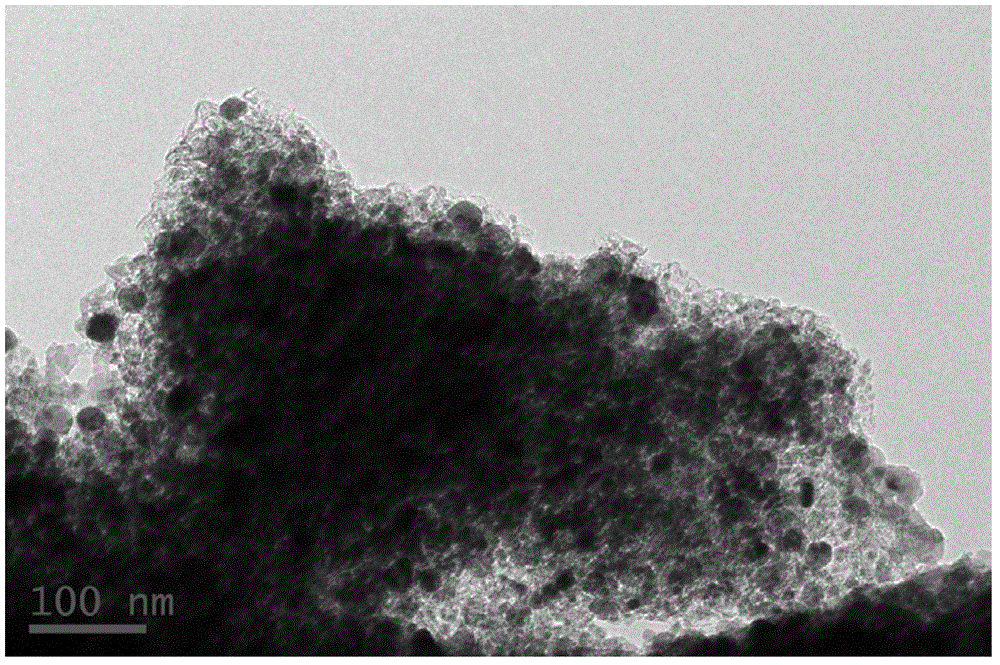

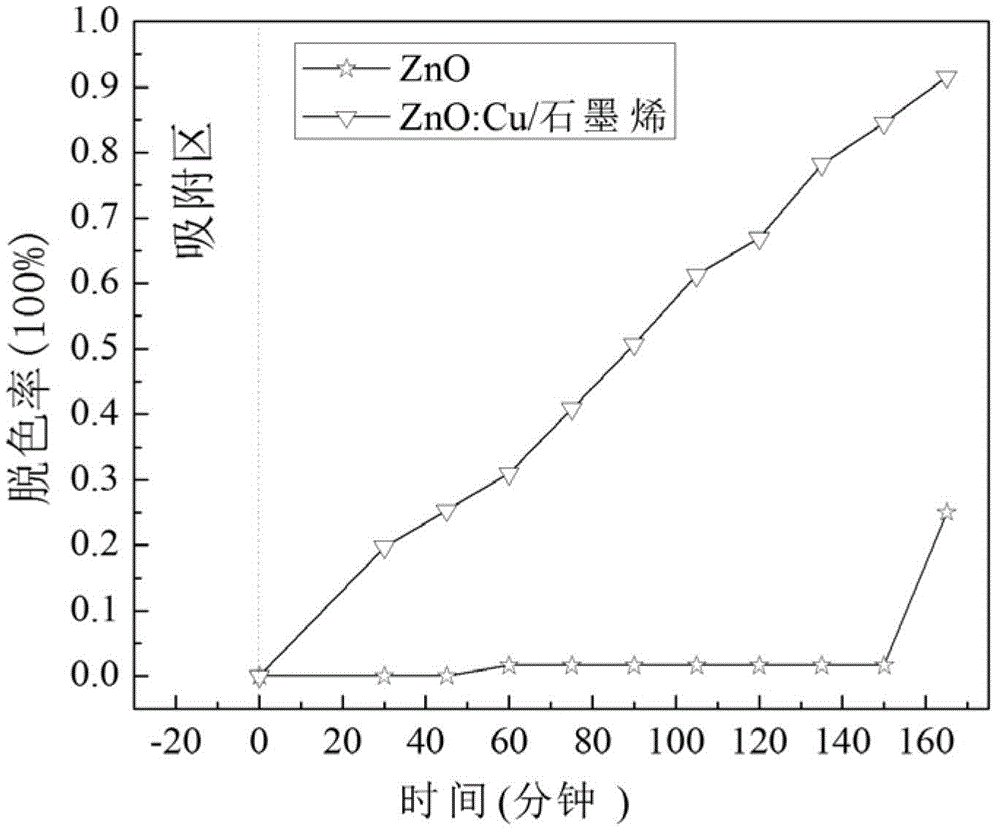

Cu-doped ZnO/graphene composite photocatalyst and preparation method thereof

A graphene composite and photocatalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as constraints, achieve good application prospects, uniform grain size distribution, and promote adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 10mg of graphite oxide and 0.219g of cetyltrimethylammonium bromide and mix them in 20ml of water, and process them in an ultrasonic machine with a frequency of 40KHz and a power of 120W for 30 minutes to obtain a precursor reactant one; 3.951g of zinc acetate and 0.3993g of copper acetate was dissolved in 80ml of distilled water, and ultrasonically treated for 20 minutes to obtain precursor reactant II; 2.243g of hexamethylenetetramine and 0.4705g of sodium citrate were dissolved in 100ml of distilled water, and ultrasonically treated for 20 minutes to obtain precursor Reactant three.

[0027] Precursor reactant 1 and precursor reactant 2 were mixed, and after being ultrasonically treated for 10 minutes, they were poured into a three-necked flask. Pour the precursor reactant three into the constant pressure funnel. The three-neck flask and the constant pressure funnel were placed in a constant temperature magnetic stirring oil bath to allow the reactants in the ...

Embodiment 2

[0030] Weigh 15mg of graphite oxide and 0.323g of hexadecyltrimethylammonium bromide, mix them in 15ml of distilled water, and ultrasonically treat them for 40 minutes to obtain precursor reactant 1; dissolve 3.951g of zinc acetate and 0.1997g of copper acetate in 80ml of In distilled water, sonicate for 30 minutes to obtain precursor reactant 2; dissolve 2.243 g of hexamethylenetetramine and 0.4705 g of sodium citrate in 100 ml of distilled water, and sonicate for 20 minutes to obtain precursor reactant 3.

