A kind of textile auxiliary agent for textile sizing and preparation method thereof

A textile auxiliaries and textile technology, which are applied in the field of textile sizing auxiliaries and their preparation, can solve the problems of limited yarn adhesion and cannot be used alone, so as to reduce environmental load, increase industrial added value, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

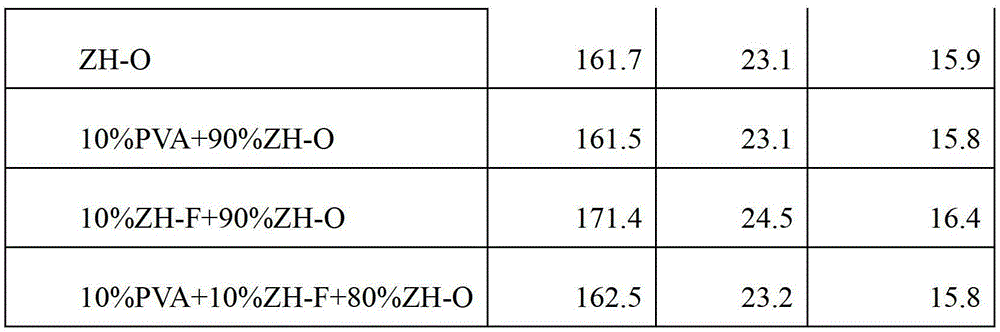

Embodiment 1

[0026] Formula quantity: lignin: 60g, acrylic acid 180g: methyl acrylate 200g, hydrogen peroxide 50g, water 800g, ammonium persulfate 40g, azobisisobutyronitrile 40g, gum arabic 45g, low-viscosity starch 1800g, sodium carbonate 80g, defoaming Dose 25g.

[0027] making process:

[0028] (1) In a 2000mL reactor with a jacket and reflux, put lignin, water, and gum arabic in the amount specified in the formula, turn on the stirring motor of the reactor and the steam pressure valve of the jacket, and raise the temperature to within the range of 40-65°C ;

[0029] (2) In the range of 40-65°C, use hydrogen peroxide and ammonium persulfate to activate lignin, and the activated lignin becomes activated lignin with relatively stable active groups;

[0030] (3) In the range of 40-65°C, use concentrated sulfuric acid to adjust the pH value of the system to 3-4;

[0031] (4) Add the mixture of acrylic acid, methyl acrylate, and azobisisobutyronitrile dropwise in the range of 60-90°C, an...

Embodiment 2

[0036] Formula quantity: lignin: 180g, methacrylic acid 60g: ethyl acrylate 50g, hydrogen peroxide 50g, water 800g, potassium persulfate 1g, azobisisobutyronitrile 1g, squash gum 20g, low-viscosity starch 600g, sodium carbonate 50g , Defoamer 4g.

[0037] making process:

[0038] (1) In a 2000mL reactor with a jacket and reflux, put lignin, water, and safflower gum in the specified amount of the formula, turn on the stirring motor of the reactor and the steam pressurization valve of the jacket, and raise the temperature to 40-65°C Inside;

[0039] (2) In the range of 40-65°C, use hydrogen peroxide and potassium persulfate to activate lignin, and the activated lignin becomes activated lignin with relatively stable active groups;

[0040] (3) In the range of 40-65°C, use concentrated sulfuric acid to adjust the pH value of the system to 3-4;

[0041] (4) Add the mixture of methacrylic acid, ethyl acrylate and azobisisobutyronitrile dropwise in the range of 60-90°C, and comple...

Embodiment 3

[0046] Formula quantity: lignin: 180g, itaconic acid 150g: butyl acrylate 180g, hydrogen peroxide 50g, water 800g, ammonium persulfate 1g, azobisisobutyronitrile 1g, squash gum 30g, low-viscosity starch 1500g, sodium carbonate 30g, Defoamer 4g.

[0047] Preparation process: (1) In a 2000mL reactor with a jacket and reflux, put lignin, water, and safflower gum in the amount specified in the formula, turn on the stirring motor of the reactor and the steam pressurization valve of the jacket, and raise the temperature to 40- Within the range of 65°C;

[0048] (2) In the range of 40-65°C, use hydrogen peroxide and ammonium persulfate to activate lignin, and the activated lignin becomes activated lignin with relatively stable active groups;

[0049] (3) In the range of 40-65°C, use concentrated sulfuric acid to adjust the pH value of the system to 3-4;

[0050] (4) Add the mixture of itaconic acid, butyl acrylate and azobisisobutyronitrile dropwise in the range of 60-90°C, and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com