Cutting tool for improving coating structure and preparation method thereof

A cutting tool and coating technology, which is applied in the field of cutting tools and its preparation process, can solve the problems of no comprehensive consideration of the influence effect, no in-depth research and description of grain size, etc., and achieve excellent anti-oxidation and crater wear resistance , Improve nucleation uniformity and density, and reduce roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

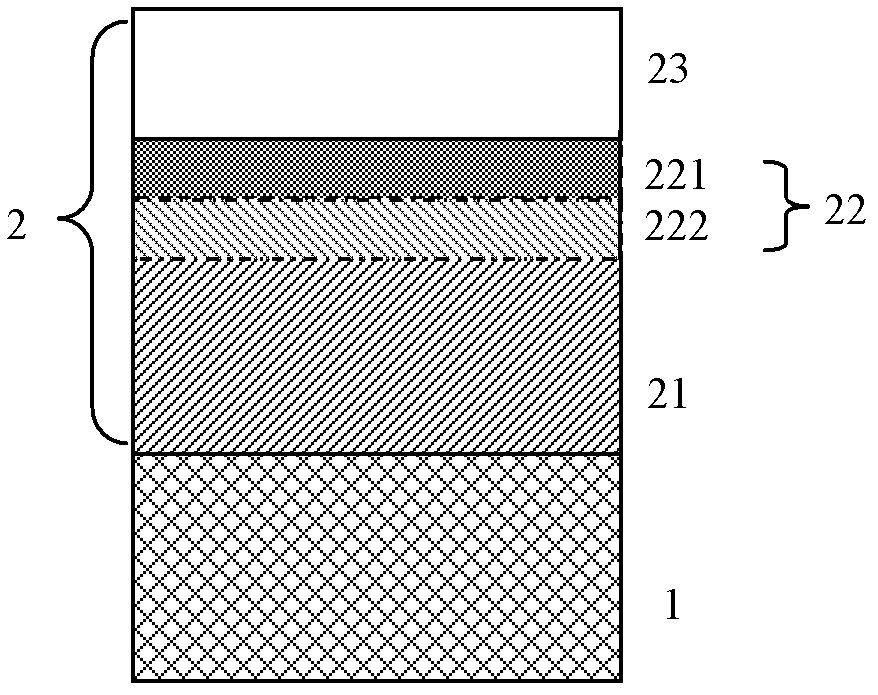

[0048] a kind of like figure 1 The cutting tool with improved coating structure of the present invention shown includes a substrate A1 and a coating 2 at least partially covered on the substrate A1. The coating 2 includes at least an inner layer B21, a transition layer C22 and an outer layer from the inside to the outside. D23.

[0049] in:

[0050] The inner layer B21 is mainly composed of MT-TiCN material with a thickness of 6 μm;

