Display, thin film transistor array substrate and manufacturing process thereof

A technology of thin film transistors and array substrates, applied in the field of liquid crystal displays, can solve problems such as high complexity, low yield, and many process steps, and achieve the effects of reducing complexity, improving production efficiency, and simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

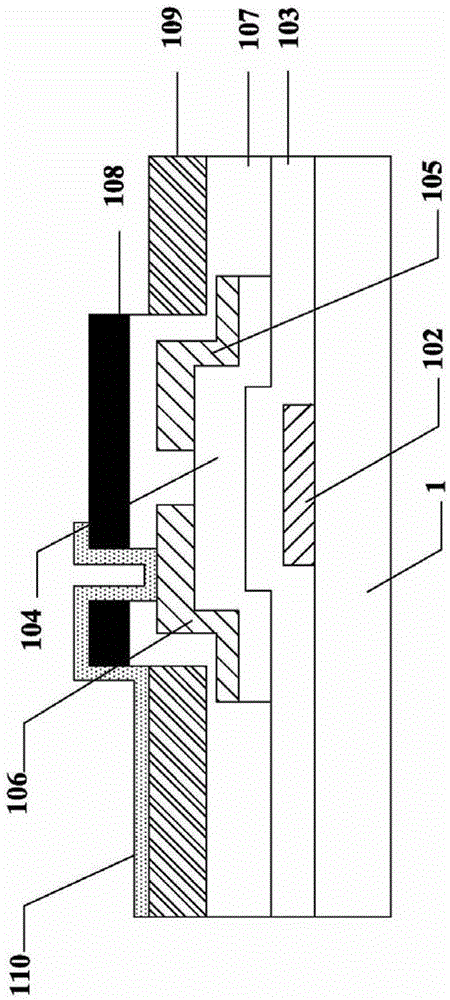

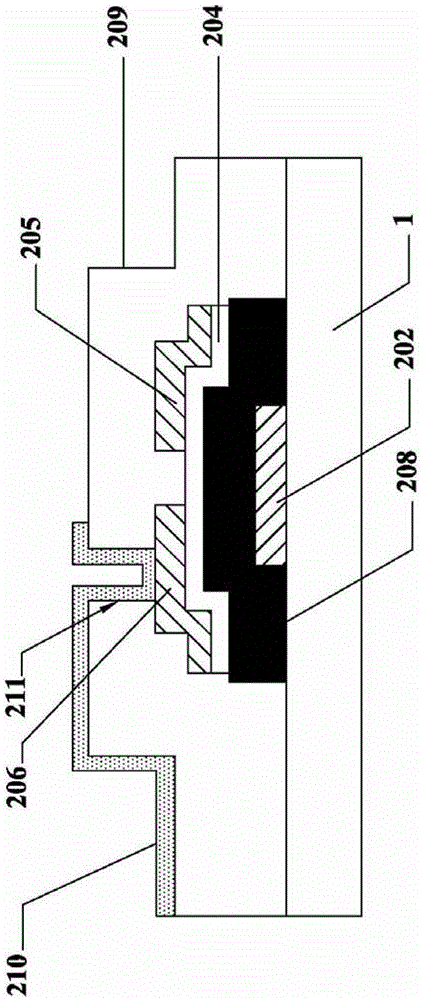

[0032] The thin film transistor array substrate of the present invention uses black resin as the insulating layer of the gate, and simultaneously serves as a black matrix for dividing sub-pixels. Because the gate insulating layer of the black resin material is thick and the dielectric constant is high, the performance of the thin film transistor will be reduced, so the technical solution of the present invention is also doped with a small amount of metal powder (such as silver powder, copper powder, etc.) in the black resin, In order to reduce its dielectric constant and ensure the good performance of the thin film transistor.

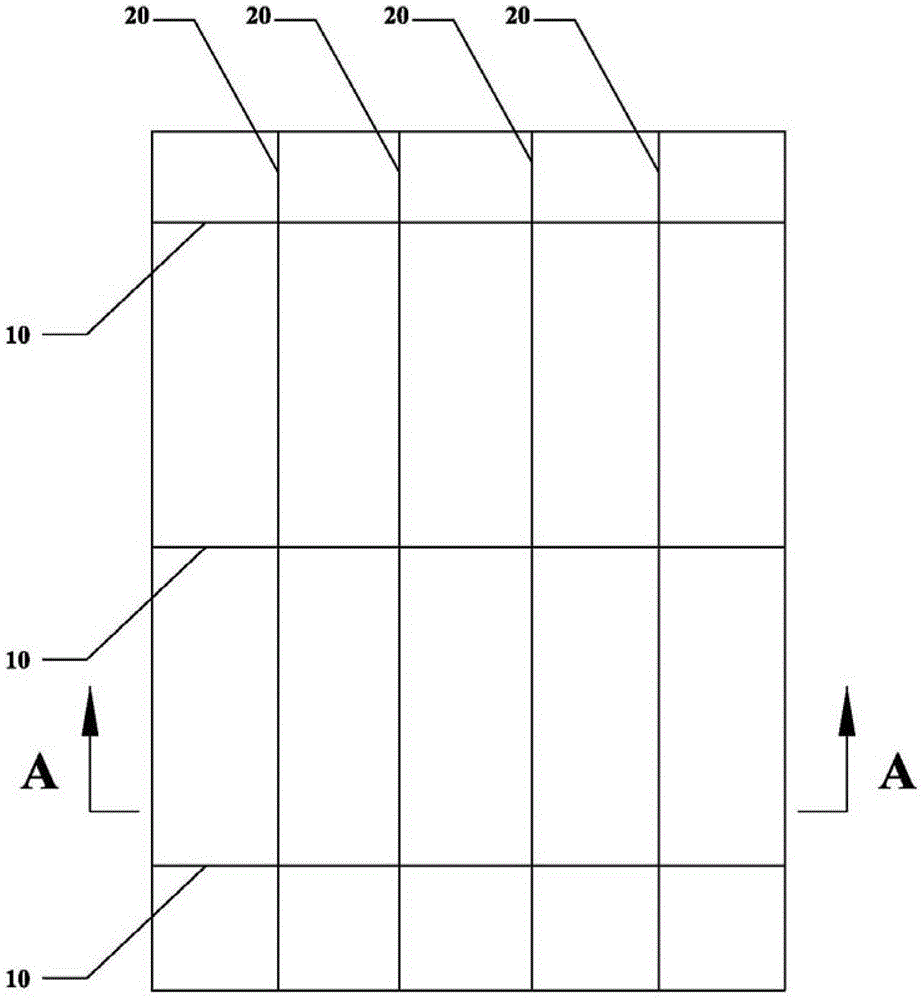

[0033] Such as figure 2 , image 3 As shown, the embodiment of the thin film transistor array substrate of the present invention includes gate lines 10, data lines 20, and pixel electrodes 210 formed in the pixel regions defined by the gate lines 10 and data lines 20, and also includes:

[0034] a gate electrode 202 formed on the substrate 1;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com