Hierarchy MoS2/Cu2S composite material and preparation method thereof

A hierarchical structure, composite material technology, applied in catalyst activation/preparation, chemical instruments and methods, nanotechnology for materials and surface science, etc. Specific surface area, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

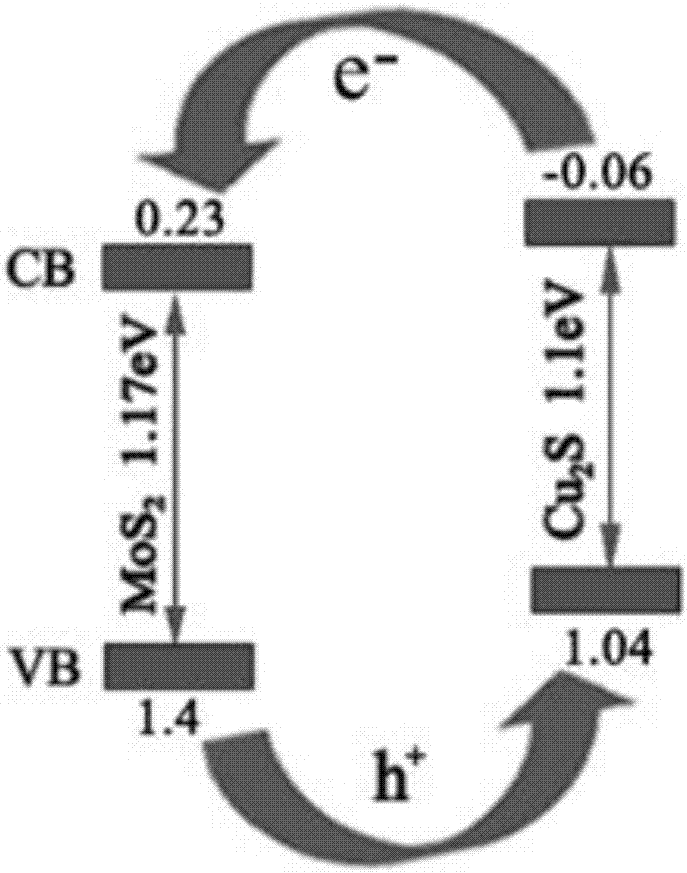

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A Hierarchical MoS 2 / Cu 2 S composite material, its preparation method comprises the steps:

[0039] Add 0.4g of sodium molybdate, 0.4g of thioacetamide, and 0.04g of copper sulfate pentahydrate into a mixed solution of 20mL of ethylenediamine, 40mL of water and 20mL of ethanol, stir and mix evenly (the stirring temperature is 25°C, and the stirring rate is 700r / min), then put the resulting mixture in a reaction kettle, seal it and heat it to 200°C for constant temperature crystallization reaction (hydrothermal reaction). After reacting for 24 hours, carry out suction filtration, washing, and then dry at 60°C to score hierarchical structure MoS 2 / Cu 2 S composites.