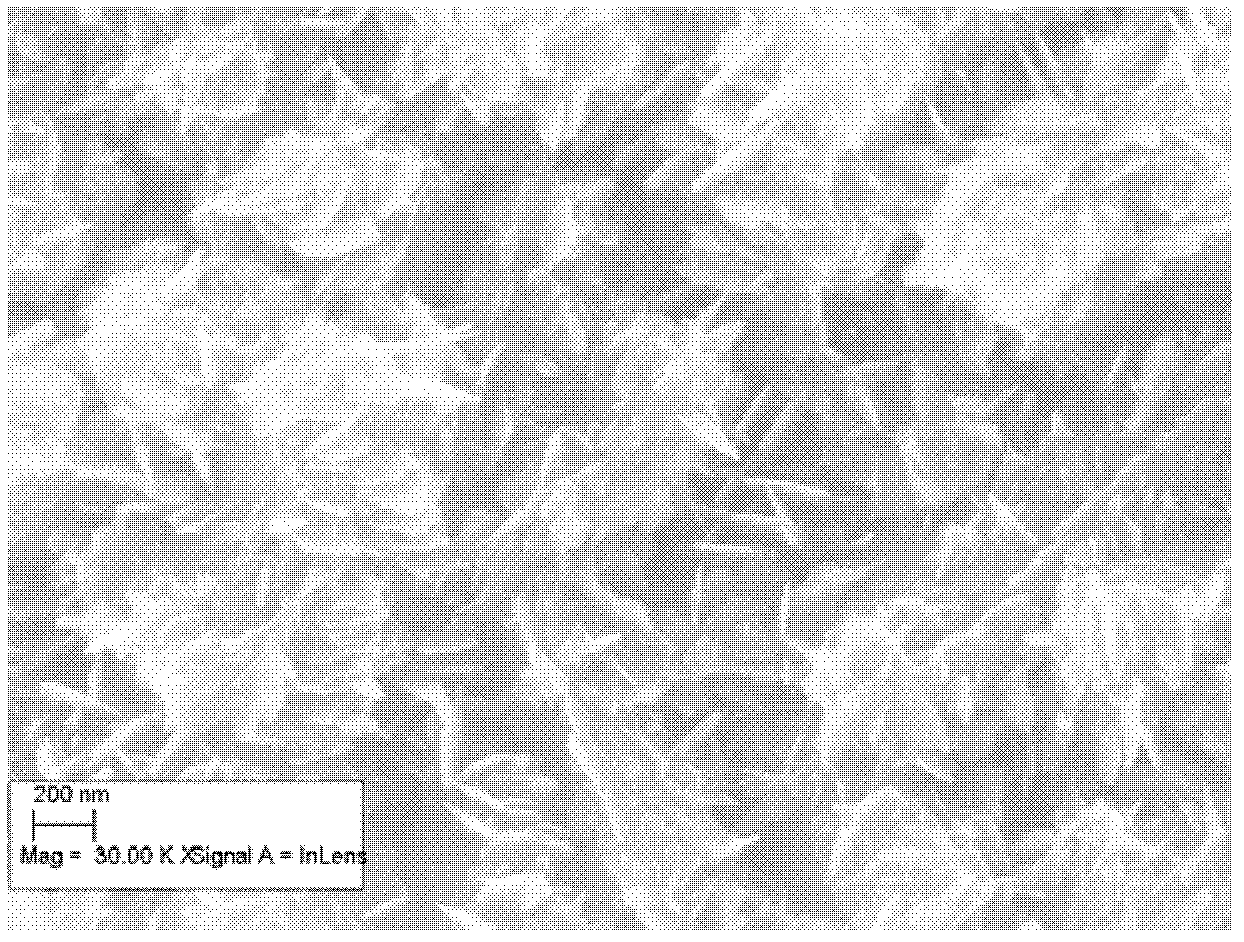

[0051] The outer layer D23 is mainly composed of α-Al 2 o 3 Material composition, thickness d=4μm, outer layer D23 is an ultra-fine-grained oxide coating, outer layer D of α-Al2 o 3 The average grain size S is 0.46μm;

[0052] Transition layer C22 includes transition layer C1 221 and transition layer C2 222 from outside to inside:

[0053] The transition layer C1 221 is mainly composed of titanium carbonitride TiC x1 N y1 o z1 Composition (specifically TiC 0.5 o 0.5 ), x1, y1, z1 represent TiC x1 N y1 o z1 The atomic percentages of ...

Embodiment 2

[0067] a kind of like figure 1 The cutting tool with improved coating structure of the present invention shown has the same coating structure, composition, microscopic composition, etc. as the cutting tool in Example 1, except that the outer layer α-Al 2 o 3 It is slightly different from Example 1. In this embodiment, the thickness d of the outer layer D is 2 μm, and the average grain size S is 0.4 μm. The preparation method of the present embodiment 2 is basically the same as that of the embodiment 1, only need to make adaptive adjustments on the process parameters.

Embodiment 3

[0069] a kind of like figure 1 The cutting tool with improved coating structure of the present invention shown includes a substrate A1 and a coating 2 at least partially covered on the substrate A1. The coating 2 includes at least an inner layer B21, a transition layer C22 and an outer layer from the inside to the outside. D23;

[0070] in:

[0071] The inner layer B21 is mainly composed of MT-TiCN material with a thickness of 4 μm;

[0072] The outer layer D23 is mainly composed of α-Al 2 o 3 Composed of materials, the thickness is d=3μm, the outer layer D23 is an ultra-fine-grained oxide coating, and the outer layer D is α-Al 2 o 3 The average grain size S is 0.49μm;

[0073] Transition layer C22 includes transition layer C1 221 and transition layer C2 222 from outside to inside:

[0074] The transition layer C1 221 is mainly composed of titanium carbonitride TiC x1 N y1 o z1 Composition (specifically TiC 0.3 o 0.7 ), namely x1=0.3, y1=0, z1=0.7, z1 / (x1+y1+z1)=0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com