Method for extracting high purity 1-deoxynojirimycin

A deoxynojirimycin and extraction method technology, which is applied in the field of extraction of high-purity 1-deoxynojirimycin, can solve the problems of low extraction rate and purity of the product, and high toxicity of the product, so as to improve the extraction rate and product quality and safety , the effect of high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

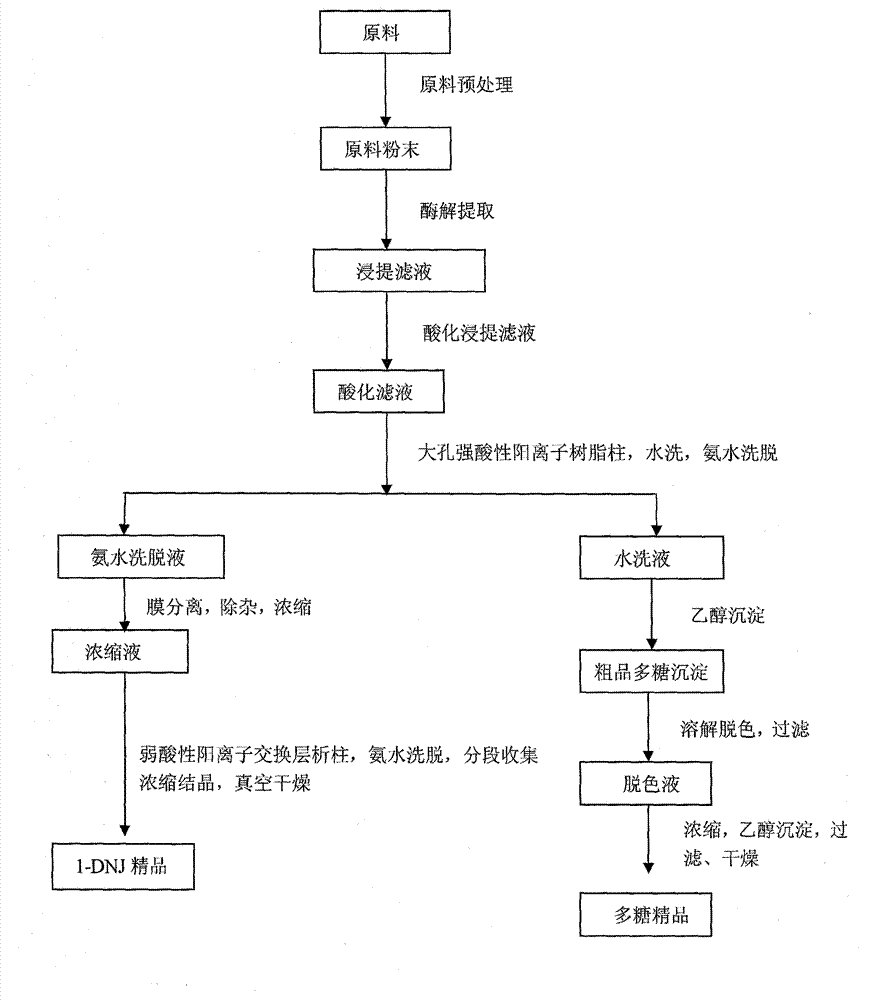

Method used

Image

Examples

Embodiment 1

[0048] A method for extracting high-purity 1-deoxynojirimycin, comprising the steps of:

[0049] 1. Raw material pretreatment: Take the mulberry branches, dry them, crush them, pass through a 40-mesh sieve, and obtain the raw material powder for extraction;

[0050] 2. Enzymatic extraction:

[0051] (1) Add 8 times the weight of water to the raw material powder, heat up to 47±2°C, add 0.5% of the combined enzyme of the raw material powder weight, keep warm, enzymolysis and leaching for 8 hours, and then obtain the filter residue and filtrate through centrifugal filtration; The composition and weight ratio of the combined enzymes are cellulase: dextranase: pectinase=3: 2: 1;

[0052] (2) Repeat enzymatic hydrolysis and leaching of the filter residue, the operation is the same as step (1), and filter;

[0053] (3) merging step (1) and step (2) twice leaching filtrate;

[0054] 3. The leaching filtrate is centrifuged to remove the slag with a centrifuge, and then the pH value ...

Embodiment 2

[0061] A method for extracting high-purity 1-deoxynojirimycin, comprising the steps of:

[0062] 1. Raw material pretreatment: take mulberry leaves, dry them, crush them, pass through a 40-mesh sieve, and obtain the raw material powder for extraction;

[0063] 2. Enzymatic hydrolysis and extraction: add 12 times the weight of water to the raw material powder, after heating up to 58±2°C, add 0.8% of the combined enzyme of the raw material powder weight, keep warm, enzymatic hydrolysis and extraction for 10 hours, and then centrifuge to obtain the leaching Extract the filtrate; the composition and weight ratio of the combined enzymes are cellulase: dextranase: pectinase=5: 4: 1;

[0064] 3. The leaching filtrate is centrifuged to remove the slag with a centrifuge, and then the pH is adjusted to 4-5 with acid;

[0065] 4. Put the acidified filtrate on a strongly acidic cationic resin column, rinse with purified water 4 times the volume of the resin, collect the washing liquid, a...

Embodiment 3

[0070] A method for extracting high-purity 1-deoxynojirimycin, comprising the steps of:

[0071] 1. Raw material pretreatment: Take sericulture waste (silkworm excrement) and grind it after drying, and pass through a 30-mesh sieve to obtain the raw material powder for extraction;

[0072] 2. Enzymatic extraction:

[0073] (1) Add 10 times the weight of water to the raw material powder, heat up to 55±2° C., add 0.5% of the combined enzyme of the raw material powder weight, keep warm, enzymolysis and leaching for 12 hours, and then centrifuge to obtain the leaching filtrate; The composition and weight ratio of the combined enzymes are cellulase: dextranase: pectinase=4: 3: 1;

[0074] (2) Repeat enzymatic hydrolysis and leaching of the filter residue, the operation is the same as step (1), and filter;

[0075] (3) merging step (1) and step (2) twice leaching filtrate;

[0076] 3. The leaching filtrate is centrifuged to remove the slag with a centrifuge, and then the pH is adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com