Composite steel-plastic pressure pipe for conveying hot water

A technology of steel-plastic composite and pressure pipes, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., which can solve the problems of large market demand for hot water delivery pipes, poor polyethylene oxygen barrier performance, and short service life of pipes, etc. problem, to achieve the effect of long service life, prolong service life and increase working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

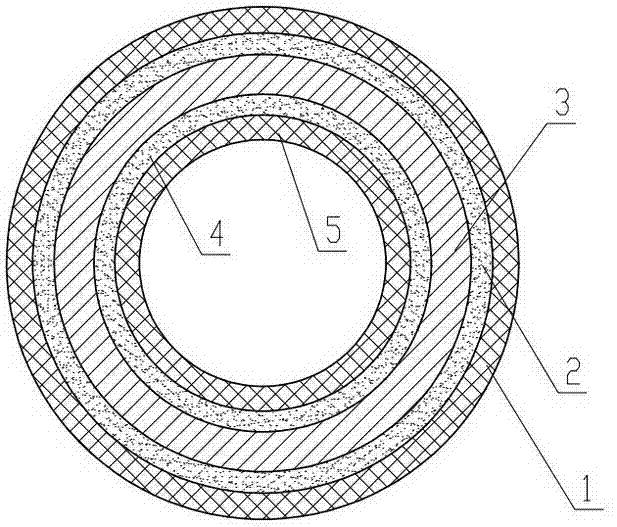

[0025] Such as figure 1 From the shown embodiment, it can be known that the steel-plastic composite pressure pipe for conveying hot water according to the present invention includes an outer polyethylene layer 1, a stainless steel pipe layer 3 and an inner polyethylene layer 5 from outside to inside in sequence. The outer polyethylene layer 1 and the stainless steel tube layer 3 are bonded to each other through the outer adhesive layer 2 ; the stainless steel tube layer 3 and the inner polyethylene layer 5 are bonded to each other through the inner adhesive layer 4 .

[0026] The adhesives used in the outer adhesive layer 2 and the inner adhesive layer 4 are all hot melt adhesives.

[0027] Polyethylene can be divided into high-density polyethylene, low-density polyethylene and linear low-density polyethylene according to different polymerization methods, molecular weight and chain structure.

[0028] Low Density Polyethylene (LDPE) is commonly known as high-pressure polyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com