Production method for copper-titanium composite tube

A production method and composite pipe technology, which is applied in the production field of copper-titanium composite pipe, can solve the problems of poor product quality, easy relative sliding, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

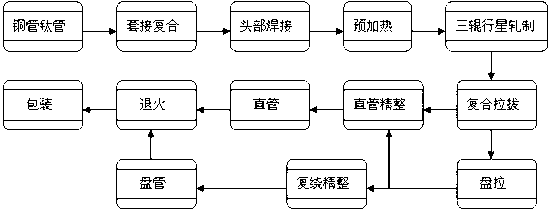

[0027] Such as figure 1 As shown, the production method of the copper-titanium composite pipe of the present embodiment comprises the following steps:

[0028] (1) Mill the copper tube billet produced by horizontal continuous casting to remove the oxide layer on the surface.

[0029] ⑵Use a steel brush to clean the surface to be compounded of the two materials, so that a new rough raised hardened layer is formed on the surface.

[0030] (3) Put the titanium tube inside the copper tube, and it is required to minimize the difference between the outer diameter of the titanium and titanium alloy tube and the inner diameter of the copper tube, because the mandrel head is placed inside the inner tube, the larger the gap between the two materials, the outer The more uneven the force on the tube.

[0031] ⑷ The two layers of material on the head are welded to form a composite tube blank. When welding, silver-based brazing material BAg72Cu is selected as the welding material of the c...

Embodiment 2

[0037] Such as figure 1 As shown, the production method of the copper-titanium composite pipe of the present embodiment comprises the following steps:

[0038] (1) Mill the copper tube billet produced by horizontal continuous casting to remove the oxide layer on the surface.

[0039] ⑵Use a steel brush to clean the surface to be compounded of the two materials, so that a new rough raised hardened layer is formed on the surface.

[0040] (3) Put the titanium tube inside the copper tube, and it is required to minimize the difference between the outer diameter of the titanium and titanium alloy tube and the inner diameter of the copper tube, because the mandrel head is placed inside the inner tube, the larger the gap between the two materials, the outer The more uneven the force on the tube.

[0041] ⑷ The two layers of material on the head are welded to form a composite tube blank. When welding, silver-based brazing material BAg72Cu is selected as the welding material of the c...

Embodiment 3

[0047] Such as figure 1 As shown, the production method of the copper-titanium composite pipe of the present embodiment comprises the following steps:

[0048] (1) Mill the copper tube billet produced by horizontal continuous casting to remove the oxide layer on the surface.

[0049] ⑵Use a steel brush to clean the surface to be compounded of the two materials, so that a new rough raised hardened layer is formed on the surface.

[0050] (3) Put the titanium tube inside the copper tube, and it is required to minimize the difference between the outer diameter of the titanium and titanium alloy tube and the inner diameter of the copper tube, because the mandrel head is placed inside the inner tube, the larger the gap between the two materials, the outer The more uneven the force on the tube.

[0051] ⑷ The two layers of material on the head are welded to form a composite tube blank. When welding, silver-based brazing material BAg72Cu is selected as the welding material of the cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com