Composite phase change heat storage material and preparation method thereof

A heat storage material and composite phase change technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the undisclosed problems such as the preparation method of sodium sulfate decahydrate heat storage phase change materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

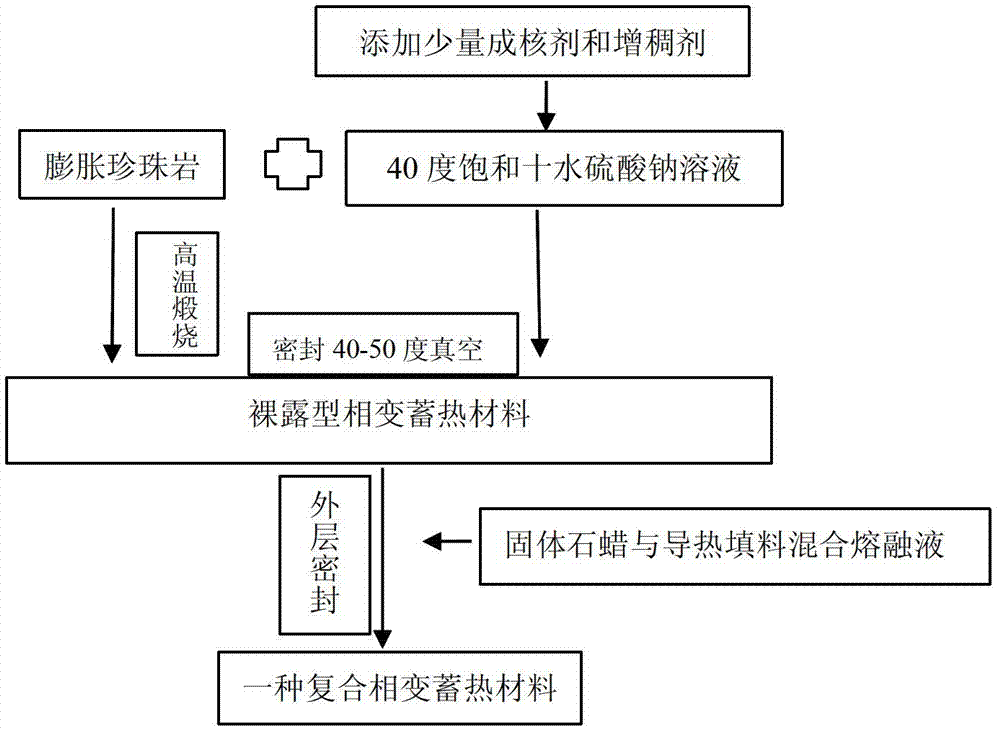

Image

Examples

preparation example Construction

[0010] The composite phase change heat storage material of the present invention is characterized in that the main constituent materials are expanded perlite as the adsorption carrier, sodium sulfate decahydrate as the heat storage matrix, and industrial solid paraffin as the coating sealing material. Among them, the expanded perlite must be calcined at high temperature; in order to facilitate the adsorption of sodium sulfate decahydrate on the carrier, it is prepared as a saturated aqueous solution at 40°C. Finally, in order to reduce the loss of hydrated salt crystallization water during the phase change process and prolong the service life of the thermal storage material, industrial solid paraffin is used to coat and seal the periphery of the material, and a certain amount of thermally conductive filler is added during the coating process. In order to improve the overall thermal conductivity of the material and enhance its thermal response capability. The mass composition o...

Embodiment 1

[0017] At 40°C, 40.3 parts of sodium sulfate decahydrate and 13.9 parts of distilled water were mixed and melted in a beaker. Place 0.8 parts of borax and 1.2 parts of sodium carboxymethyl cellulose in a mortar, grind them finely, add them into the blended molten liquid and mix evenly.

[0018] Take 18.6 parts of expanded perlite that has been calcined at a high temperature above 450°C and add it to the mixed solution prepared in the previous step, stir and adsorb and blend for 1 hour under the condition of a sealed 40°C and a vacuum of 150kpa. After the adsorption is complete, gradually cool to room temperature.

[0019] Mix and melt 24 parts of solid paraffin and 1.2 parts of expandable graphite at a temperature higher than the melting point of paraffin, and use conventional methods to make the molten liquid form a solid sealing layer on the surface of the heat storage material prepared in the previous step to obtain a composite Phase change thermal storage materials. A sam...

Embodiment 2

[0021] At 40°C, 39.8 parts of sodium sulfate decahydrate and 13.7 parts of distilled water were mixed and melted in a beaker. Put 1.1 parts of nano-alumina and 1.6 parts of sodium carboxymethyl cellulose in a mortar, grind them finely, add them into the blended melt and mix evenly.

[0022] Take 18.1 parts of expanded perlite that has been calcined at a high temperature above 450°C and add it to the mixed solution prepared in the previous step. Stir and adsorb and blend for 1.5 hours under the condition of a sealed 45°C and a vacuum of 175kpa. After the adsorption is complete, gradually cool to room temperature.

[0023] Mix and melt 23.9 parts of solid paraffin and 1.8 parts of silicon carbide at a temperature higher than the melting point of paraffin, and use conventional methods to make the molten liquid form a solid sealing layer on the surface of the heat storage material prepared in the previous step to obtain a composite phase heat storage material. A sample of the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase change enthalpy | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com