Process condition for extracting proteins of Northeast China carya cathayensis mandshurica seeds

A process condition and technology of walnut catalpa, which is applied in the field of extracting protein from Northeast hickory catalpa seed kernels, can solve the problems of rare research on protein extraction of Northeast hickory catalpa, and achieve the effects of cost saving, good resolubility, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

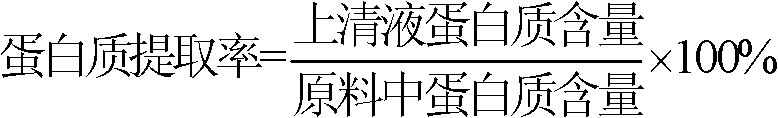

Method used

Image

Examples

Embodiment 1

[0029] After crushing 1Kg of dried seed kernels through a 40-mesh sieve, pass through supercritical CO 2 Degreasing, the operating conditions are pressure 35MPa, temperature 40°C, time 2.5 hours, a total of 3 extractions to fully remove grease. Add 0.01mol / L NaOH extract (solid-liquid ratio 1 / 30) to the degreased Hickory catalpa powder, stir and extract in a 45°C water bath for 1.5h, centrifuge and continue to extract 1.5h with the extract under the same conditions for precipitation. Centrifuge and combine the two extraction supernatants. It was determined that the protein extraction rate reached 84.36%. Use 0.1mol / L HCl and NaOH solution to adjust the pH of the extracted protein solution to the isoelectric point of 4.5, stir evenly to fully precipitate the protein, and centrifuge again. Take the precipitate, adjust the pH of the precipitate to neutral, and then use dialysis to remove the salt ions in the protein solution. The protein after dialysis and desalination is vacu...

Embodiment 2

[0033] After crushing 1Kg of dried seed kernels through a 40-mesh sieve, pass through supercritical CO 2 Degreasing, the operating conditions are pressure 35MPa, temperature 40°C, time 2.5 hours, a total of 3 extractions to fully remove grease. Add 0.01mol / L NaOH extract (solid-liquid ratio 1 / 30) to the degreased Hickory catalpa powder, stir and extract in a 45°C water bath for 2 hours, centrifuge and continue to extract the precipitate for 2 hours under the same conditions with the extract, centrifuge, Combine the two extraction supernatants. It was determined that the protein extraction rate reached 83.17%. Use 0.1mol / L HCl and NaOH solution to adjust the pH of the extracted protein solution to the isoelectric point of 4.5, stir evenly to fully precipitate the protein, and centrifuge again. Take the precipitate, adjust the pH of the precipitate to neutral, and then use dialysis to remove the salt ions in the protein solution. The protein after dialysis and desalination is...

Embodiment 3

[0035] After crushing 1Kg of dried seed kernels through a 40-mesh sieve, pass through supercritical CO 2 Degreasing, the operating conditions are pressure 35MPa, temperature 40°C, time 2.5 hours, a total of 3 extractions to fully remove grease. Add 0.02mol / L NaOH extract (solid-liquid ratio 1 / 30) to the degreased Hickory catalpa powder, stir and extract in a 50°C water bath for 1.5h, centrifuge and continue to extract 1.5h with the extract under the same conditions for precipitation. Centrifuge and combine the two extraction supernatants. It was determined that the protein extraction rate reached 88.98%. Use 0.1mol / L HCl and NaOH solution to adjust the pH of the extracted protein solution to the isoelectric point of 4.5, stir evenly to fully precipitate the protein, and centrifuge again. Take the precipitate, adjust the pH of the precipitate to neutral, and then use dialysis to remove the salt ions in the protein solution. The protein after dialysis and desalination is vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com