Novel pyrithione zinc/montmorillonite/tourmaline composite antibacterial anion releasing agent and preparation method thereof

A zinc pyrithione and compound antibacterial technology, which is applied in botany equipment and methods, biocides, disinfectants, etc., can solve the problems of antibacterial performance decline, discoloration, etc., and achieve fast sterilization speed, wide application, and instant antibacterial effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

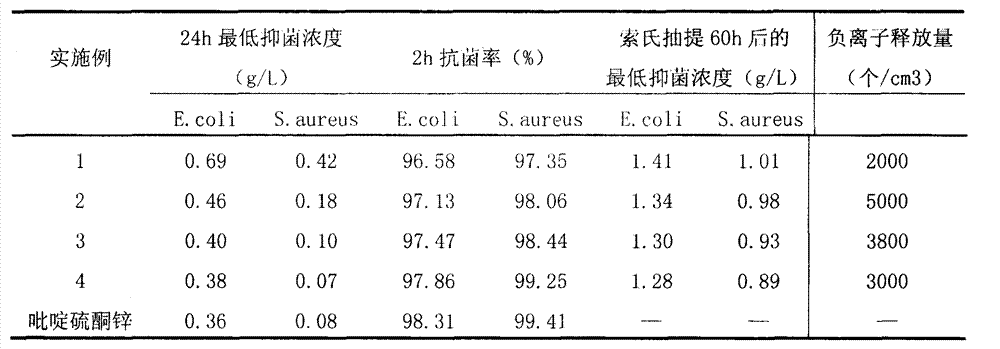

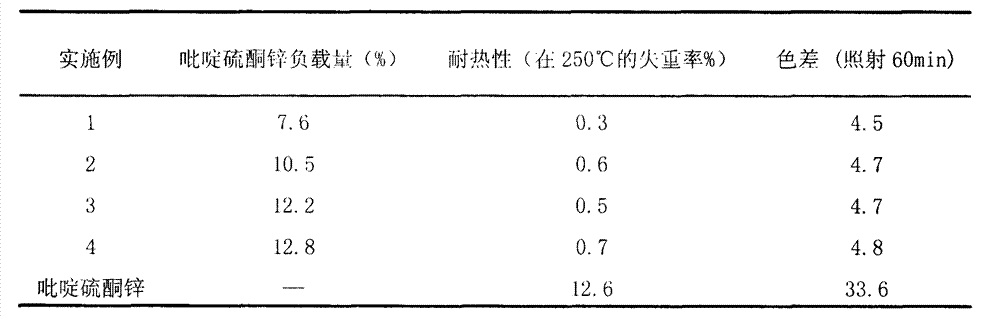

Embodiment 1

[0028] (1) stirring and dispersing calcium-based montmorillonite in distilled water to make a uniform slurry with a mass fraction of 5%;

[0029] (2) Slowly add zinc chloride having a zinc content of 5% of the mass of montmorillonite to the slurry in step (1) under stirring, and stir at a constant temperature of 60° C. for 3 hours;

[0030] (3) washing the slurry in step (2) 3 times, filtering, then drying and pulverizing the obtained filter cake to 300 mesh, to obtain zinc-loaded montmorillonite;

[0031] (4) the zinc-loaded montmorillonite and dimethyl sulfoxide in the step (3) are made into a slurry with a mass fraction of 5%;

[0032](5) Add tourmaline equivalent to 20% of the quality of zinc-loaded montmorillonite into the slurry of step (4), stir vigorously for 20 minutes, then slowly add sodium pyrithione with 10% of the quality of zinc-loaded montmorillonite under stirring into the mixed slurry, detect and adjust the pH value of the slurry to 3 with 1mol / L hydrochlori...

Embodiment 2

[0035] (1) stirring and dispersing sodium-calcium-based montmorillonite in distilled water to make a uniform slurry with a mass fraction of 10%;

[0036] (2) Slowly add zinc sulfate with a zinc content of 10% of the mass of montmorillonite to the slurry in step (1) under stirring, and stir at a constant temperature at 70° C. for 4 hours;

[0037] (3) washing the slurry in step (2) 4 times, filtering, then drying and pulverizing the obtained filter cake to 400 mesh, to obtain zinc-loaded montmorillonite;

[0038] (4) the zinc-loaded montmorillonite and dimethyl sulfoxide in the step (3) are made into a slurry with a mass fraction of 10%;

[0039] (5) Add tourmaline equivalent to 80% of the quality of zinc-loaded montmorillonite into the slurry of step (4), stir vigorously for 20 minutes, then slowly add 20% sodium pyrithione to the mixed slurry under stirring, and detect And use 1mol / L hydrochloric acid to adjust the pH value of the slurry to 4, and stir at a constant temperat...

Embodiment 3

[0042] (1) stirring and dispersing sodium-based montmorillonite in distilled water to make a uniform slurry with a mass fraction of 10%;

[0043] (2) Slowly add zinc nitrate with a zinc content of 7% of the mass of montmorillonite to the slurry in step (1) under stirring, and stir at a constant temperature of 65° C. for 3 hours;

[0044] (3) washing the slurry in step (2) 4 times, filtering, then drying and pulverizing the obtained filter cake to 400 mesh, to obtain zinc-loaded montmorillonite;

[0045] (4) the zinc-loaded montmorillonite and dimethyl sulfoxide in the step (3) are made into a slurry with a mass fraction of 10%;

[0046] (5) Tourmaline equivalent to 60% of zinc-loaded montmorillonite quality is added in the slurry of step (4), vigorously stirred for 20 minutes, and then 30% sodium pyrithione was slowly added to the slurry of step (4) under stirring. In the slurry, detect and adjust the pH value of the slurry to 4 with 1mol / L hydrochloric acid, and stir at a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com