Luminous pearl nucleus and preparation method thereof as well as method for cultivating luminous pearls

A bead core and pearl technology, which is applied in the field of high-brightness luminous bead cores, can solve problems such as poor luminous rate of luminous pearls, lower value of luminous pearls, unstable chemical structure, etc., and achieve long afterglow time, low cost, high yield and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

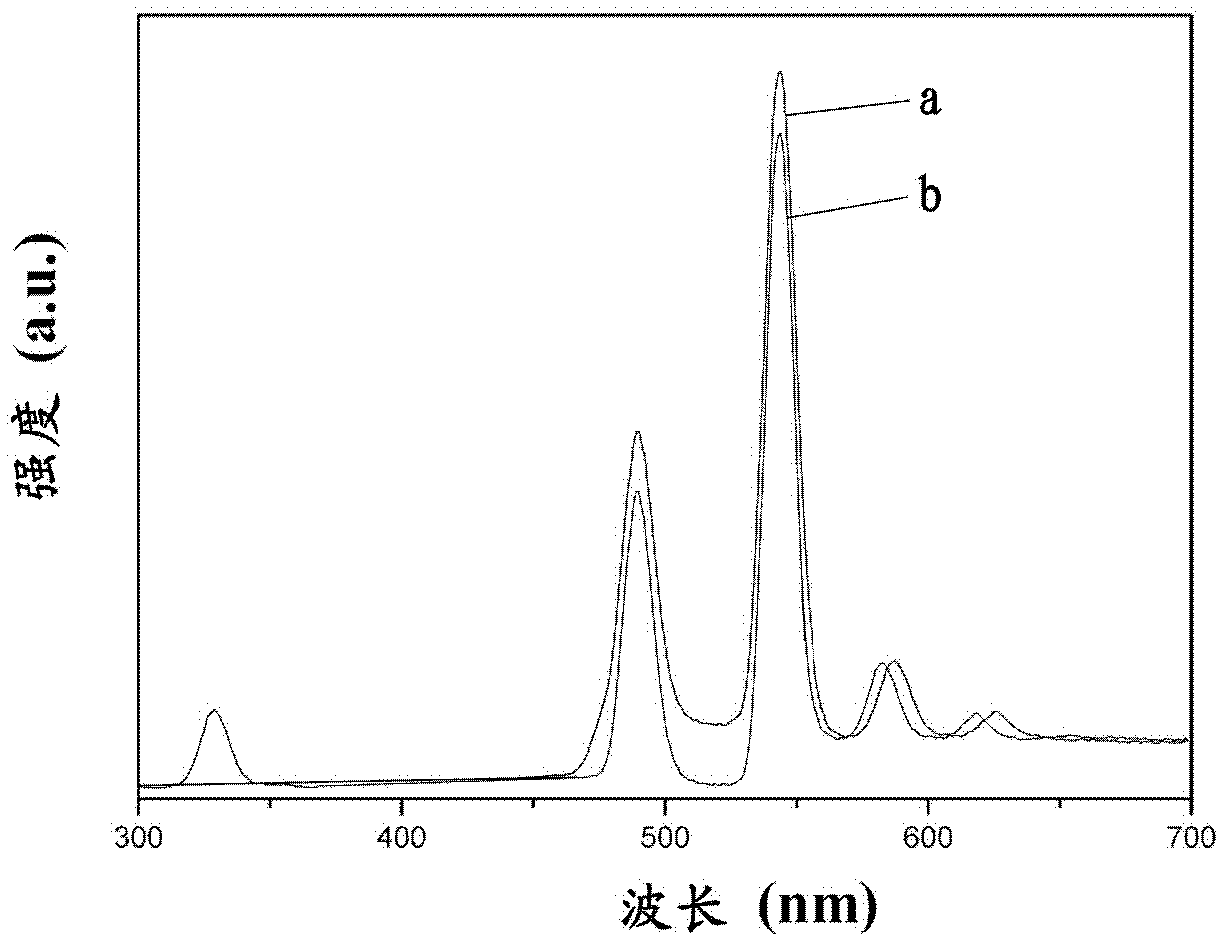

[0042] Embodiment 1: the preparation of green luminous pearl

[0043] Preparation of luminescent bead core: select 1000g of composite fluorescent material emitting green fluorescence, wherein phase A (Sr, Eu, Dy) 0.92 (Al, B) 2.00 o 3.92 The weight percentage is 69%; Phase B (Sr, Eu, Dy) 3.68 (Al, B) 14 o 24.68 The weight percentage is 31%. Put the composite fluorescent material into a crucible, put the crucible into an electric furnace with carbon powder as a reducing atmosphere, and heat it. After 5 hours, the temperature of the furnace is slowly raised to 1500 ° C, and the pressure is increased to 2.1 atmospheres. After 3 hours of constant temperature and constant pressure , in the molten state, it is directly pressed into a round core with a mold.

[0044] Preparation of small pieces of cells: Select suitable seawater pearl oysters, first use a scalpel to cut off the front and rear adductor muscles of the small piece of clam, make the two shells open by themselves, r...

