Selenium-micropore carrier composite, preparation method and application thereof

A microporous carrier and composite technology, applied in the field of electrochemical power sources, can solve problems such as unstable function, unsatisfactory battery capacity, and low discharge voltage of selenium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of selenium-microporous support composite positive electrode

[0043] The microporous carrier used in the experiment is microporous carbon (purchased from Japan Kuraray Co.), with a specific surface area of 920m 2 g -1 , the pore volume is 0.50cm 3 g -1 , the average pore size is 0.6nm, and the mass fraction of selenium in the prepared selenium-microporous carbon composite is 60%.

[0044] The preparation method of selenium-microporous carbon composite is as follows:

[0045] (1) Weigh selenium and microporous carbon according to the mass ratio of 3:2 and mix them evenly;

[0046] (2) The mixture of selenium and microporous carbon was heated at 0.2°C min -1 The heating rate is heated to 215 ° C and maintained for 12 hours, so that selenium is fully dispersed in the microporous carbon;

[0047] (3) Stop heating and return to room temperature to obtain a selenium-microporous carbon composite.

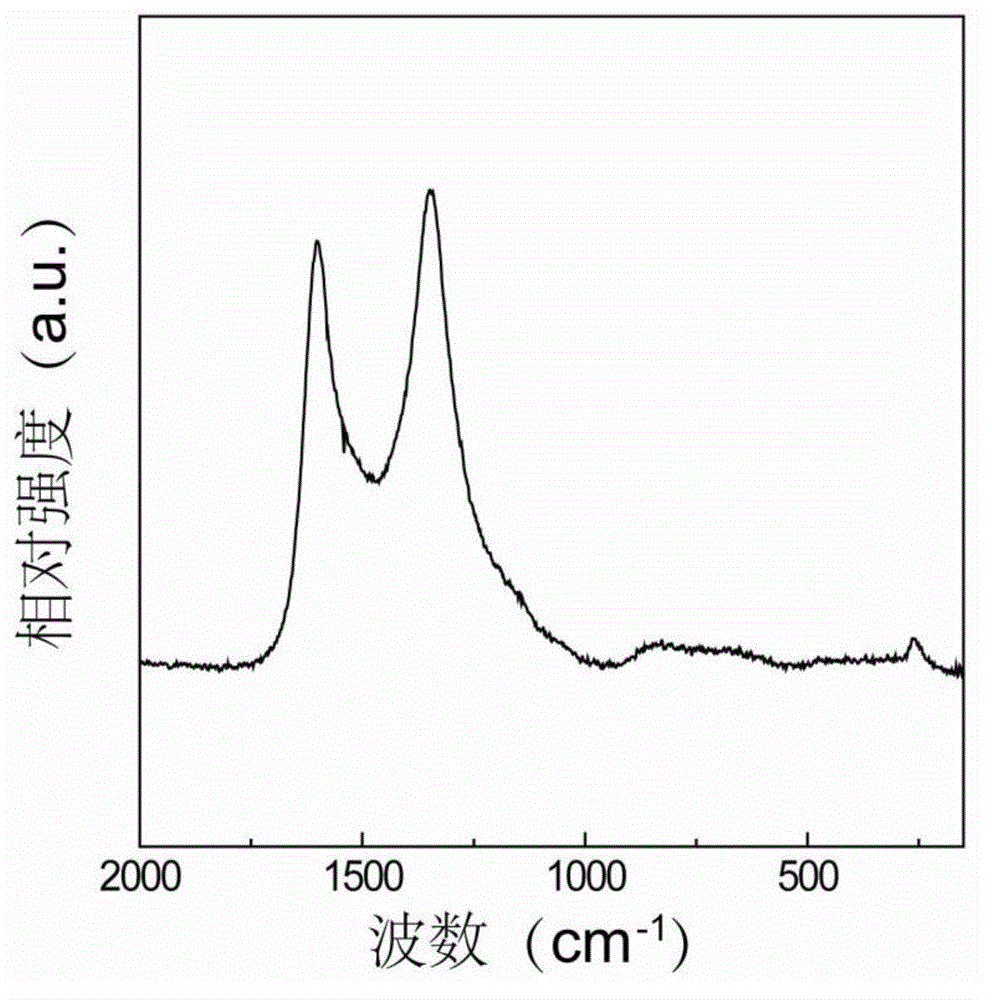

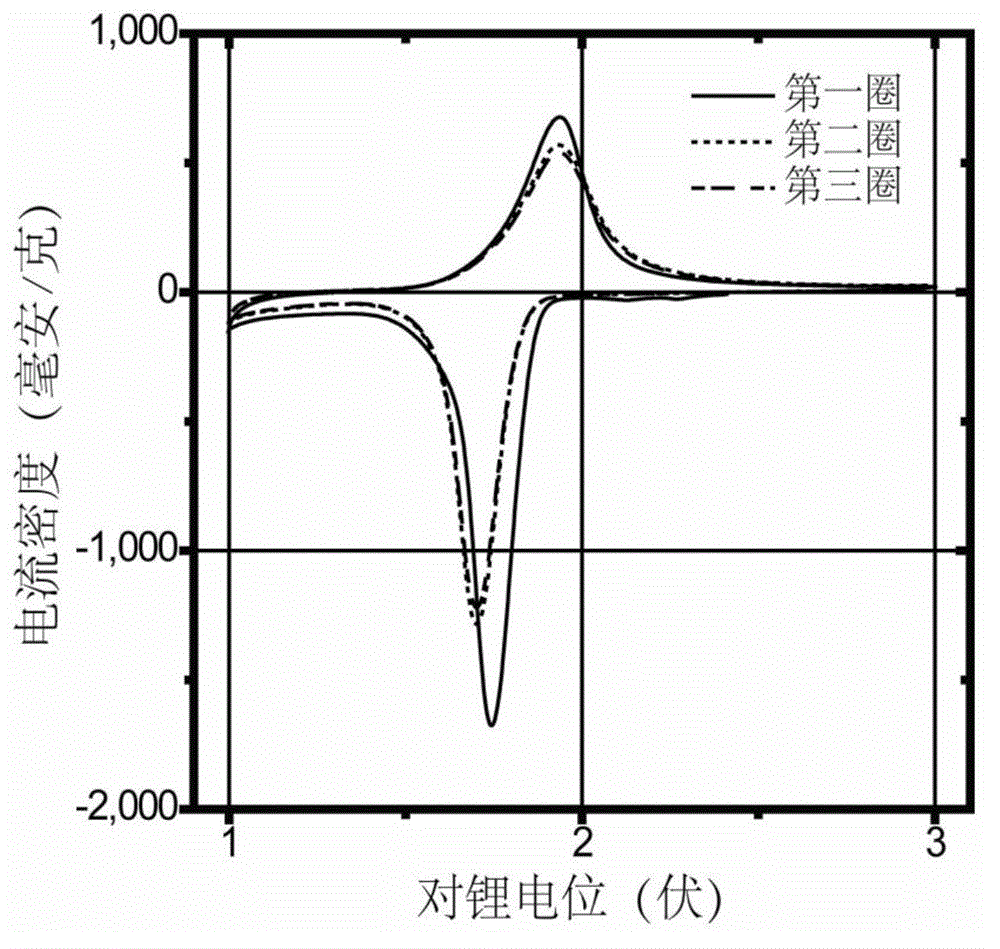

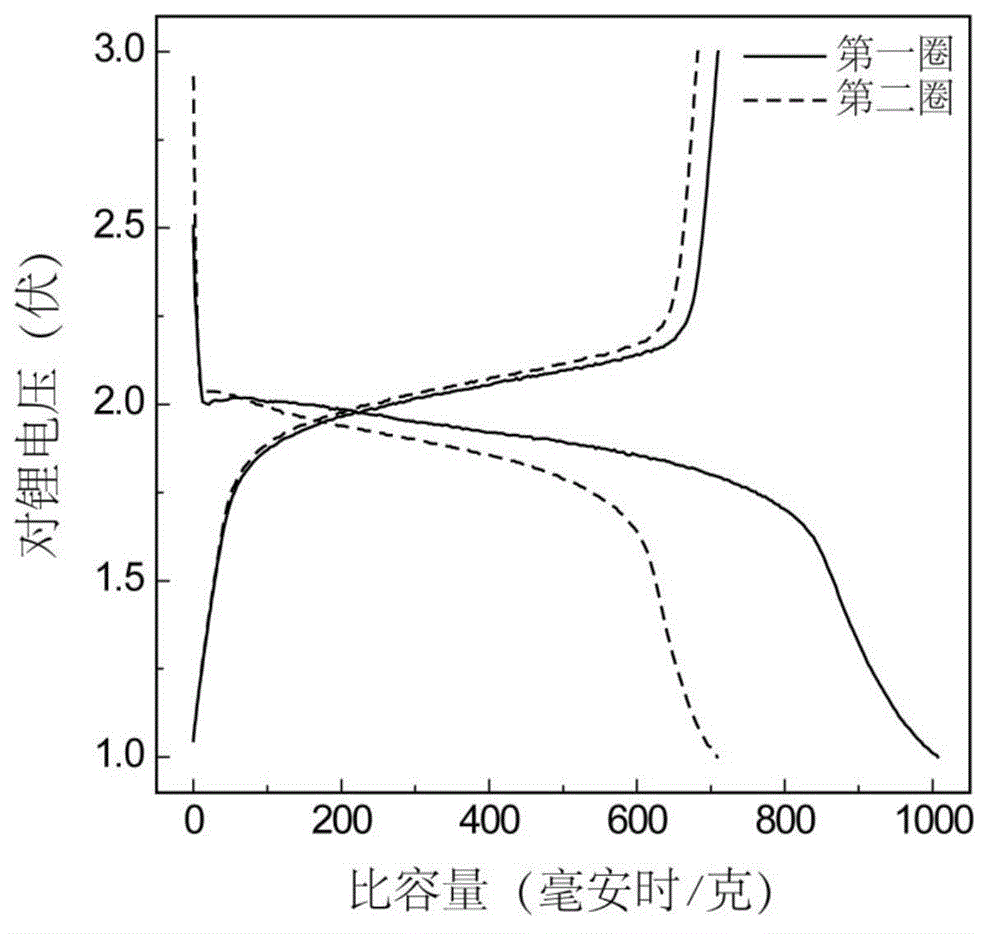

[0048] figure 1 Is the Raman spectrum of the seleniu...

Embodiment 2

[0060] (1) Preparation of selenium-microporous support composite positive electrode

[0061] The microporous carrier used in the experiment is microporous ferric oxide (purchased from Sigma-Aldrich Company), with a specific surface area of 300 m 2 g -1 , the pore volume is 0.2cm 3 g -1 , the average pore size is 1.6nm, and the mass fraction of selenium in the prepared selenium-microporous ferric oxide composite is 30%.

[0062] The preparation method of selenium-microporous ferric oxide complex is as follows:

[0063] (1) Weigh selenium and microporous ferric oxide according to the mass ratio of 3:7 and mix them evenly;

[0064] (2) The mixture of selenium and microporous ferric oxide was heated at 3°C min -1 The heating rate is heated to 230 ° C and maintained for 5 hours, so that selenium is fully dispersed in the microporous ferric oxide;

[0065] (3) Stop heating and return to room temperature to obtain a selenium-microporous ferric oxide complex.

[0066] (2) P...

Embodiment 3

[0073] (1) Preparation of selenium-microporous support composite positive electrode

[0074] The microporous carrier used in the experiment is a microporous metal-organic framework coordination polymer (MIL-100(Cr), which is a coordination polymer formed by chromium and trimesic acid, purchased from Materiaux Institut Lavoisier Company), and the specific surface area 4000m 2 g -1 , the pore volume is 2cm 3 g -1 , the average pore size is 1.2nm, and the mass fraction of selenium in the prepared selenium-microporous metal-organic framework composite is 80%.

[0075] The preparation method of the selenium-microporous metal-organic framework composite is as follows:

[0076] (1) Weigh the selenium and the microporous metal-organic framework according to the mass ratio of 4:1 and mix them uniformly;

[0077] (2) The mixture of selenium and microporous MOFs was heated at 8°C min-1 The heating rate is heated to 265 ° C and maintained for 18 hours, so that selenium is fully dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com