[0031] The precursor reactant 1 and the precursor reactant 2 were mixed, treated in an ultrasonic machine with a frequency of 40KHz and a power of 120W for 30 minutes, and poured into a three-necked flask. Pour the precursor reactant three into the constant pressure funnel. The three-neck flask and the constant pressure funnel were placed in a constant temperature magnetic stirring oil bath to allow the reactants in the two to react. The temperature of the oil bath was c...

Embodiment 3

[0034] Weigh 20mg of graphite oxide and 0.427g of hexadecyltrimethylammonium bromide, mix them in 20ml of distilled water, and ultrasonicate for 40 minutes to obtain precursor reactant 1; dissolve 3.951g of zinc acetate and 0.2995g of copper acetate in 80ml of distilled water , sonicate for 30 minutes to obtain precursor reactant 2; dissolve 4.486 g of hexamethylenetetramine and 0.4705 g of sodium citrate in 100 ml of distilled water, and sonicate for 20 minutes to obtain precursor reactant 3.

[0035] The precursor reactant 1 and the precursor reactant 2 were mixed, treated in an ultrasonic machine with a frequency of 40KHz and a power of 120W for 30 minutes, and poured into a three-necked flask. Pour the precursor reactant three into the constant pressure funnel. The three-neck flask and the constant pressure funnel were placed in a constant temperature magnetic stirring oil bath to allow the reactants in the two to react. The temperature of the oil bath is controlled at 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com