Production method and application of terephthalic metal slat whisker

A technology of terephthalic acid and crude terephthalic acid, which is applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of low purity of terephthalic acid and limitations in application fields, and achieve environmental benefits and economic benefits Taking into account both benefits, solving high processing costs, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

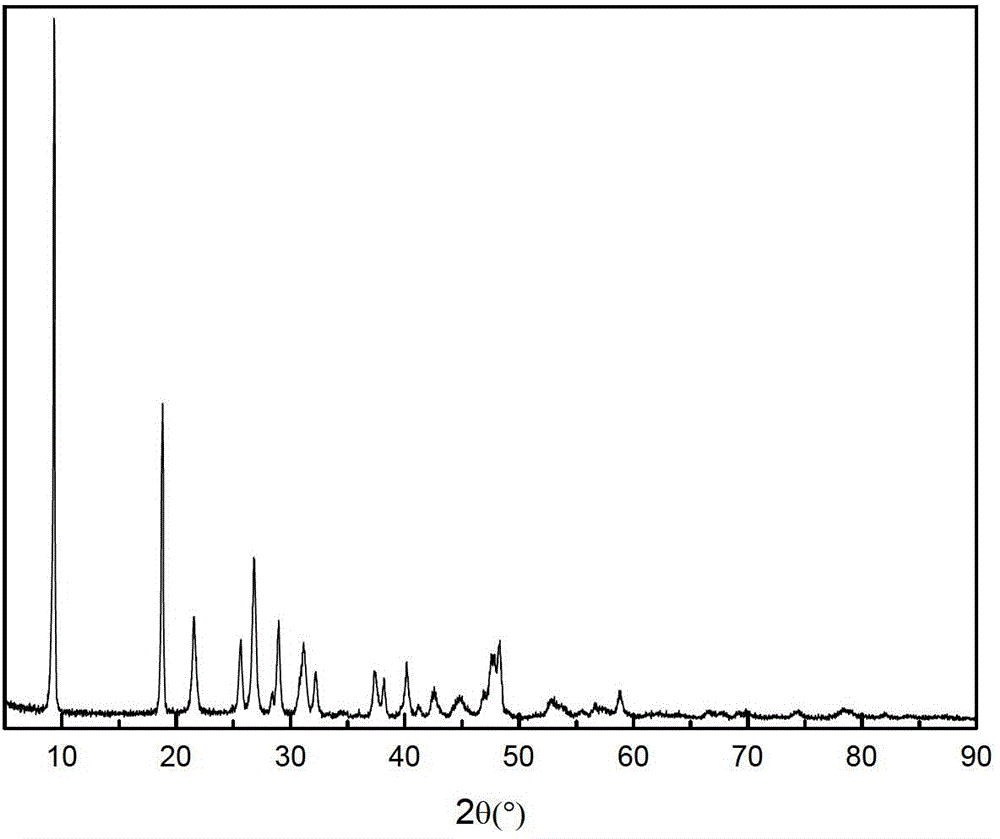

Image

Examples

Embodiment 1

[0022] Adjust the pH value of the wastewater to 11, add 20% basic aluminum chloride, and then the wastewater first undergoes rapid stirring at 500 rpm for 6 minutes, and then slow stirring at 100 rpm for 6 minutes to obtain flocs The waste water was filtered by waste coal slag, and then 30% activated carbon was added to the waste water. After 10 minutes of adsorption, the activated carbon was filtered through a layer of waste coal slag, and the waste water was stirred at 150 rpm for 6 minutes. At the same time, it was added to the waste water Dilute sulfuric acid, wait for the pH value of the wastewater to drop to 3, and age in the aging tank for 5 hours to obtain crude terephthalic acid. After testing, the purity of terephthalic acid reached 95%.

[0023] The crude terephthalic acid obtained in Example 1 is added to caustic soda solution to dissolve again, adjust the pH value at 8, add polyethylene glycol nonionic surfactant, stir and mix, then add soluble metal salt CaCl 2, ...

Embodiment 2

[0025] Adjust the pH value of the wastewater to 10, add 5% basic aluminum chloride, and then the wastewater first undergoes rapid stirring at 350 rpm for 10 minutes, and then slow stirring at 120 rpm for 5 minutes to obtain flocs The waste water is filtered through the waste coal slag to filter the sediment, and then 10% activated carbon is added to the waste water. After 5 days of adsorption, the activated carbon is filtered through a layer of waste coal slag, and the waste water is stirred at 80 rpm for 10 minutes, and at the same time, the waste water is added to the waste water. Hydrochloric acid, after the pH value of the wastewater drops to 3, it is aged in the aging tank for 1, and the purity of the obtained crude terephthalic acid can reach 95%.

[0026] Add the obtained crude terephthalic acid into caustic soda solution to dissolve again, adjust the pH value at 6, add polyoxyethylene type nonionic surfactant, stir and mix, then add soluble metal salt MgCl 2, stir, and ...

Embodiment 3

[0028] Adjust the pH value of the wastewater to 10, add 13% basic aluminum chloride, and then the wastewater first undergoes rapid stirring at 550 rpm for 5 minutes, and then slow stirring at 80 rpm for 10 minutes to obtain flocs The waste water was filtered through the waste coal slag to filter the sediment, and then 20% activated carbon was added to the waste water. After 8 minutes of adsorption, the activated carbon was filtered through a layer of waste coal slag, and the waste water was stirred at 130 rpm for 5 minutes. Hydrochloric acid, after the pH value of the wastewater drops to 3, it is aged in the aging tank for 3 hours, and the purity of the obtained crude terephthalic acid can reach 95%.

[0029] Add the obtained crude terephthalic acid into caustic soda solution to dissolve again, adjust the pH value at 7, add polyoxyethylene type or polyol type nonionic surfactant, stir and mix, then add soluble metal salt ZnCl 2, stir, After aging for 3 hours, zinc terephthalat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com