A vermicular agent for efficient vermicular graphite cast iron, its preparation and production method

A technology of vermicular graphite cast iron and vermicular agent, which is applied in the proportioning field of high-efficiency vermicular graphite cast iron, can solve the problems of inability to realize stable production of high-quality vermicular graphite cast iron, difficulty in controlling vermicularization rate, waste of resources by carbides, etc., and achieve Improve the supercooling phenomenon of molten iron, reduce the oxidation phenomenon, and improve the quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

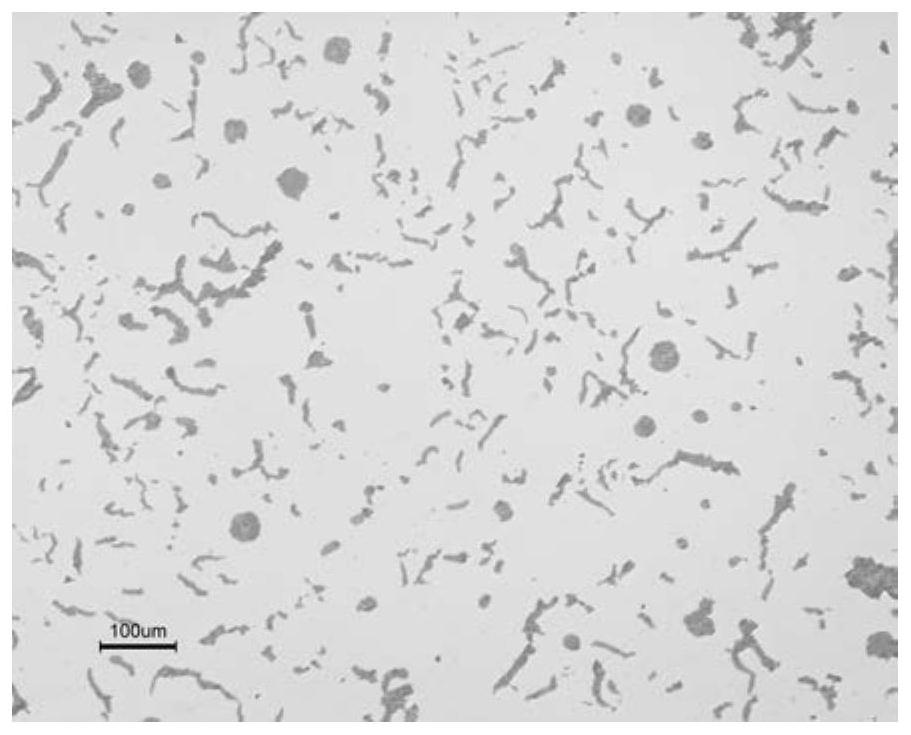

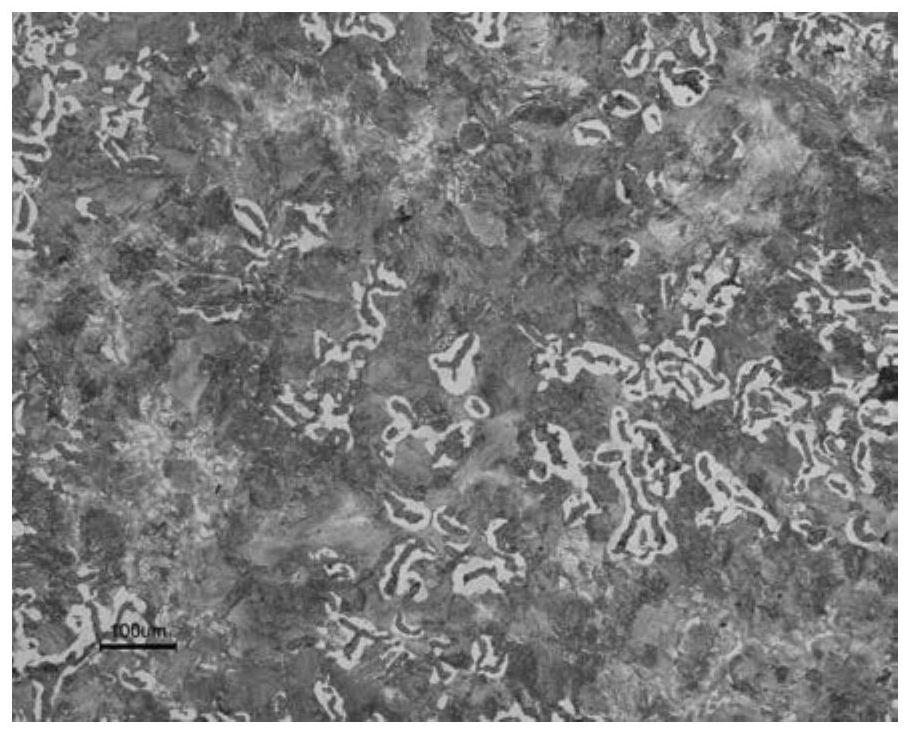

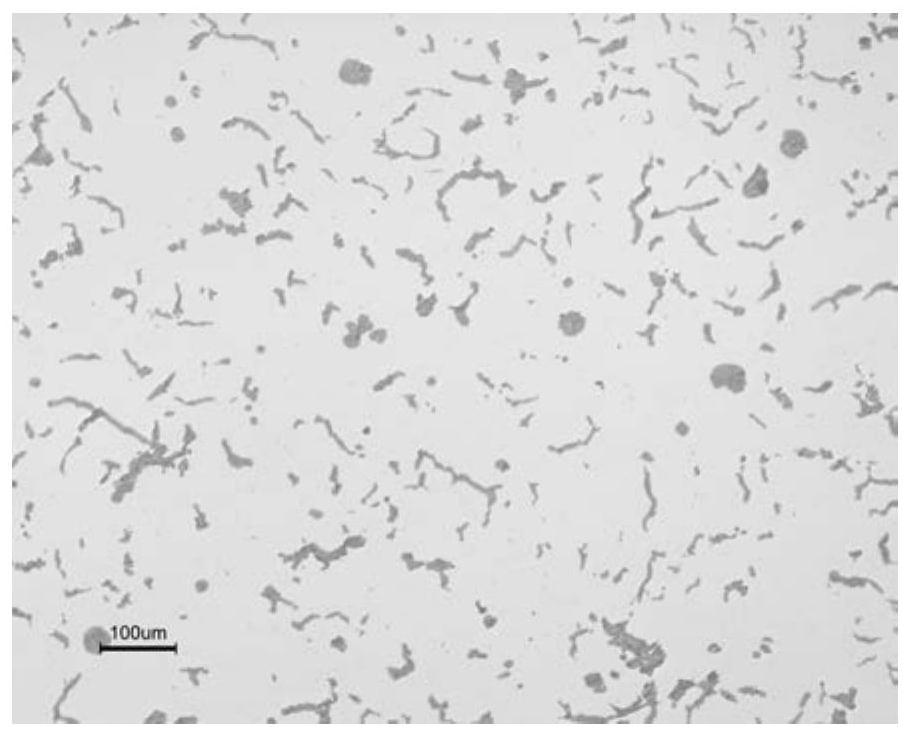

Image

Examples

Embodiment 1

[0034] A high-efficiency vermicular agent for vermicular graphite cast iron, the components of which are: Mg10%, Ca2%, Nb1%, RE1.5%, Si43%, and the balance is Fe and a small amount of impurities according to the mass percentage of elements.

[0035] The preparation method comprises the steps of:

[0036] (1) Accurately weigh high-quality raw materials: ferroniobium, rare earth, limestone, ferrosilicon, pure magnesium.

[0037] (2) The raw materials are put into the vacuum induction furnace for smelting according to the feeding order of ferroniobium, rare earth, limestone, ferrosilicon, and pure magnesium. After the raw materials are completely melted, they are kept for 30 minutes at a holding temperature of 1200-1280°C, and then poured into a metal ingot mold .

[0038] (3) The crushing process combined with the jaw crusher and gear crusher is adopted; the vibrating screen is used for screening to obtain a high-performance vermicular agent with a particle size of 3-5mm.

[0...

Embodiment 2

[0041] Example 2: A high-efficiency vermicular agent for vermicular graphite cast iron, its components are: Mg12%, Ca4%, Nb1%, RE1.5%, Si45%, the balance is Fe and a small amount of impurities according to the mass percentage of elements.

