride solution; add activated carbon, decolorize for 10-20 minutes, filter, wash the filter cake with a mixed solvent (ether: acetone: water = 4:1:1), collect the filtrate; naturally cool the filtrate to room temperature (15-25 ℃), so that the crystals were fully separated; the crystals were filtered with suction, and the filter cake was washed with water and dried to obtain 94.2 g of nalmefene hydrochloride. The HPLC analysis results are shown in Table 1. Powder diffraction pattern and TG-DTA differential thermal analysis see figure 1 and figure 2 .

Embodiment 2

[0026] Add 100.0g of nalmefene hydrochloride (HPLC content 95.16%) and 300.0ml of mixed solvent (ether: acetone: water = 3:1:1) into the three-necked flask, keep at 20-30°C, stir to dissolve nalmefene hydrochloride, Get nalmefene hydrochloride solution; add activated carbon, decolorize for 10-20 minutes, filter, wash the filter cake with a mixed solvent (ether: acetone: water = 3:1:1), collect the filtrate; naturally cool the filtrate to room temperature (15-25 ℃), so that the crystals were fully separated; the crystals were filtered with suction, and the filter cake was washed with water and dried to obtain 90.9 g of nalmefene hydrochloride. The HPLC analysis results are shown in Table 1. Powder diffraction pattern and TG-DTA differential thermal analysis see figure 1 and figure 2 .

Embodiment 3

[0028] Add 100.0g of nalmefene hydrochloride (HPLC content 95.16%) and 250.0ml of mixed solvent (ether: acetone: water = 5:1:1) into the three-necked flask, keep at 20-30°C, stir to dissolve nalmefene hydrochloride, Get nalmefene hydrochloride solution; add activated carbon, decolorize for 10-20 minutes, filter, wash the filter cake with a mixed solvent (ether: acetone: water = 5:1:1), collect the filtrate; naturally cool the filtrate to room temperature (15-25 ℃), so that the crystals were fully separated; the crystals were filtered with suction, and the filter cake was washed with water and dried to obtain 93.3 g of nalmefene hydrochloride. The HPLC analysis results are shown in Table 1. Powder diffraction pattern and TG-DTA differential thermal analysis see figure 1 and figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com