Preparation method of water-soluble strippable protective coating

A protective coating, water-soluble technology, applied in the field of preparation of water-soluble peelable protective coatings, can solve the problem of easy scratches and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 6 g of potassium persulfate and 5 g of n-dodecanethiol to 100 g of acrylic acid;

[0022] (2) Put the mixture container (such as a beaker) in a water bath at (65±2) ℃, and stir for 30 minutes; during this process, the viscosity will gradually increase, and water can be added to reduce the viscosity to facilitate stirring;

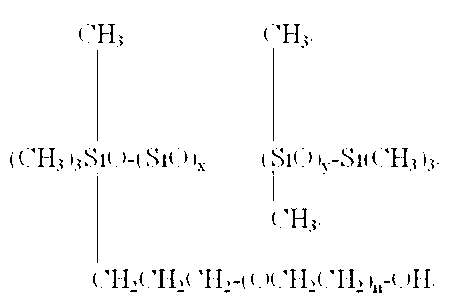

[0023] (3) Add 5 g of fumed silica and 1.5 g of water-soluble polyether-modified polysiloxane to the reaction product;

[0024] (4) Steps (1), (2) and (3) above to obtain component A;

[0025] (5) Polyethylene glycol with a molecular weight of 6000, as component B;

[0026] (6) Before construction, mix component A and component B at a ratio of 100:5, adjust to an appropriate viscosity with water, and then apply by brush;

[0027] (7) After the water in the coating evaporates, cure it in an oven at (70±5)°C for 10 minutes to obtain a peelable protective coating.

Embodiment 2

[0029] (1) Add 6 g of potassium persulfate and 5 g of n-dodecanethiol to 100 g of acrylic acid;

[0030] (2) Put the mixture container (such as a beaker) in a water bath at (65±2) ℃, and stir for 30 minutes; during this process, the viscosity will gradually increase, and water can be added to reduce the viscosity to facilitate stirring;

[0031] (3) Add 6 g of fumed silica and 1.5 g of water-soluble polyether-modified polysiloxane to the reaction product;

[0032] (4) Steps (1), (2) and (3) above to obtain component A;

[0033] (5) Polyethylene glycol with a molecular weight of 6000, as component B;

[0034] (6) Before construction, mix component A and component B at a ratio of 100:6 (mass fraction), adjust to an appropriate viscosity with water, and then apply by brush;

[0035] (7) After the water in the coating evaporates, cure it in an oven at (70±5)°C for 10 minutes to obtain a peelable protective coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com