Embodiment 2

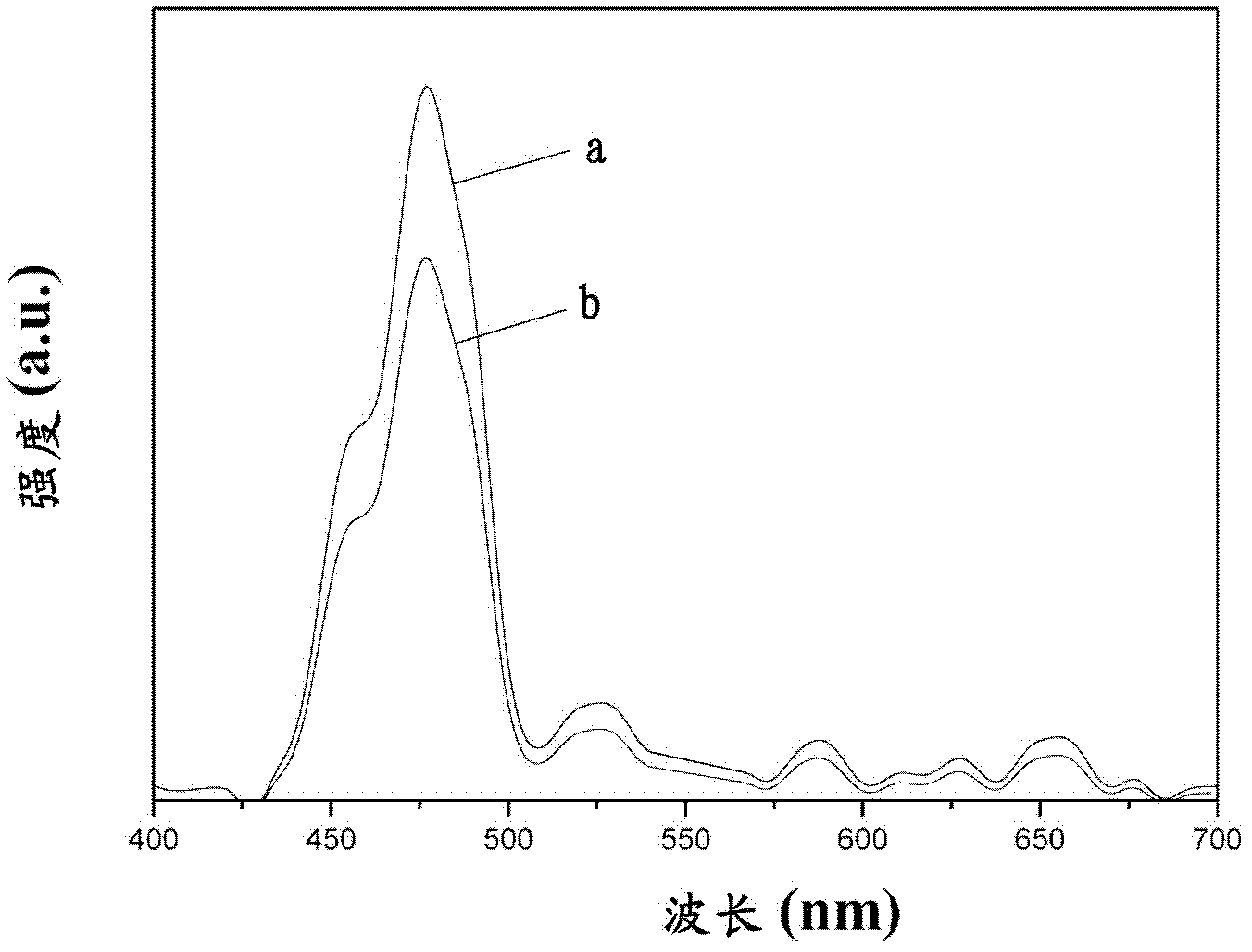

[0048] Embodiment 2: the cultivation of blue fluorescent luminous pearl

[0049] Except selecting 850g of composite fluorescent material and adding 150g of natural crystal (purity: 99.8% by weight) to the fluorescent composite material, the same steps as in Example 1 were used to prepare blue fluorescent luminous pearls. The composite fluorescent material phase A (Sr, Eu, Dy) 0.92 (Al, B) 2.00 o 3.92 The weight ratio of is 31%; Phase B (Sr, Eu, Dy) 3.68 (Al, B) 14 o 24.68 The weight ratio is 69%.

[0050] Similarly, measure the prepared luminous bead core and the luminous spectrum of the luminous pearls cultivated with it with HP800 type spectrometer, see respectively figure 2 Line a and line b in. It can be seen from the figure that the luminous pearl can emit blue light, and its luminous intensity is almost equal to that of the luminous bead core. Further measurement of the afterglow time of the prepared blue luminous pearls can reach 87 hours.

Embodiment 3

[0051] Embodiment 3: the cultivation of yellow fluorescent luminous pearl

[0052] Except for selecting 900 g of composite fluorescent materials and adding 100 g of natural crystal (purity: 99.8% by weight) to the fluorescent composite material, the same steps as in Example 1 were used to prepare yellow fluorescent luminous pearls. The composite fluorescent material phase A (Sr, Ca, Eu, Dy) 0.92 (Al, B) 2.00 o 3.92 ; Phase B is (Sr, Ca, Dy) 3.68 (Al, B) 14 o 24.68 ; Wherein the phase A is 85%, and the phase B is 15%.

[0053] Similarly, measure the prepared luminous bead nucleus and the luminous spectrum of the luminous pearl that cultivates with it with HP800 type spectrometer, see respectively image 3 Line a and line b in. It can be seen from the figure that the luminous pearl can emit yellow light, and its luminous intensity is almost equal to that of the luminous bead core. After further measurement, the afterglow time of the prepared yellow luminous pearl can rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com