Antiblocking parent stock for optical base film, and preparation method thereof

An anti-blocking masterbatch and anti-blocking agent technology, applied in the field of optical polyester film, can solve the problems of large difference in refractive index, no affinity, voids, etc., and achieve high light transmittance, easy realization, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An anti-blocking masterbatch for an optical base film, comprising the following components by weight percentage:

[0025] 90% powdered PET resin (intrinsic viscosity is 0.68dL / g, chromaticity b value is 1);

[0026] 10% polystyrene cross-linked microspheres (average particle size 8μm, refractive index 1.59);

[0027] 1) At room temperature, add powdered PET resin and anti-blocking agent into a high-speed dispersion mixer at a speed of 800-1500 rpm and mix for 15-20 minutes to form a mixture;

[0028] 2) Dry the mixture at 170°C for 4 hours. After drying, the water content is ≤50ppm (determination of trace moisture by differential pressure method).

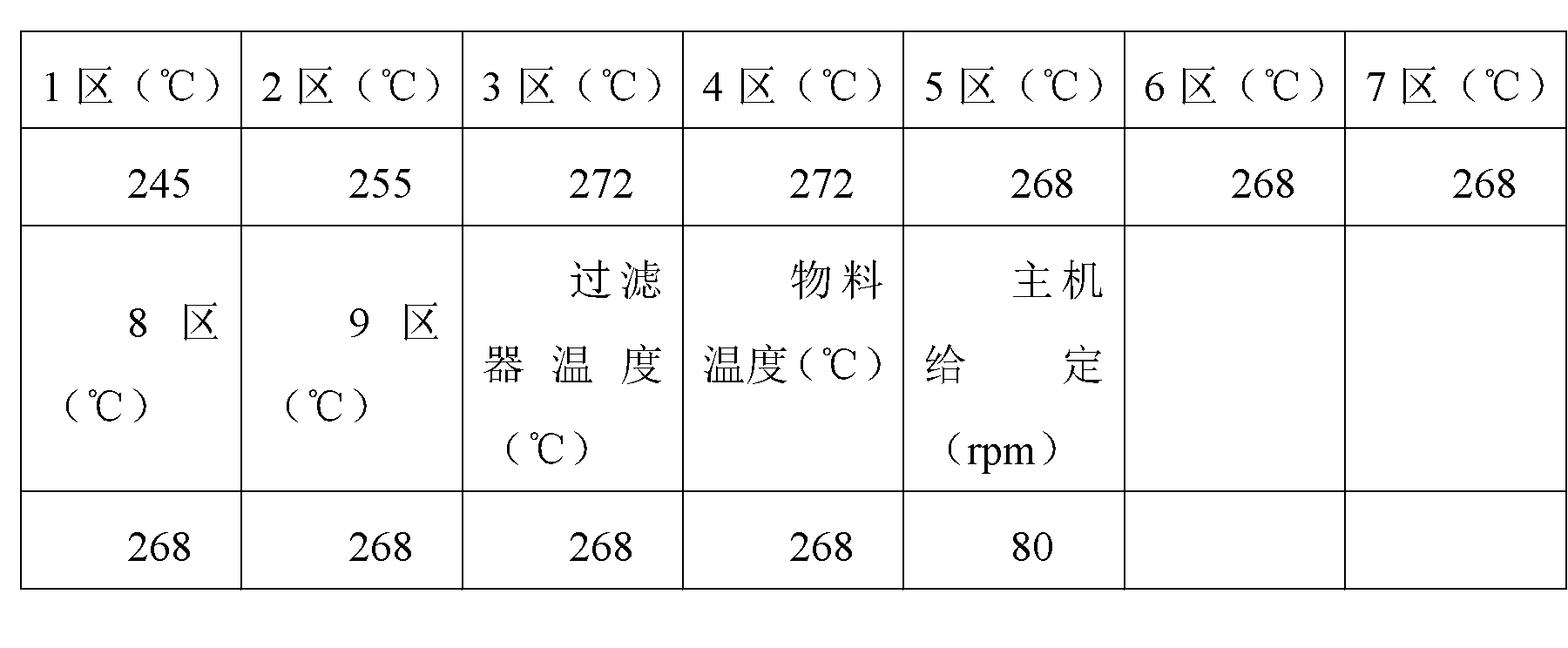

[0029] 3) Raise the twin-screw extruder to the temperature shown in Table 2, add the dried compound through the feeder of the twin-screw extruder, carry out melt extrusion, and cool and granulate.

[0030] Table 2 Extruder temperature settings

[0031]

[0032] 4) The masterbatch particles obtained in step 3) were drie...

Embodiment 2

[0034] An anti-blocking masterbatch for an optical base film, comprising the following components by weight percentage:

[0035] 90% powdered PET resin (intrinsic viscosity is 0.68dL / g, chromaticity b value is 1);

[0036] 10% polymethyl methacrylate cross-linked microspheres (average particle size 5 μm, refractive index 1.49);

[0037] Preparation method is the same as example 1.

Embodiment 3

[0039] An anti-blocking masterbatch for an optical base film, comprising the following components by weight percentage:

[0040] 90% powdered PET resin (intrinsic viscosity is 0.68dL / g, chromaticity b value is 1);

[0041] 6% polystyrene cross-linked microspheres (average particle size 6μm, refractive index 1.59);

[0042] 4% polymethyl methacrylate cross-linked microspheres (average particle size 5 μm, refractive index 1.49);

[0043] Preparation method is the same as example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com