[0042] The preparation method comprises the following steps:

[0043] (1) Accurately weigh high-quality raw materials: ferroniobium, rare earth, limestone, ferrosilicon, pure magnesium.

[0044] (2) The raw materials are put into the vacuum induction furnace for melting according to the feeding order of ferroniobium, rare earth, limestone, ferrosilicon, and pure magnesium. After the raw materials are completely melted, they are kept for 45 minutes at a holding temperature of 1200-1280°C, and then poured into a metal ingot mold .

[0045] (3) The crushing process combined with the jaw crusher and gear crusher is adopted; the vibrating screening machine is used for screening to obtain a high-performance vermicular agent with a particle size ...

Embodiment 3

[0048] Embodiment 3: A high-efficiency vermicular agent for vermicular graphite cast iron, its composition is respectively according to element mass percentage: Mg12%, Ca3%, Nb1.8%, RE1.5%, Si47%, the balance is Fe and a small amount of impurity .

[0049] The preparation method comprises the following steps:

[0050] (1) Accurately weigh high-quality raw materials: ferroniobium, rare earth, limestone, ferrosilicon, pure magnesium.

[0051] (2) The raw materials are put into the vacuum induction furnace for smelting according to the feeding order of ferroniobium, rare earth, limestone, ferrosilicon, and pure magnesium. After the raw materials are completely melted, they are kept for 60 minutes at a holding temperature of 1200-1280°C, and then poured into a metal ingot mold .

[0052] (3) The crushing process combined with the Jaw Crusher and the Gear Crusher is used; the vibrating screen is used for screening to obtain a high-performance vermicular agent with a particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com