Rare earth permanent magnetic alloy and magnetic phase composite preparation method thereof

A rare earth permanent magnet and permanent magnet alloy technology, applied in magnetic materials, magnetic objects, electrical components, etc., can solve the problems of complex process, high equipment cost, limited application and promotion, etc., to reduce sintering temperature, reduce production cost, Achieving the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

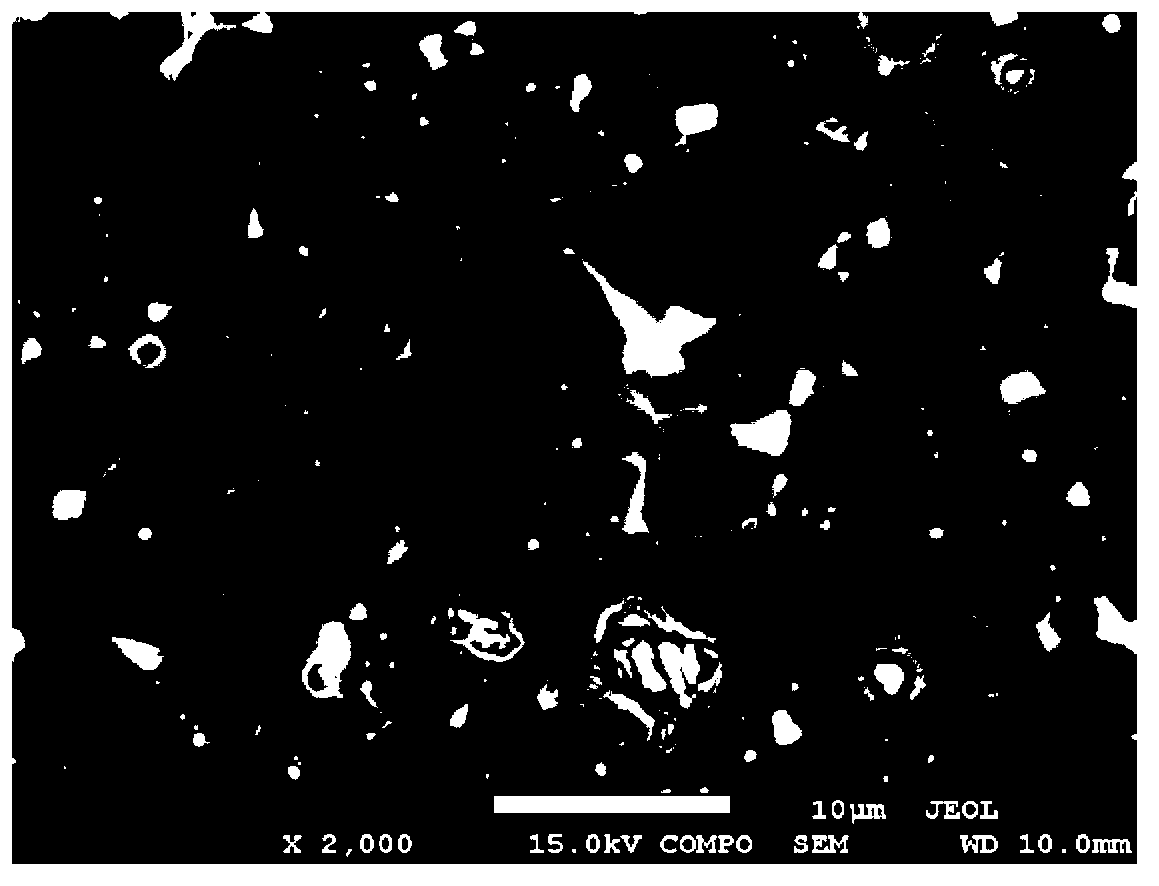

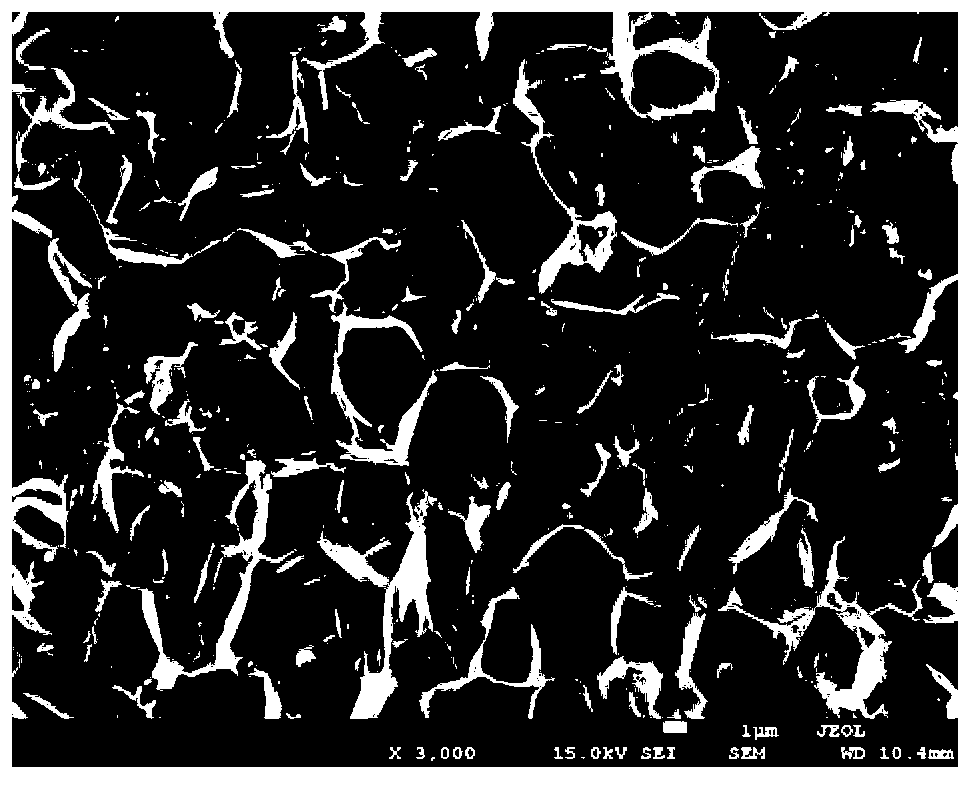

Image

Examples

Embodiment 1

[0036] Adopt the method of the present invention to prepare chemical composition to be (Nd 0.9 Dy 0.1 ) 30 Fe bal B 1 Rare earth permanent magnet alloy with composite magnetic phase, wherein bal is the balance, and the mass percentage of heavy rare earth Dy is 3%.

[0037] Step 1: According to the mass percentage Nd 30 Fe bal B 1 and (Nd 0.8 Dy 0.2 ) 30 Fe bal B 1 Prepare raw materials separately.

[0038] Step 2: Melt the prepared raw materials separately to prepare quick-setting belts. First put the raw materials into the crucible of the quick-setting furnace, and conduct vacuum induction melting under the protection of argon. After the raw materials are fully melted to form an alloy, keep the temperature at 1500°C, and pour the alloy liquid onto a water-cooled copper roller with a line speed of 3 m / s. Above, two quick-setting sheets with a thickness of 0.3 mm were prepared.

[0039] Step 3: crushing powder: Nd prepared in step 2 30 Fe bal B 1 and (Nd 0.8 D...

