Batch hot-dip galvanizing smokeless flux and its application method

A technology of hot-dip galvanizing and flux, which is applied in the fields of batch hot-dip galvanizing smokeless flux, metal surface treatment, and batch hot-dip galvanizing flux. Plating and other problems to achieve the effect of speeding up the amount of adhesion, avoiding missing plating, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

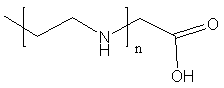

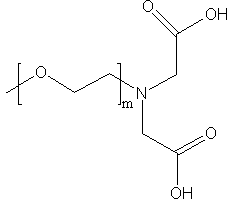

[0035] The batch hot-dip galvanizing smokeless plating flux of the present invention consists of the following components: 70 g / L of zinc chloride, 30 g / L of aluminum chloride, 5 g / L of sodium fluorosilicate, and 5 g / L of ammonia carboxyl compound. L, nonionic surfactant 2g / L, cationic surfactant 2g / L. Among them, R in the aminocarboxyl compound 1 In the molecular structure formula n=0, R 2 In the molecular structural formula, m=0; when the nonionic surfactant is fatty alcohol polyoxyethylene ether, R 3 is methyl, R 4 for C 2 Long-chain alkyl, m value is 2, n value is 25; R in cationic surfactant 9 is methyl, R 7 for C 6 long chain alkyl, R 6 , R 8 is a methyl group, and X is a halide ion.

Embodiment 2

[0037] The batch hot-dip galvanizing smokeless fluxing agent of the present invention is made up of following components: zinc chloride 70g / L, aluminum chloride 30g / L, sodium fluorosilicate 5g / L, ammonia carboxyl compound 10g / L L, nonionic surfactant 2g / L, cationic surfactant 3g / L. Among them, R in the aminocarboxyl compound 1 In the molecular structure formula n=1, R 2 In the molecular structural formula, m=1; when the nonionic surfactant is fatty alcohol polyoxyethylene ether, R 3 is ethyl, R 4 for C 3 Long-chain alkyl, m takes the value of 1, and n takes the value of 15; R in the cationic surfactant 9 is ethyl, R 7 for C 7 long chain alkyl, R 6 , R 8 is a methyl group, and X is a halide ion.

Embodiment 3

[0039] The batch hot-dip galvanizing smokeless plating flux of the present invention consists of the following components: 70 g / L of zinc chloride, 30 g / L of aluminum chloride, 5 g / L of sodium fluorosilicate, and 20 g / L of ammonia carboxyl compound. L, nonionic surfactant 2g / L, cationic surfactant 4g / L. Among them, R in the aminocarboxyl compound 1 In the molecular structure formula n=2, R 2In the molecular structural formula, m=2; when the nonionic surfactant is fatty alcohol polyoxyethylene ether, R 3 is propyl, R 4 for C 4 Long-chain alkyl, m takes the value of 0, and n takes the value of 10; in cationic surfactants, R 9 is propyl, R 7 for C 8 long chain alkyl, R 6 , R 8 is a methyl group, and X is a halide ion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com