Multifunctional porous purifying ceramic granular material and preparation method

A ceramic particle and multifunctional technology, applied in the field of environmental purification materials, can solve problems such as low adsorption rate, low bacterial inhibition rate, and little benefit to health, and achieve low reuse rate, easy saturation, and purification efficiency low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

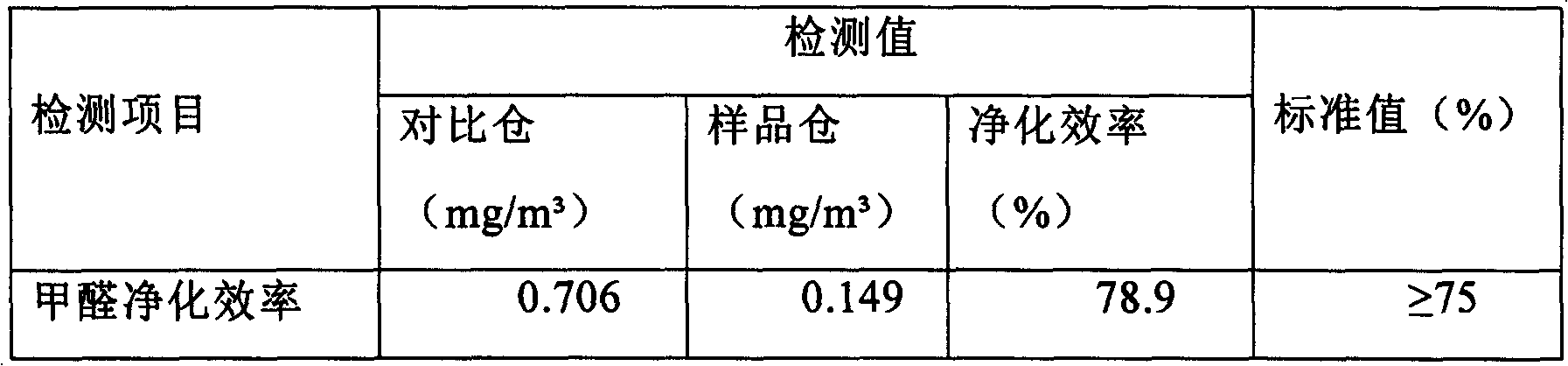

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A process flow of multifunctional porous and purified ceramic materials, which is divided into six processes according to the sequence: raw material, ball milling, mud sieving, pore making, shade drying, surface treatment, high-temperature calcination, impregnation, and low-temperature calcination;

[0030] Raw materials halloysite 40kg, zeolite 15kg, diatomite 25kg, alumina 20kg, nano-photocatalytic material 3kg, the nano-photocatalytic material is nano-titanium oxide / lanthanum oxide composite material;

[0031] Ball milling: Halloysite, zeolite, diatomaceous earth, and alumina are used as ball mills to pulverize the raw materials respectively;

[0032] Mud sieving: process the ground raw material with a certain proportion of water until the fineness reaches 200 mesh;

[0033] Pore making: immerse polyurethane foam particles with a porosity of 80PPI and a diameter of 5mm in the mud, and take them out after the polyurethane foam is absorbed and saturated;

[0034] Dr...

Embodiment 2

[0041] The technical process of a multifunctional porous purification ceramic material in the present invention is divided into six processes according to the sequence: raw material, ball milling, mud sieving, pore making, shade drying, high-temperature calcination, impregnation, and low-temperature calcination;

[0042] Raw materials halloysite 45kg, zeolite 15kg, diatomite 25kg, alumina 15kg, nano photocatalytic material 2kg, the nano photocatalytic material is nano tungsten oxide / praseodymium oxide composite material;

[0043] Ball milling: Halloysite, zeolite, diatomaceous earth, and alumina are used as ball mills to pulverize the raw materials respectively;

[0044] Mud sieving: process the ground raw material with a certain proportion of water until the fineness reaches 200 mesh;

[0045] Pore making: immerse the polyurethane board with a porosity of 90PPI and a size of 20×20×2.5cm into the mud, and take it out after the polyurethane foam is saturated;

[0046] Drying...

Embodiment 3

[0053] A process flow of multifunctional porous and purified ceramic materials, which is divided into six processes according to the sequence: raw material, ball milling, mud sieving, pore making, shade drying, surface treatment, high-temperature calcination, impregnation, and low-temperature calcination;

[0054] Raw materials halloysite 50kg, zeolite 20kg, diatomite 20kg, alumina 10kg, nano photocatalytic material 3kg, the nano photocatalytic material is nano zinc oxide / cerium oxide composite material;

[0055] Ball milling: Halloysite, zeolite, diatomaceous earth, and alumina are used as ball mills to pulverize the raw materials respectively;

[0056] Mud sieving: process the ground raw material with a certain proportion of water until the fineness reaches 200 mesh;

[0057] Pore making: immerse polyurethane foam particles with a porosity of 100PPI and a diameter of 10mm in the mud, and take them out after the polyurethane foam is absorbed and saturated;

[0058]Drying i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com