Novel aluminum material with microscale self-driven dropwise condensation function and preparation method thereof

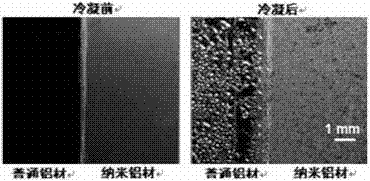

A droplet condensation and self-driven technology, applied in the field of material science, can solve the problems of micro-droplets detached from the surface, and the research has not been reported yet, and achieve the effect of short cycle, good reproducibility, and excellent superhydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

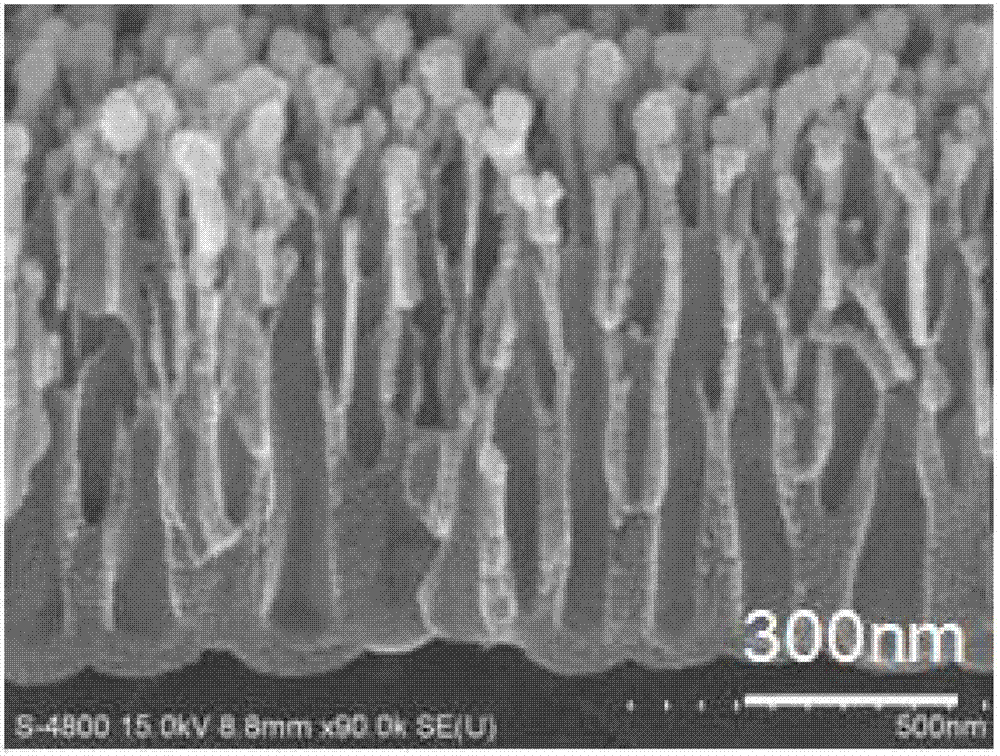

[0041] (1) Remove the organic grease and inorganic impurities on the surface of the aluminum foil by cleaning or grinding, or use the aluminum foil directly without any treatment.

[0042] (2) With aluminum foil as the anode and platinum electrode as the cathode, the distance between the two electrodes was controlled to be 4 cm, and the phosphoric acid solution with 2 volume fraction was used as the electrolyte to carry out variable voltage oxidation in a constant temperature water bath at 30 °C (control the appropriate rise The pressure rate increases the voltage from 25 V to 110 V, such as 0.5 V / 10s), and the oxidation continues for 100s after the current rises to 1.0 A.

[0043] (3) Electrochemically anodized aluminum foil with N 2 blow dry.

[0044] (4) Then put it into a covered container, drop a drop of fluorosilane in the container, cover the container and put it in an oven at 150 °C for 2 hours. After 2 hours, take the sample out of the oven and cool it to room temper...

Embodiment 2

[0046] (1) Remove organic grease and inorganic impurities on the surface of aluminum foil by cleaning or grinding;

[0047] (2) With the aluminum foil as the anode and the platinum electrode as the cathode, the distance between the two electrodes was controlled to be 5 cm, and 0.3 M oxalic acid solution was used as the electrolyte to carry out constant current oxidation in a constant temperature water bath at 30 °C for 30 min, and the current was kept at 0.4 About A, oxidized for 500 s.

[0048] (3) Put the electrochemically anodized aluminum foil into a covered container, drop a drop of fluorosilane in the container, cover the container and put it in an oven at 100 °C for 2 h, and remove it from the oven after 2 h Take out the sample and cool it down to room temperature, and you can get the aluminum foil with excellent superhydrophobic properties on the surface.

Embodiment 3

[0050] (1) Remove organic grease and inorganic impurities on the surface of aluminum foil by cleaning or grinding.

[0051] (2) Using aluminum foil as the anode and platinum electrode as the cathode, the distance between the two electrodes was controlled to be 4 cm, and 0.3 M sulfuric acid solution was used as the electrolyte to carry out variable voltage oxidation in a constant temperature water bath at 30 °C (control the appropriate boost rate Make the voltage rise from 25 V to 110 V, such as 0.5 V / 5s), and oxidize for 60 s.

[0052] (3) Put the electrochemically anodized aluminum foil into a covered container, drop a drop of FAS in the container, cover the container and put it in an oven at 150 °C for 1 h, take it out of the oven after 1 h The aluminum foil with excellent superhydrophobic properties on the surface can be obtained after the sample is cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com