A kind of fluorescent material, preparation method and application

A fluorescent material and reaction technology, which is applied in the field of preparation and fluorescent materials, can solve the problem of low luminous efficiency of luminescent materials, and achieve the effects of reducing the luminescence quenching process, improving luminous efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method for the above-mentioned fluorescent material, including:

[0047] Step A, preparation of intermediate E containing naphthyridine unit:

[0048] Specifically, intermediate E can adopt the following synthetic route.

[0049]

[0050] In the formula, X and Y are not H at the same time, and the synthesis steps are: disperse compound A and compound B in an organic solvent, for example, using toluene as a solvent, reflux for more than 10 minutes under a protective atmosphere (argon can be used), and separate the compound C; then compound C is placed in diphenyl ether, refluxed for 4-8 hours, separated and purified to obtain compound D; then compound D is placed in phosphorus oxychloride, and the catalyst N,N-dimethylaniline is added to protect Reflux under atmosphere for 1-4 hours, separate and purify to obtain the intermediate E.

[0051]Step B, under anaerobic conditions, dissolve the intermediate E, compound P...

Embodiment 1

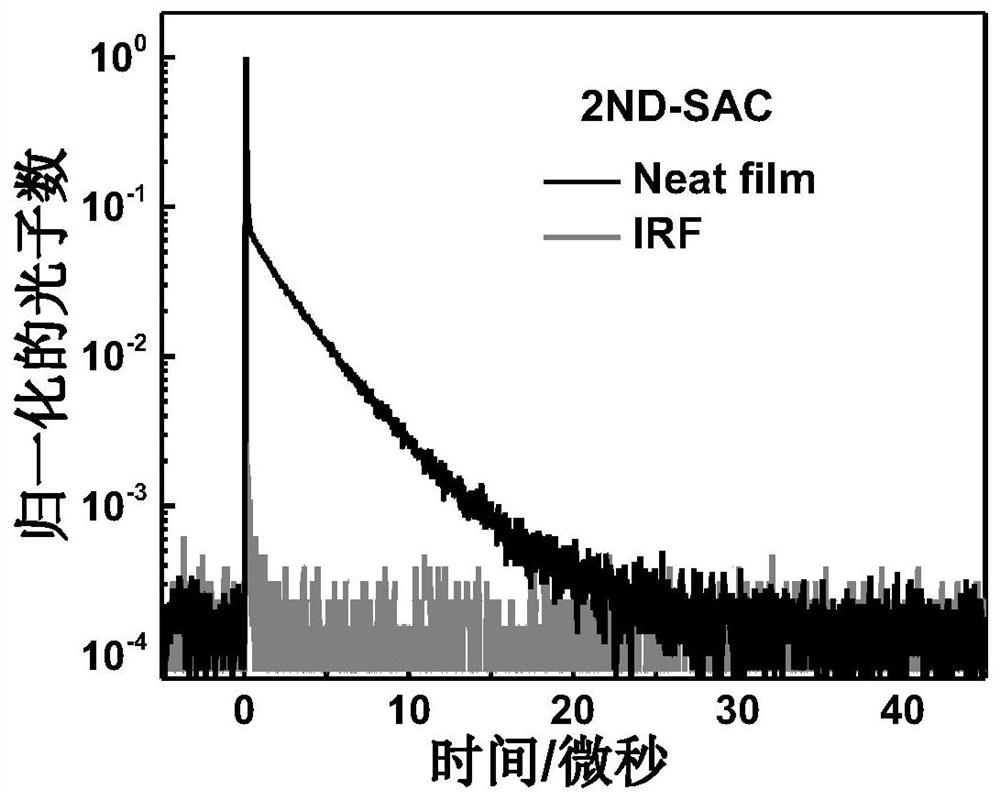

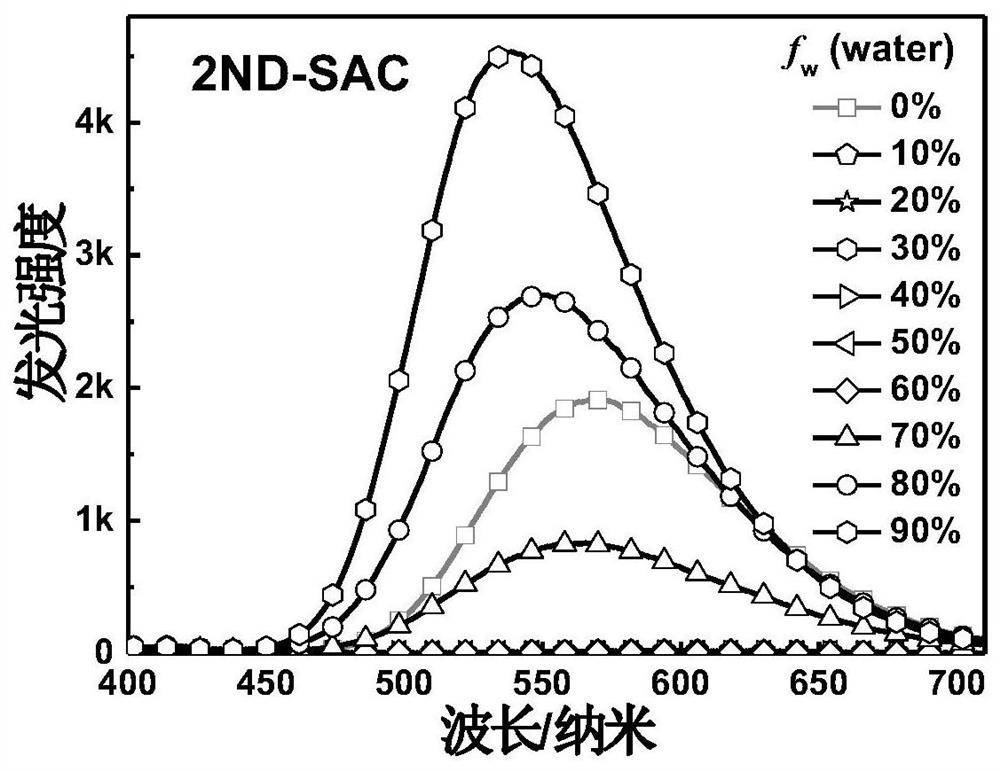

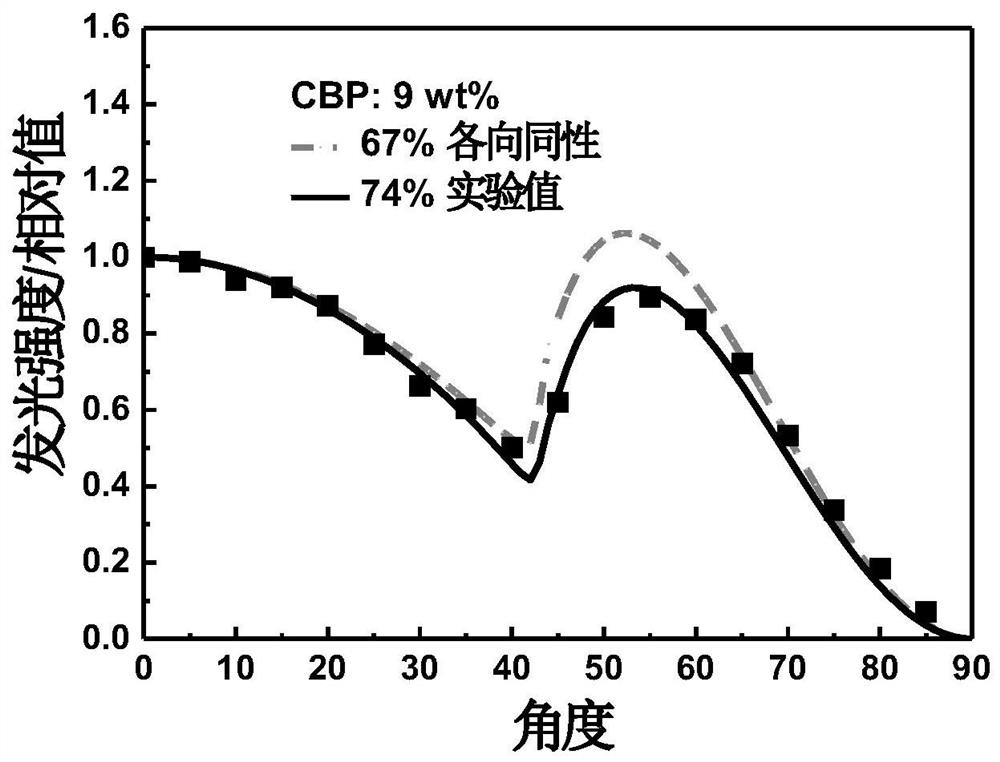

[0063] Compound of Example 1 Preparation of (2ND-SAC).

[0064] (1) Synthesis of Intermediate 6-A

[0065]

