Double phosphorescent coloring agent common adulterate white light organic electroluminescent device and method for fabricating the same

A technology for electroluminescent devices and phosphorescent dyes, which is applied in the fields of electro-solid devices, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., to achieve the effect of ensuring spectral stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

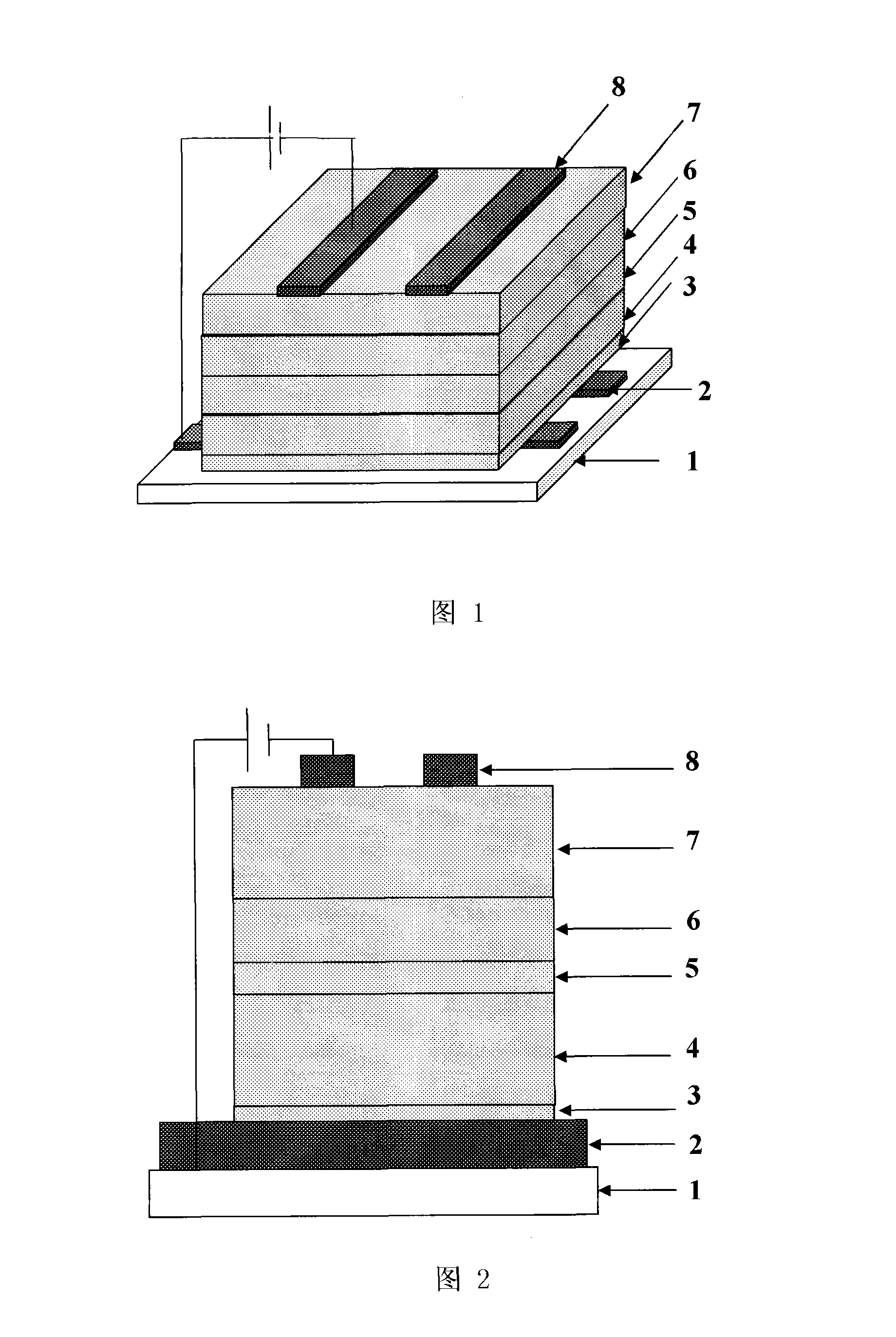

[0030] The ITO on ITO glass was first photolithographically formed into electrodes 4 mm wide and 30 mm long, then cleaned, blown dry with nitrogen, and treated with oxygen plasma for 2 min. 1 to 5 x 10 in vacuum -4 In the coating system of Pa, V is sequentially deposited on the ITO electrode 2 O 5 Vanadium pentoxide hole injection layer, NPB hole transport layer, TCTA electron blocking layer, FIrpic and (fbi) 2 The light-emitting layer composed of Ir(acac) co-doped in mCP, the TAZ electron transport layer, and the composite cathode composed of LiF and metal Al, the two electrodes intersect each other to form the light-emitting area of the device, and the area of the light-emitting area is 16 square millimeters. The thickness of LiF in the metal cathode layer is 1 nm, the thickness of Al is 100 nm, and the metal oxide V 2 O 5 The thickness of the NPB, TCTA, mCP, and TAZ layers is 80, 5, 20, and 40 nm, respectively, and the total thickness of these organic layers is 145 ...

Embodiment 2

[0032] The ITO on ITO glass was first photolithographically formed into electrodes 4 mm wide and 30 mm long, then cleaned, blown dry with nitrogen, and treated with oxygen plasma for 2 min. 1 to 5 x 10 in vacuum -4 In the coating system of Pa, V is sequentially deposited on the ITO electrode 2 O 5 Vanadium pentoxide hole injection layer, NPB hole transport layer, TCTA electron blocking layer, FIrpic and (fbi) 2 The light-emitting layer composed of Ir(acac) co-doped in mCP, the TAZ electron transport layer, and the composite cathode composed of LiF and metal Al, the two electrodes intersect each other to form the light-emitting area of the device, and the area of the light-emitting area is 16 square millimeters. The thickness of LiF in the metal cathode layer is 1 nm, the thickness of Al is 200 nm, and the metal oxide V 2 O 5 The thickness of the NPB, TCTA, mCP, and TAZ layers is 80, 7.5, 20, and 40 nm, respectively, and the total thickness of these organic layers is 14...

Embodiment 3

[0034] The ITO on ITO glass was first photolithographically formed into electrodes 4 mm wide and 30 mm long, then cleaned, blown dry with nitrogen, and treated with oxygen plasma for 2 min. 1 to 5 x 10 in vacuum -4 In the coating system of Pa, MoO is sequentially evaporated on the ITO electrode 3 Molybdenum trioxide hole injection layer, NPB hole transport layer, TCTA electron blocking layer, FIrpic and (fbi) 2 The light-emitting layer composed of Ir(acac) co-doped in mCP, the TAZ electron transport layer, and the composite cathode composed of LiF and metal Al, the two electrodes intersect each other to form the light-emitting area of the device, and the area of the light-emitting area is 16 square millimeters. The thickness of LiF in the metal cathode layer is 1 nm, the thickness of Al is 200 nm, and the thickness of metal oxide MoO 5 The thickness of the NPB, TCTA, mCP, and TAZ layers is 60, 10, 20, and 40 nm, respectively, and the total thickness of these organic laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com