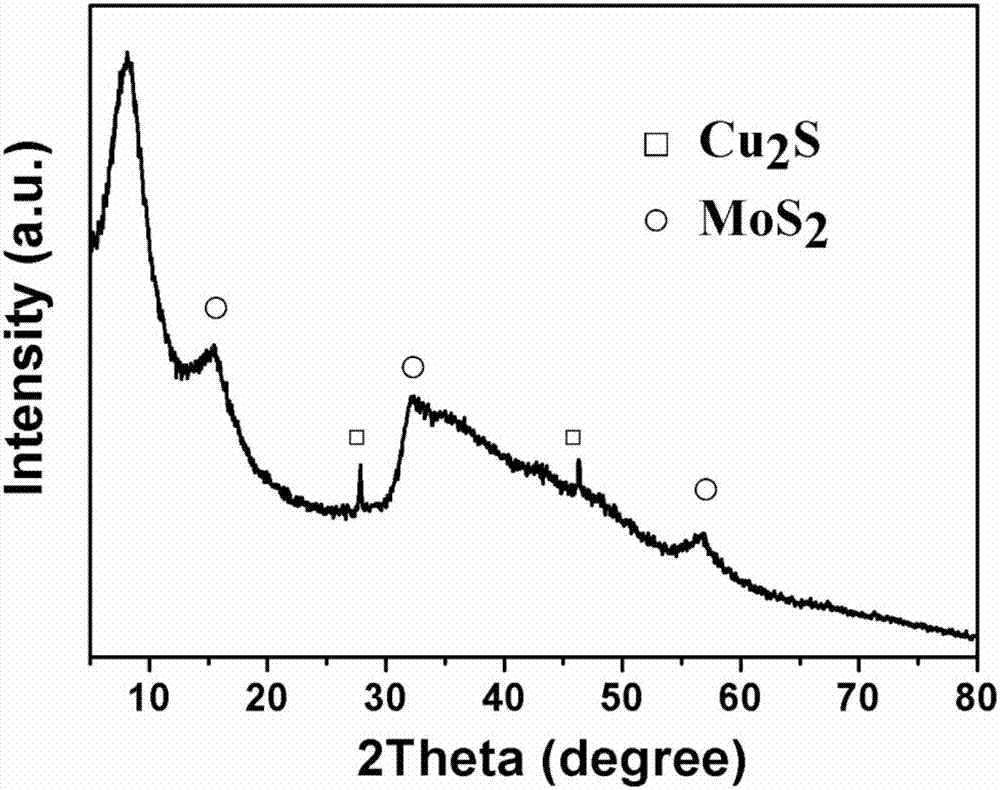

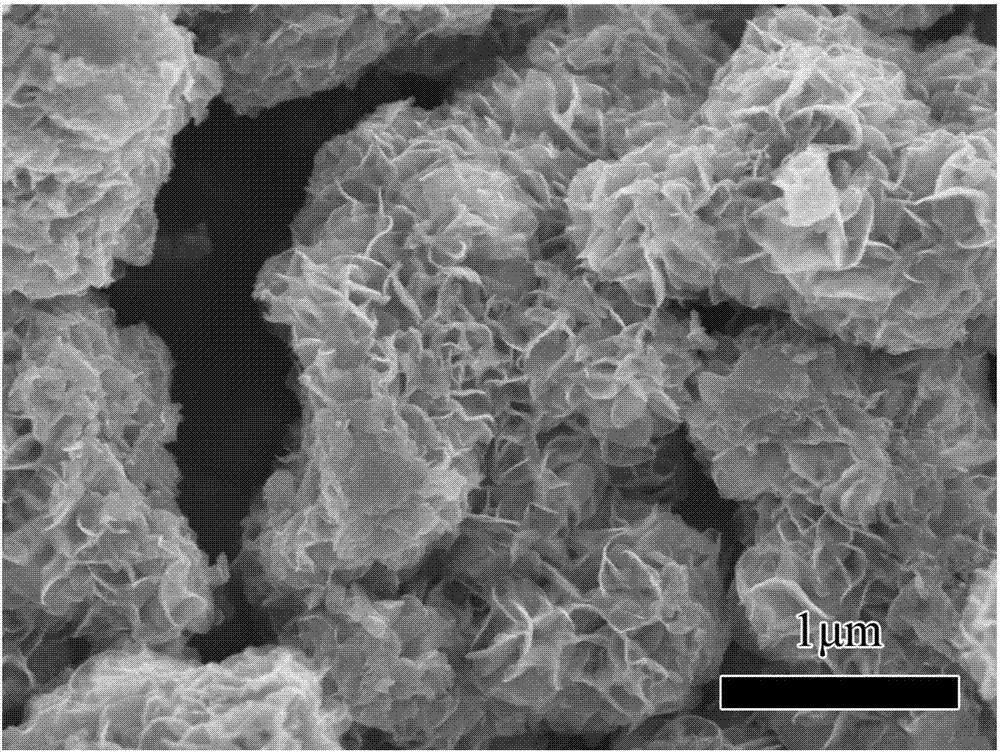

[0040] The product obtained in this example is determined to be the same as the MoS of hexagonal crystal form through X-ray diffraction analysis. 2 and Cu 2 The S phase matches, and the crystallinity is good, and its X-ray diffraction pattern is shown in figure 2 . Scanning electron microscopy re...

Embodiment 2

[0044] A Hierarchical MoS 2 / Cu 2 S composite material, its preparation method comprises the steps:

[0045] Add 0.4g of sodium molybdate, 0.8g of thioacetamide, and 0.08g of copper sulfate pentahydrate into a mixed solution of 20mL of ethylenediamine, 40mL of water and 20mL of ethanol, stir and mix evenly (the stirring temperature is 25°C, and the stirring rate is 700r / min), then put the resulting mixture in a reaction kettle, seal it and heat it to 220°C for constant temperature crystallization reaction (hydrothermal reaction), after 48 hours of reaction, carry out suction filtration, washing, and then dry at 60°C to score hierarchical structure MoS 2 / Cu 2 S composites.

[0046] The product obtained in this example is determined by X-ray diffraction analysis to be consistent with hexagonal MoS 2 and Cu 2 The S phase matches, and the crystallinity is good, and its X-ray diffraction pattern is shown in Figure 6 . Scanning electron microscopy results showed that ( F...

Embodiment 3

[0048] A Hierarchical MoS 2 / Cu 2 S composite material, its preparation method comprises the steps:

[0049] Add 0.4g of sodium molybdate, 0.4g of thioacetamide, and 0.08g of copper sulfate pentahydrate into a mixed solution of 40mL of ethylenediamine, 20mL of water and 20mL of ethanol, stir and mix evenly (the stirring temperature is 25°C, and the stirring rate is 700r / min) to obtain the solution, then put the obtained solution into the reaction kettle, seal it and heat it to 180°C for constant temperature crystallization reaction, after 24 hours of reaction, perform suction filtration, washing, and then dry at 60°C to obtain a hierarchical structure The hexagonal MoS 2 / Cu 2 S composites.

[0050] The product obtained in the steps of this example is determined to be consistent with hexagonal MoS through X-ray diffraction analysis. 2 and Cu 2 The S phase matches, and the crystallinity is good, and its X-ray diffraction pattern is shown in Figure 8 . Scanning electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com