[0066] In a 250 mL two-neck round bottom flask, 3-aminopyridine (1.88 g, 20 mmol), dibutyl maleate (2.88 g, 20 mmol) and 100 mL of toluene were added. The mixture was refluxed and stirred for 15 minutes under an argon atmosphere, cooled to room temperature, and 250 mL of petroleum ether was added, resulting in a large amount of precipitation, filtered by suction, and dried to obtain 3.46 g of a light yellow solid with a yield of 90%.

[0067] (2) Synthesis of Intermediate 6-B

[0068] In a 250mL round-bottomed flask, add Intermediate 6-A (3.46g, 18mmol) and 130mL of diphenyl ether, the mixture is refluxed at 250°C for 4 hours under argon atmosphere, filtered with suction, and the solid is washed with dichloromethane to obtain a brown Crude product 1.31g, yield 50%.

[0069] (3) Synthesis of intermediate ND-Cl

[0070] In a 50mL two-neck round bottom flask, add ...

Embodiment 2

[0081] Compound of Example 2 Preparation of (2PND-SAC).

[0082] (1) Synthesis of Intermediate 7-A

[0083]

[0084] In a 250 mL two-neck round bottom flask, add 3-amino-4-chloropyridine (2.56 g, 20 mmol), dibutyl maleate (2.88 g, 20 mmol) and 100 mL of toluene. The mixture was refluxed and stirred for 15 minutes under an argon atmosphere, cooled to room temperature, and 250 mL of petroleum ether was added to produce a large amount of precipitate, which was filtered by suction.

[0085] After drying, 4.16 g of a light yellow solid was obtained with a yield of 92%.

[0086] (2) Synthesis of intermediate 7-B

[0087] In a 250mL round-bottomed flask, add Intermediate 7-A (4.07g, 18mmol) and 130mL of diphenyl ether, and the mixture is refluxed at 255°C for 5 hours under an argon atmosphere, filtered with suction, and washed with dichloromethane to obtain a brown Crude product 1.62g, yield 50%.

[0088] (3) Synthesis of intermediate ND-2Cl

[0089] In a 50mL two-necked ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com