Embodiment 2

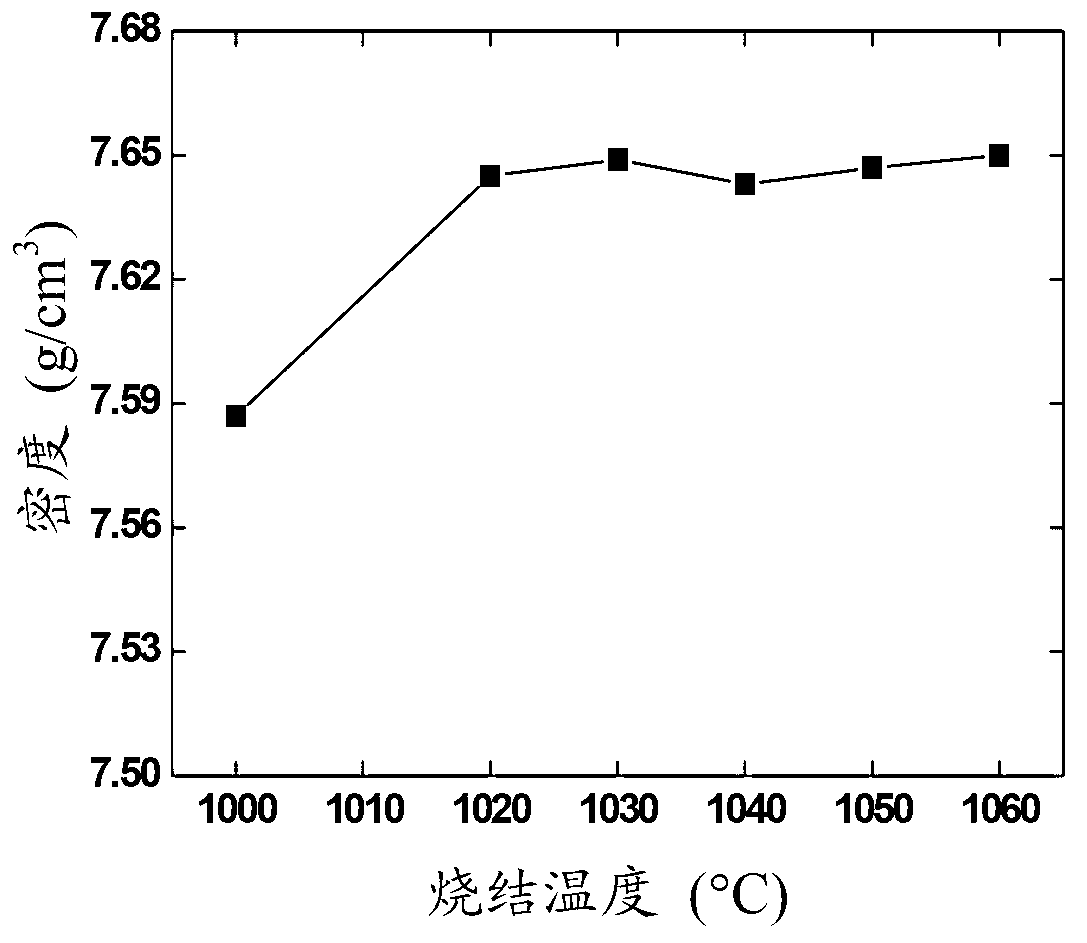

[0044] Low temperature sintering preparation design composition is (Nd 0.8 Ce 0.2 ) 30 Fe bal B 1 The magnet, wherein the rare earth Nd mass percentage content is 24%, the mass percentage content of Ce is 6%, and the total rare earth content is 30%.

[0045] Step 1: According to the mass percentage Nd 30 Fe bal B 1 and (Nd 0.7 Ce 0.3 ) 30 Fe bal B 1 Prepare raw materials separately.

[0046] Step 2: Melt the prepared raw materials separately to prepare quick-setting belts. First put the raw materials into the crucible of the quick-setting furnace, and conduct vacuum induction melting under the protection of argon. After the raw materials are fully melted to form an alloy, keep the temperature at 1400 ° C, and pour the alloy liquid onto a water-cooled copper roller with a line speed of 3 m / s Above, two quick-setting sheets with a thickness of 0.3 mm were prepared.

[0047] Step 3: Crushing and milling: the produced Nd 30 Fe bal B 1 and (Nd 0.7 Ce 0.3 ) 30 Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com